An analysis of the global development of mill production shows steady trends in the creation of modern mills with reduced structures. The introduction of reduced grinding structures into grinding practice allows to reduce the amount of equipment used and, as a result, significantly reduce the cost of mill production in general. However, the reduction of grinding structures within the framework of traditional technological approaches and traditional equipment inevitably entails a decrease in flour quality and yield. As a rule, most mill manufacturers compensate for this significant disadvantage by increasing grain quality requirements. This often comes as an unpleasant surprise to the customer when the equipment has already been purchased and delivered. At the same time, our company has solutions that are guaranteed to reduce the grinding structure and, consequently, the cost of the technology while ensuring its efficiency. In the vast majority of cases, our mills produce even better results than mills that implement advanced structures. We have paved this way by developing new technological operations and machines that implement them. The success of this approach has been ensured by our company’s many years of research and development and implementation work. Based on the materials of this work, in 2013, he defended his doctoral dissertation on “Scientific basis and practice of improving the efficiency of varietal bread milling of wheat”. The work was carried out at the National University of Food Technologies (Kyiv) and the Odesa National Academy of Food Technologies, and the results were widely tested by OLIS at flour mills in Ukraine and abroad.

Today, we manufacture wheat mills with a capacity of 30 tonnes per day to 500 tonnes per day and more, using a reduced grinding structure. The intensification of the processing process is ensured by the introduction of such operations as flattening, hulling, fractionation, as well as the use of special grain conditioning and milling modes. These processing features are ensured by a number of new machines, such as: debrinders of the Cascade design, grain surface cleaning machines MAO, flour sifters of the RMO-4 type, dismembrators ESM, grain heaters PZ, etc.

Types of mills

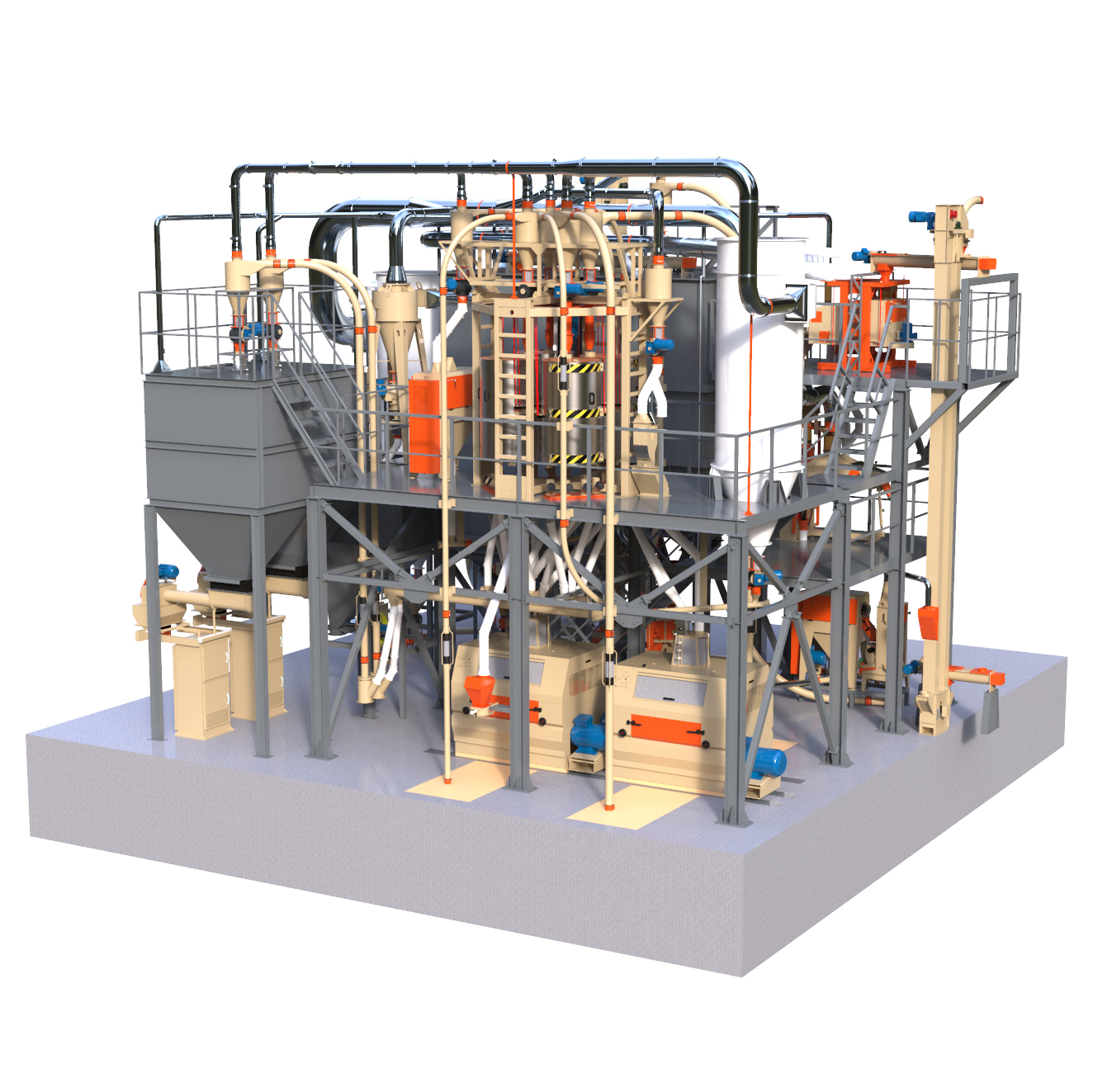

Mills can be divided into 2 types based on the type of equipment: aggregate and complete.

The sinter mills have a ready-made design for the placement of equipment in the steel structure and require minimal time for their installation and commissioning.

Complete mills can have different capacities, require the development of an individual process flow diagram and are equipped with a set of equipment in accordance with the capacity of the customer’s building.

We produce:

Mill plants from OLIS are a successful purchase for your business!