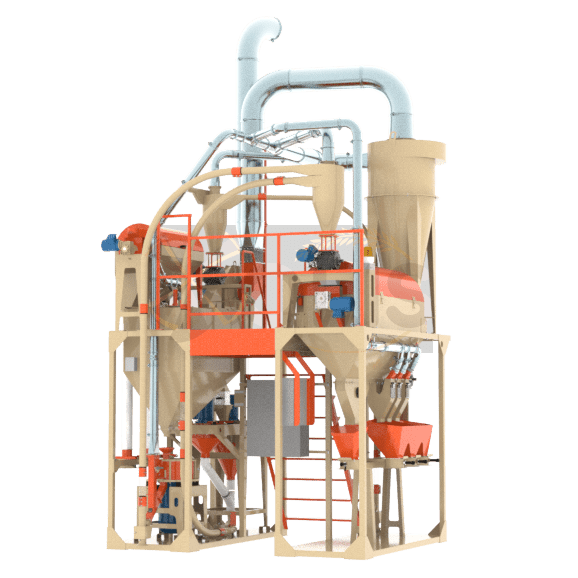

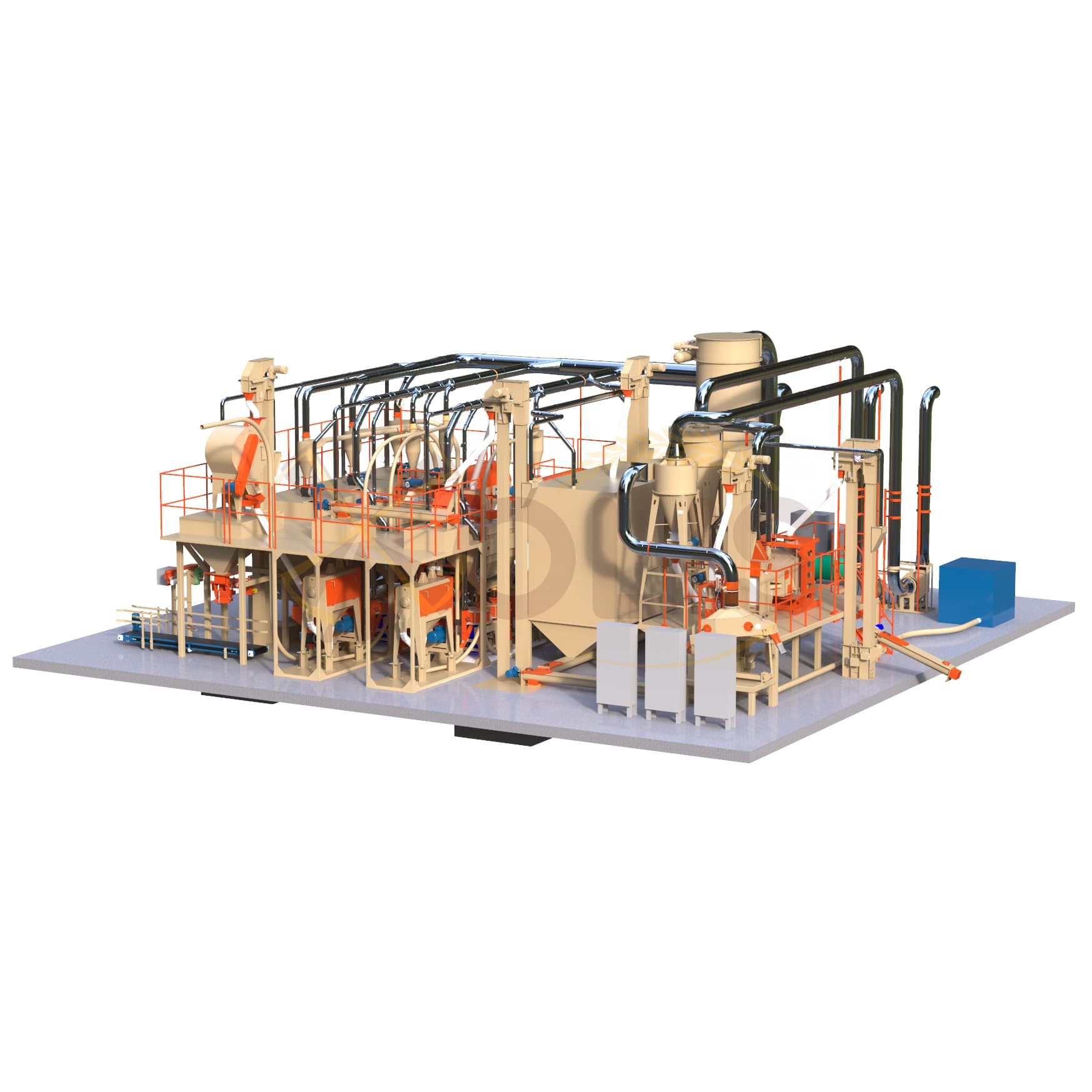

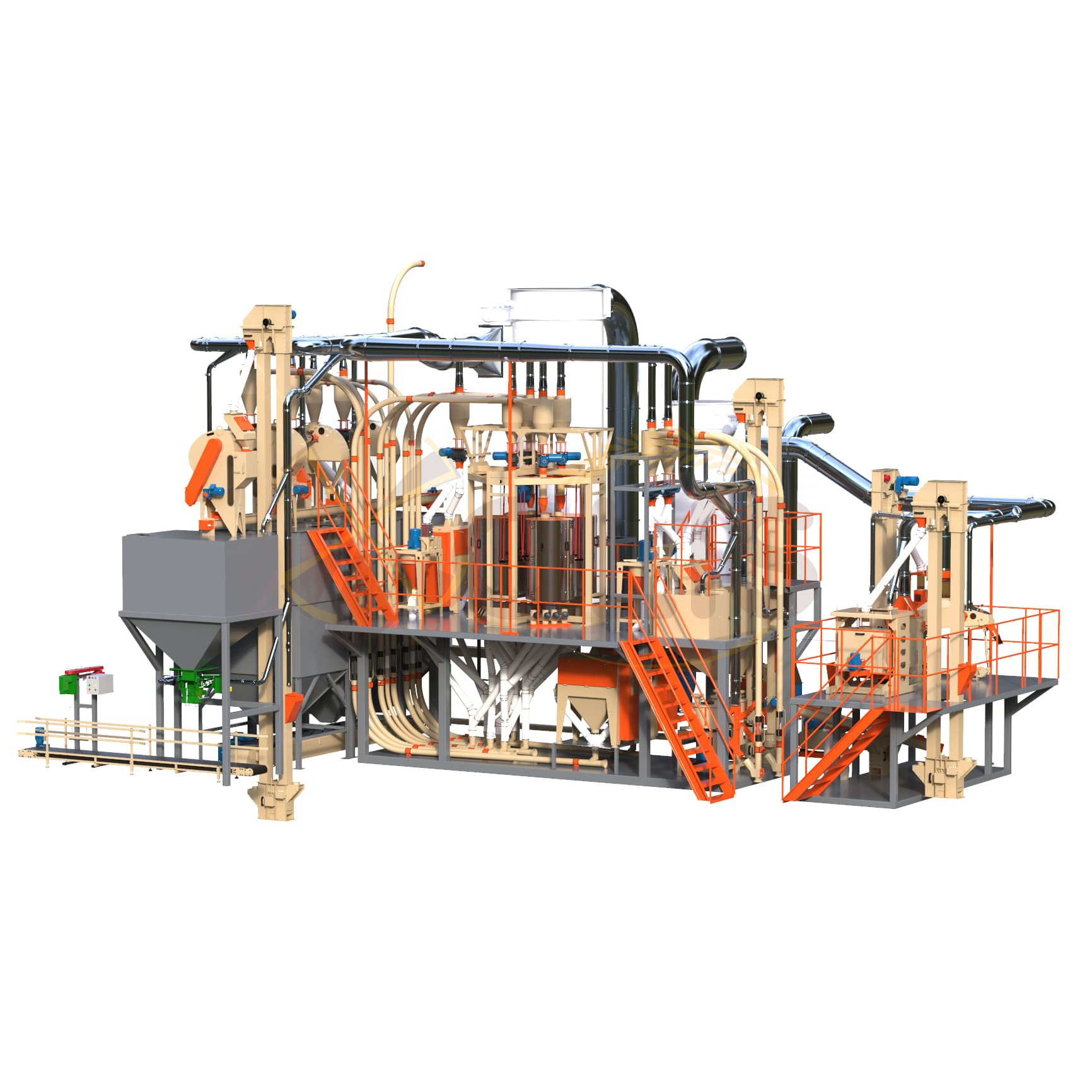

Multi-purpose complete groats production plant with productivity – 60 t/d

Purpose

The multipurpose complete groats production plant with productivity 60 t/day is designed for processing wheat, barley, peas, corn and millet into groats. Extended configuration of the groats production plant allows for automatic raw material accounting, industrial processing of millet and groats enrichment, as well as, if necessary, to receive only split peas. Equipping groats production plant provides an output and quality of groats is not below the requirements of current standards, which allows to meet the requirements of the market.

For placing the groats production plant, a 4-storey building with a floor height of at least 3 m and an area of each floor of at least 100 m2 is appropriate. In the absence of a appropriate building supporting steel framework to accommodate equipment is recommended to perform in the form of a four-tiered frame up to 9 m high with dimensions of 8 m x 12 m in plan and install on their own foundations. In this case, the external enclosures (walls and roof) it is advisable to arrange on reinforced concrete frameworks and foundations, independent of the load-bearing equipment of steel framework. The expected height of the building – 12 m. The structural part may be supplemented with rooms for the operator’s room, workshop laboratory, warehouses, etc.

As part of fulfilment individual project to the plant can be tied such utilities as:

- The receiving line of grain from vehicles and pre-cleaning;

- Warehouse placement and storage of the operative stock of grain with the line of its supply to the processing;

- Weight-unloading section with the possibility of selecting the finished product both in bags and in small packaging;

- Warehouse bulk storage of flours and husks with a line of loading on trucks;

The plant operate in automatic mode. The operator from the central control desk provides control of the plant.

Specifications

Assortment, output and productivity:

(The output of groats is specified when its quality is not less than the requirements established by GOST. Variation in the yield of cereals in the specified ranges depends on the quality of processed grain).

* – Grade of millet is determined by the class of processed millet.

**- with partial separation of the germ.

Characteristics

Voltage, 380W, 50Hz

Equipment composition:

Аdvantages

- Highest yield and quality of groats in the class of the multipurpose groats plant.

- Low energy consumption for raw material processing.

- Possibility of quick adjustment in case of change of type of processed grain or type of processed groats.

- Extended configuration of the grain mill allows you to record the raw material in automatic mode, to process grain industrially and carry out the enrichment of groats, and if necessary to get only chopped peas.

- Operation of the production plant is carried out in automatic mode.

- Reliable equipment ensures continuous and long-term operation of the production plant

Photo

Assortment, output and productivity:

(The output of groats is specified when its quality is not less than the requirements established by GOST. Variation in the yield of cereals in the specified ranges depends on the quality of processed grain).

* – Grade of millet is determined by the class of processed millet.

**- with partial separation of the germ.

Characteristics

Voltage, 380W, 50Hz

Equipment composition:

- Highest yield and quality of groats in the class of the multipurpose groats plant.

- Low energy consumption for raw material processing.

- Possibility of quick adjustment in case of change of type of processed grain or type of processed groats.

- Extended configuration of the grain mill allows you to record the raw material in automatic mode, to process grain industrially and carry out the enrichment of groats, and if necessary to get only chopped peas.

- Operation of the production plant is carried out in automatic mode.

- Reliable equipment ensures continuous and long-term operation of the production plant