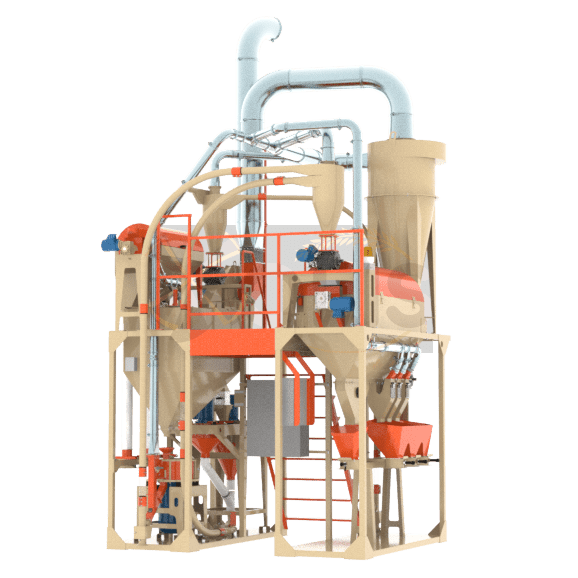

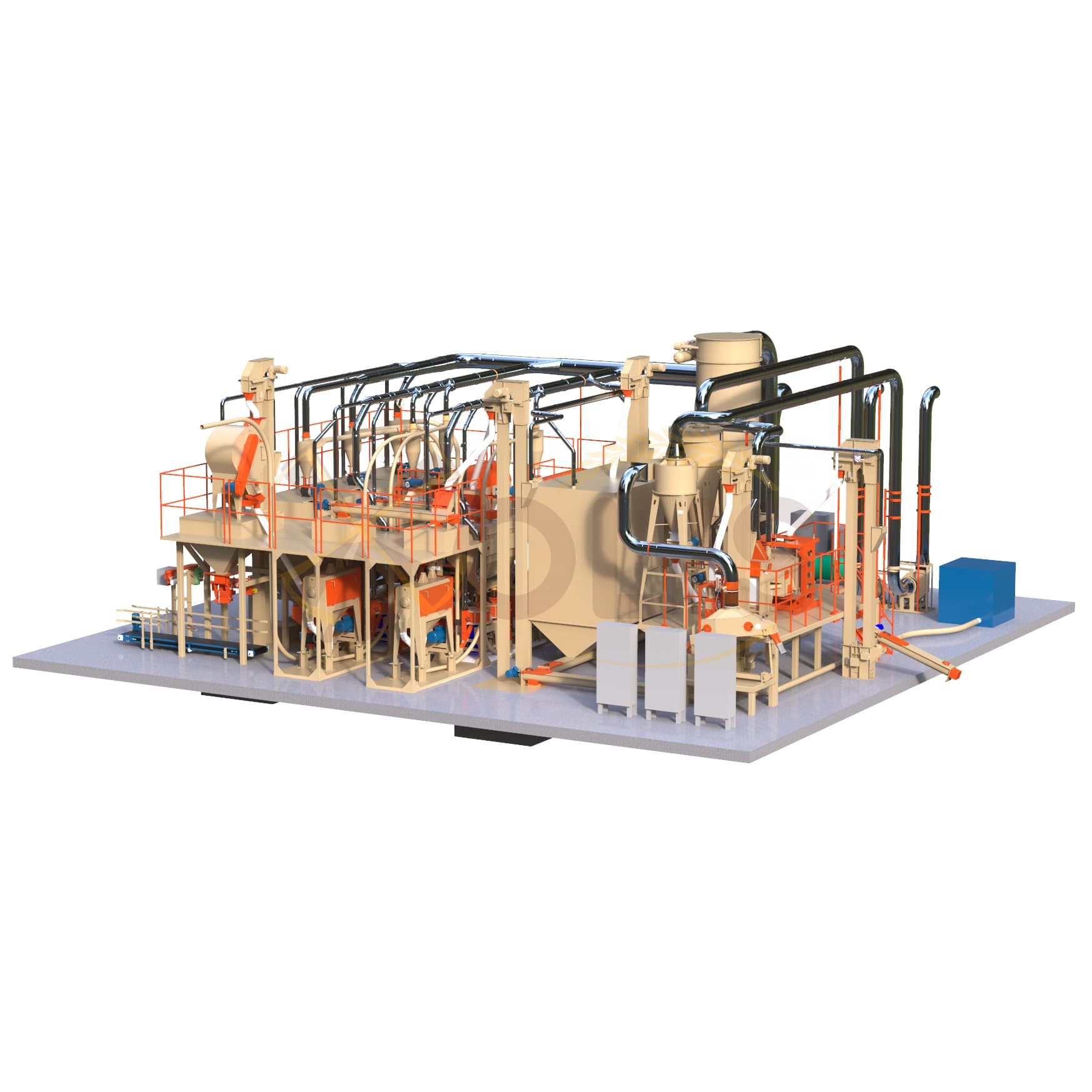

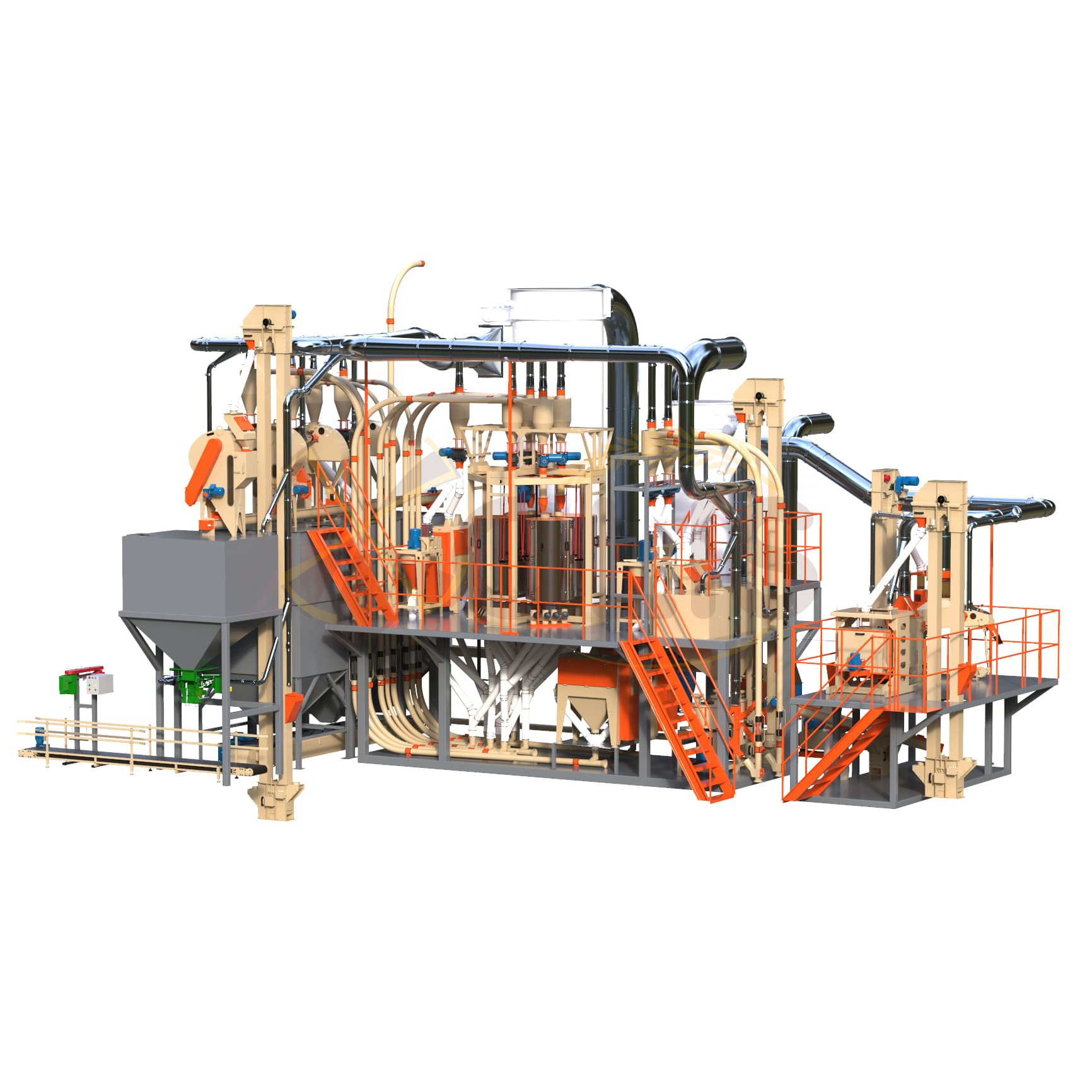

Aggregate multi-purpose groats mill (mini plant) OPTIMATIK-K-07

Purpose:

The OPTIMATIK-K-07 is a multipurpose groats mill, that has been designed for processing crops like wheat, barley, peas, corn, and millet into groats. The design and equipment of the groats plant ensure the yield and quality of groats are not lower than the requirements of the current standards, which allows to meet the requirements of the modern market.

The OPTIMATIK-K-07is a multipurpose groats mill that is supplied with a metal framework, ladder and service platform, hoppers, an aspiration system, a pneumatic conveying system, an electric part, and automatics. Since the manufacture of the groats mill passes the stage of the control assembly, its complete assembly and commissioning at the place of operation take no more than three days. In this case, the need for cutting, welding and drilling of metal at the place of assembly is completely eliminated.

The groats mill operates in automatic mode. The operator controls the operation of the groats mill from the central control panel.

Specifications

Assortment, output and productivity

*with partial germ removing;

*millet grade is determined by the class of processed millet

Voltage, 380W, 50Hz

3000

5450

Composition of grain manufactory:

Аdvantages

- The highest output and quality of groats in the class of small capacity multipurpose groats mill;

- Possibility of quick adjustment in case of changing the type of processed grain or the type of groats to be processed.

- The basic configuration can be supplemented with options, which significantly increase the possibilities of processing (additional cleaning, splitting of peas, grain enrichment, etc.).

- Compactness and low power consumption, which allows the operation of the groats mill in various adapted spaces.

- The operation of the groats mill is automatic.

- Reliability of the equipment of the groats mill ensures its uninterrupted and long-lasting operation.

- Efficient processing of low-grain cereals without reducing the quality of the groats;

- Assembly and commissioning of the groats mill within three days.

Video

Assortment, output and productivity

*with partial germ removing;

*millet grade is determined by the class of processed millet

Voltage, 380W, 50Hz

3000

5450

Composition of grain manufactory:

- The highest output and quality of groats in the class of small capacity multipurpose groats mill;

- Possibility of quick adjustment in case of changing the type of processed grain or the type of groats to be processed.

- The basic configuration can be supplemented with options, which significantly increase the possibilities of processing (additional cleaning, splitting of peas, grain enrichment, etc.).

- Compactness and low power consumption, which allows the operation of the groats mill in various adapted spaces.

- The operation of the groats mill is automatic.

- Reliability of the equipment of the groats mill ensures its uninterrupted and long-lasting operation.

- Efficient processing of low-grain cereals without reducing the quality of the groats;

- Assembly and commissioning of the groats mill within three days.