Mill high-quality grinding wheat productivity of 60 tons/day

Purpose:

The complete milling plant with a capacity of 60 tons/day is designed for processing wheat grain into graded flour to obtain flour of the highest, first and second grades. The mill realizes short structure milling and solves the problem of flour supply for bakeries, confectionery and pasta production at the regional level.

Description:

The mill requires a 4-storey building with a floor height of at least 3 meters and an area of each floor of at least 180 m2. In case of absence of a suitable building, it is recommended to make the supporting metal structure for equipment placement in the form of a four-level frame up to 10 m high with dimensions of 12 m x 15 m in plan and to install it on its own foundations. In this case, it is advisable to install the external enclosures (walls and roof) on reinforced concrete structures and foundations independent from the steel structure carrying the equipment. The estimated height of the building is 12 meters. The construction part can be supplemented with rooms for operator’s room, workshop laboratory, warehouses, etc.

The mill works in automatic mode. The mill is controlled by the operator from the central control panel.

Within the framework of individual project execution, such communications as:

– A line for grain acceptance from vehicles and its preliminary cleaning;

– Warehouse for placement and storage of operational grain stock with a line for formation of milling batches and their supply to the production building;

– Weighing and sampling department with the possibility of sampling both into bags and small containers;

– Bulk storage and bran granulation warehouse with a line for unloading into trucks;

– Bulk storage warehouse for flour with a line for shipment into trucks.

Specifications

Basic yield of flour depending on realized grinding

(from grain basic conditions)*:

3 phase alternative currency

voltage, V

frequency, Hz

50

The composition of the mill to offices, lines, machines and parts.

Аdvantages

- The highest yield and quality of flour in the class of low-capacity mills.

- Efficient processing of grain of low milling conditions without reducing the quality of flour.

- Stable quality of milling in the cold season, which is ensured by the presence of a grain heater.

- The quality and quantity of gluten in flour, as well as their stability, are ensured by the presence of communications for the formation of milling batches of grain.

- Quick change of the type of milling and the yield of flour by grade is ensured by the presence of collection screws for finished products.

- It is possible to select semolina, flour and edible bran included in the recipe for a number of bread varieties.

- It is best suited for re-equipping existing low-capacity mills of various periods of construction.

- The milling plant operates automatically.

- The reliability of the milling plant equipment ensures its uninterrupted operation over a long period of operation.

- The mill can be reconfigured for wholemeal grinding of rye, as well as the production of flour from whole grain.

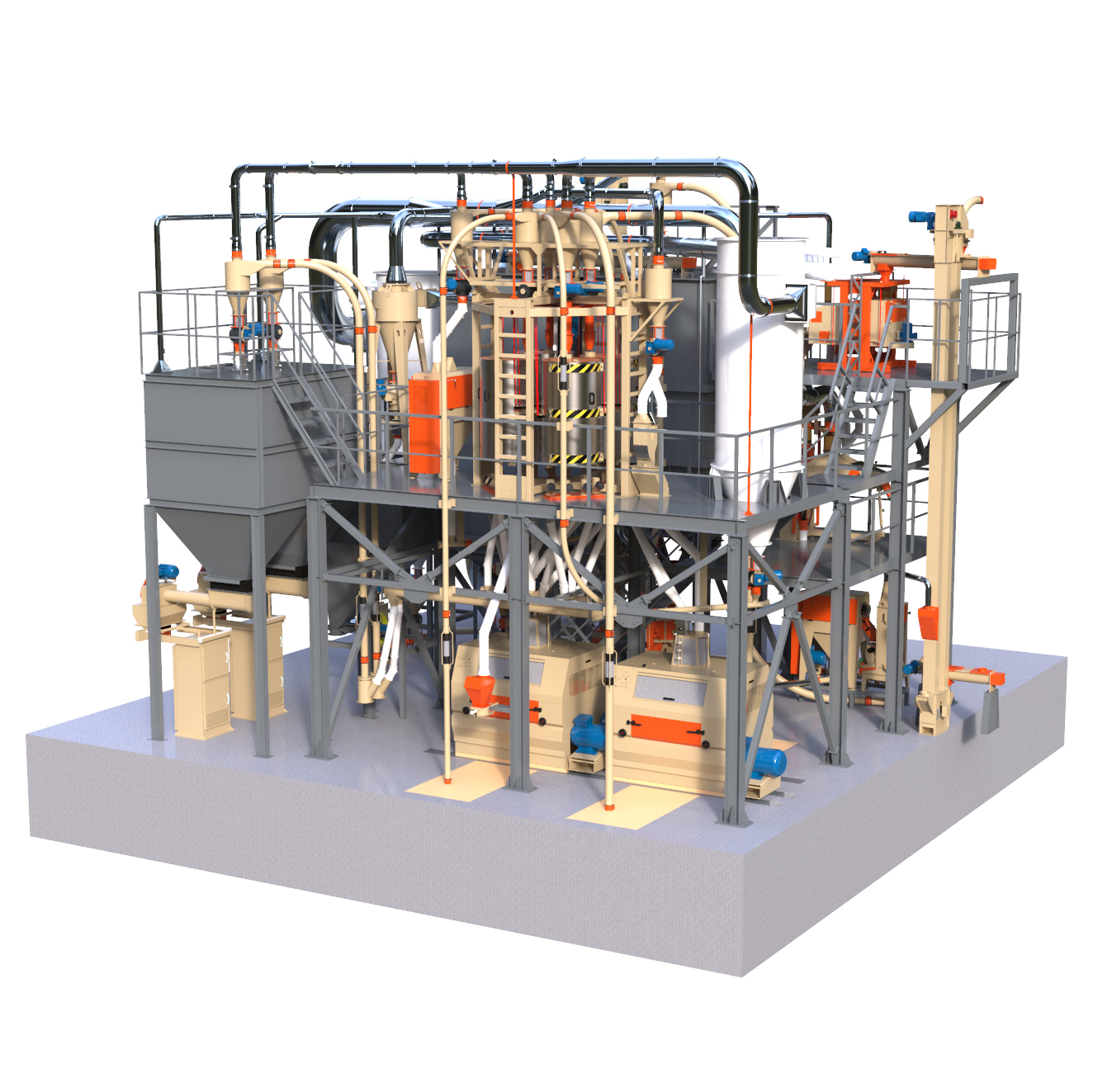

Photo

Basic yield of flour depending on realized grinding

(from grain basic conditions)*:

3 phase alternative currency

voltage, V

frequency, Hz

50

The composition of the mill to offices, lines, machines and parts.

- The highest yield and quality of flour in the class of low-capacity mills.

- Efficient processing of grain of low milling conditions without reducing the quality of flour.

- Stable quality of milling in the cold season, which is ensured by the presence of a grain heater.

- The quality and quantity of gluten in flour, as well as their stability, are ensured by the presence of communications for the formation of milling batches of grain.

- Quick change of the type of milling and the yield of flour by grade is ensured by the presence of collection screws for finished products.

- It is possible to select semolina, flour and edible bran included in the recipe for a number of bread varieties.

- It is best suited for re-equipping existing low-capacity mills of various periods of construction.

- The milling plant operates automatically.

- The reliability of the milling plant equipment ensures its uninterrupted operation over a long period of operation.

- The mill can be reconfigured for wholemeal grinding of rye, as well as the production of flour from whole grain.