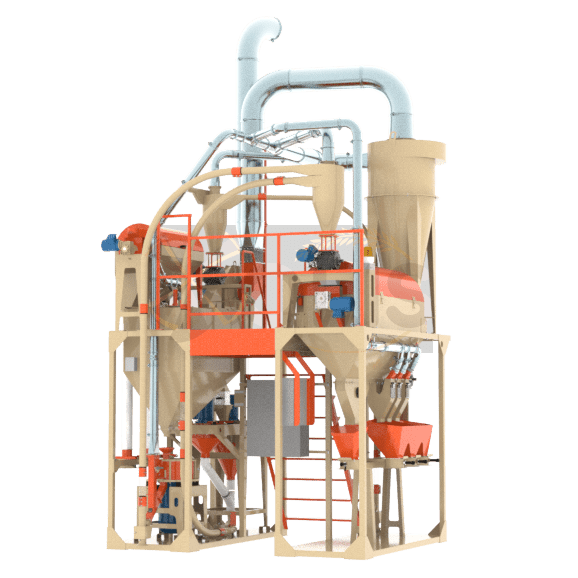

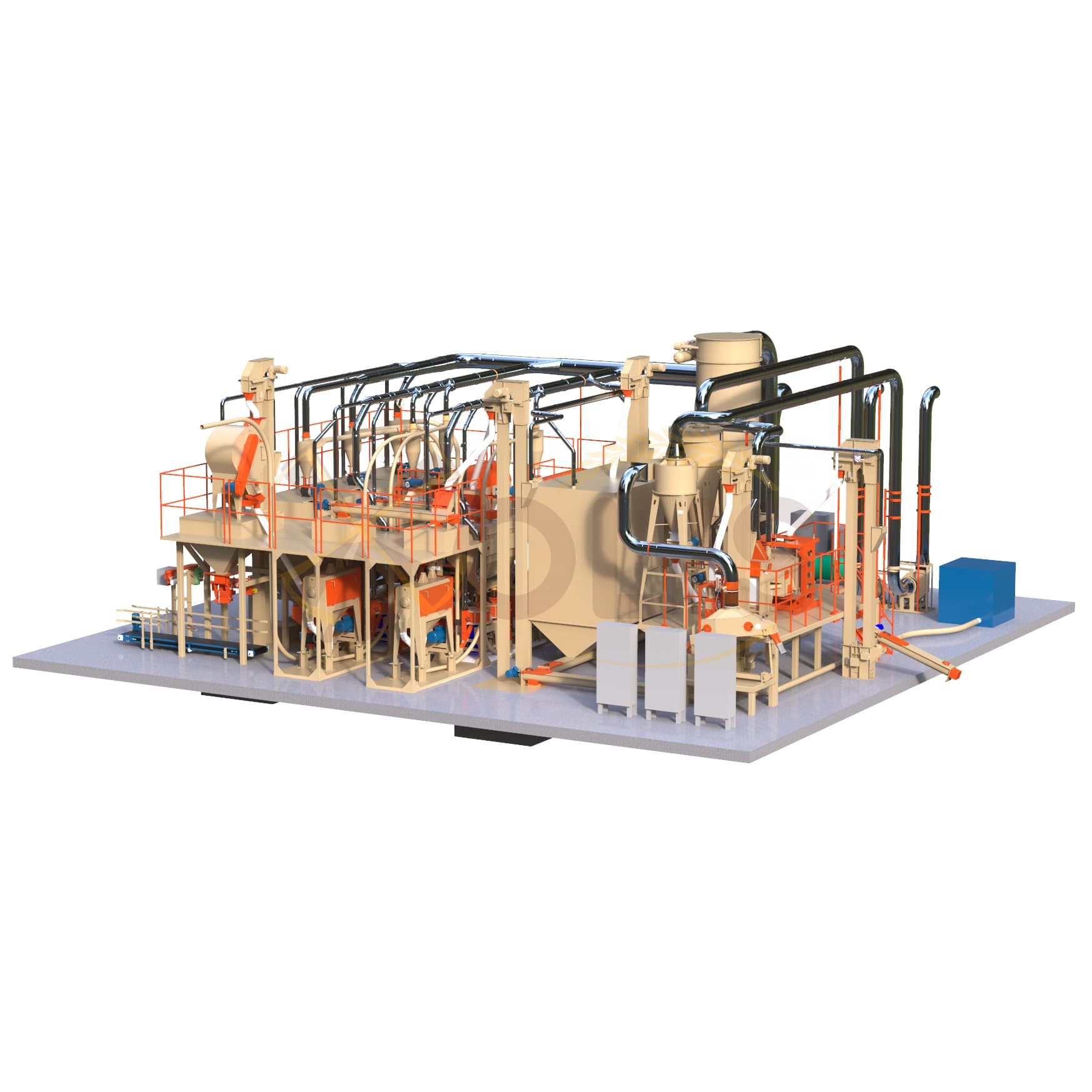

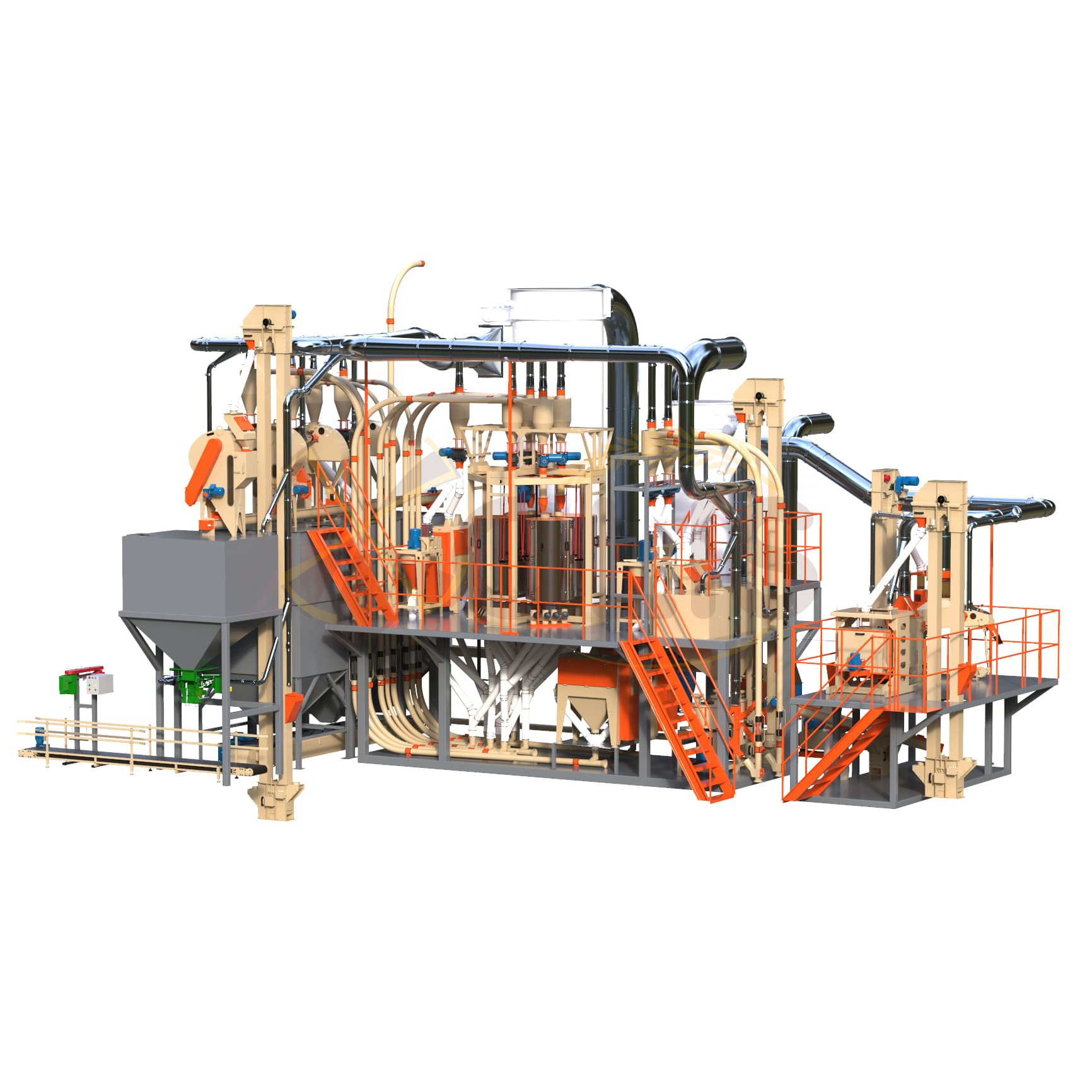

Aggregate unit for groats enrichment UOK-1

Purpose

Aggregate unit for groats enrichment UOK-1 is designed for purification of grain products from impurities which are difficult to separate. The UOK-1 can be used for processing of millet to increase its grade, corn groats to separate particles of germ and shell, as well as grains of small-seeded crops to reduce their clogging.

Enrichment of graots and other cereal products in UKO-1 is realized by vibration-pneumatic separation by pneumatic sorting table of SPS .

The aggregate unit for groats enrichment UOK-1 is supplied with metal framework, ladder and service platform, hoppers, aspiration system, pneumatic conveying system, electrical part and automatics. Since the UOK-1 undergoes the control assembly stage during production, its complete assembly and commissioning at the place of operation takes no more than two days. The need for cutting, welding and drilling of metal at the place of assembly is completely eliminated. Aggregate unit for for groats enrichment UOK-1 can be easily integrated with aggregate multipurpose groats mill “OPTIMATIK” into the unified transport and technological complex.

The UOK-1 operates in automatic mode. Its operation is controlled by an operator from the central control panel. In case of operation of the UOK-1 with the multipurpose groats mill “OPTIMATIK”, their operation is ensured by the same operator

Characteristics

Voltage, 380W, 50Hz

width

length

height

6900

5940

Equipment composition of the UOK 1

Аdvantages

- Improves the quality (consumer properties, appearance and composition) of produced groats and other cereal products.

- Allows the processing of low-grade grains without compromising the quality of the groats.

- The possibility of quick adjustment in case of changing the type of groats or the type of grain to be processed.

- Compactness and low power consumption, which enables operation of the machine in various adapted rooms.

- Operation is performed automatically.

- Reliability of the grain mill equipment ensures trouble-free and long-lasting operation of the processing unit.

- It can be easily integrated with the multipurpose groats mill “OPTIMATIK-K”.

- The unit is assembled and up and running within two days.

Video

Characteristics

Voltage, 380W, 50Hz

width

length

height

6900

5940

Equipment composition of the UOK 1

- Improves the quality (consumer properties, appearance and composition) of produced groats and other cereal products.

- Allows the processing of low-grade grains without compromising the quality of the groats.

- The possibility of quick adjustment in case of changing the type of groats or the type of grain to be processed.

- Compactness and low power consumption, which enables operation of the machine in various adapted rooms.

- Operation is performed automatically.

- Reliability of the grain mill equipment ensures trouble-free and long-lasting operation of the processing unit.

- It can be easily integrated with the multipurpose groats mill “OPTIMATIK-K”.

- The unit is assembled and up and running within two days.