Vereshchinsky A.P. – Doctor of Technical Sciences, General Director of “Olis” LLC, Odessa;

Shevchenko A.V. – Head of Development and Implementation Department of “Olis” LLC, Odessa

It is well known that millet, produced according to traditional technology, is a millet grain, completely free from floral and partially from seed and fruit hulls, aleurone layer and germ. The floral hulls of millet are tough, more than half fibre and therefore must be completely removed. The germ and aleurone layer of millet contain dark and unstable fat, so these components together with the seed and fruit coats are mostly removed by grinding. The ground millet acquires a bright colour and a notch in the place where the germ was located. The basic yield norms of millet processing provide for obtaining 11.5 per cent of fodder products, which are crushed and flour formed by kernel particles as a result of its husking and grinding. Nevertheless, the shelf life of millet is one of the lowest among bakery products and is 6 months.

At the same time, the fruit and seed hulls of millet, comprising 3-5% of the grain weight, are a source of valuable trace elements (phosphorus, magnesium, zinc, copper, iodine, etc.). The germ, constituting 4-6% of the grain weight, and the aleurone layer are rich in vitamins B1, B2, PP and folic acid. Thus, by preserving these anatomical parts in the composition of groats, it is possible not only to significantly increase its yield, but also to obtain a valuable unrefined product for organic nutrition. In this case, the complete liberation of the kernel from the floral shells with minimal damage to the surface and especially the germ should provide decent consumer properties and marketable appearance of the groats, as well as long shelf life. However, to achieve this goal, i.e. to obtain millet-dranz as a final product of processing for food needs, it is necessary to solve the problem of complete removal of floral shells of millet grain without the use of grinding operation, and the peeling processes should be carried out with minimal trauma to the kernel.

Our studies [2] have established that gentle modes of millet husking are effectively realised by using roller huskers with the working surface of rollers made by modern wear-resistant polymeric materials. Application of two systems of husking, realised by means of roller huskers, provides grain husking coefficient about 93% without its preliminary fractionation. At the same time, the appropriate value of the peeling ratio of the first system is about 70 %. Due to the insignificant increase of husked grains the use of subsequent husking systems is recognised as inexpedient. Further complete removal of floral shells is provided by grinding operation performed in peeling and grinding machines with abrasive rotor.

Solving the problem posed in the present work required the development of a method to completely free all millet grains from floral shells without the use of grinding operations. As a result of search researches it has been established that separation of husked and not husked grains with high clarity can be carried out on sorting systems. A prerequisite for ensuring such separation is the calibration of millet grain into 4-5 fractions followed by husking and sorting of each fraction. During sieving, sieves with round holes are used, with the sorting sieves for each of the fractions being set one number lower than the calibration sieve from which the given fraction is obtained.

Table 1 shows the results of calibration of two different samples of millet of class 1, ІІІ type – sample 1 and ІІІ type – sample 2. From the given data it is clear that different millet batches require individual selection of sieves for this operation. However, in both samples the passage of the sieve Ø2,1 is represented by flower shells, small collapsed grains, sharps, etc., which should be sent to waste during further processing.

Table 1. Results of calibration of millet grain

| Sample 1 Fraction yield, % |

Sample 2 Fraction yield, % |

|

| Outflow Ø2,5 | 12.5 | 1,6 |

| Outflow Ø2,4 | 43.1 | 6.5 |

| Outflow Ø2,3 | 24.4 | 40.5 |

| Outflow Ø2,2 | 11.5 | 24,1 |

| Outflow Ø2,1 | 7.3 | 25.9 |

| Pass Ø2,1 | 1,2 | 1,4 |

| Total | 100 | 100 |

Results of peeling of the most representative fractions of millet samples 1 and 2, performed sequentially on three systems, are presented in Table 2. As can be seen, peeling of calibrated grain of millet is characterised by high efficiency. Thus the yield of millet-dranz after the third system of peeling was 78.9% and 81.1%, respectively. Moreover, in millet obtained from sample 1, broken kernels – up to 1%. No broken kernels were found in the millet obtained from sample No. 2.

Table 2.Results of husking of millet grain

| The peel system | Sample 1 Pr. Ø2,5, scheme. Ø2,4 Peel coefficient, % |

Sample 2 Pr. Ø2,4, schem. Ø2,3 Peel coefficient,% |

| No. 1 | 95.6 | 96.3 |

| No. 2 | 98.4 | 98.7 |

| No. 3 | 99.4 | 99.7 |

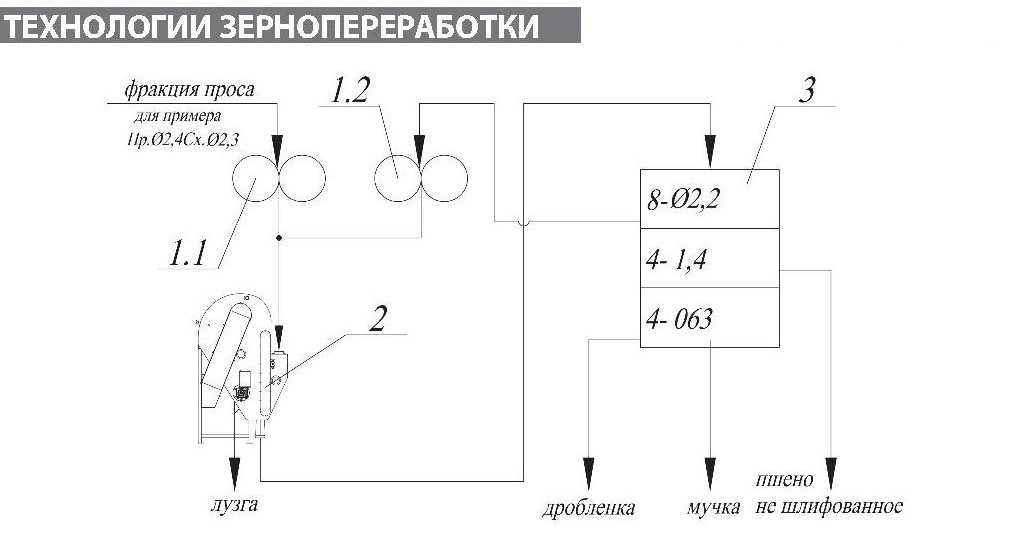

In view of the conducted searches the technological scheme of the rushal process of production of millet-dranz was developed (Fig. 1 ). Results of bench tests have confirmed expediency of the second peeling system, in spite of its low loading. Ensuring the absence of unflaked grains in the groats requires a more “rigid” mode of processing of the convergent fraction of the sorting system.

Fig.1. Principal technological scheme of the roughening process of production of ungrinded millet:

1- roller peeler; 2 – aspirator; 3 – sieving section

Processing of cleaned millet grain by the new technology provides a yield of millet-dranz up to 80%. Along with the maximum use of grain potential for food purposes such technology allows to produce groats with a complete absence of grains containing floral shell (Fig. 2), without resorting to the use of optical sorters. The above results allow us to recommend the developed technology for the production of a new organic type of cereal – unground millet, or millet-dranets.

Figure 2.Products of millet processing: unground millet and husk

LITERATURE

- Kroshko G.D. Rules of organisation and conduct of technological process at large’yanichnyh plants. [Text]/G.D. Kroshko [and іn]. – K.: “Vipol”, 1998.- 145 p.

- Greenberg E.N. Production of groats [Text]/E. N. Grinberg. -M.: “Agropromizdat”, 1986. – P.89-92.

Published by

“Grain storage and processing”

Scientific and Practical Journal

No. 1 (198) January 2016