Vereshchinsky A.P., PhD, General Director (OLIS LLC, Odessa);

Yanyuk T.I., Candidate of Technical Sciences, Associate Professor (NUPT, Kiev);

Pyrus Y.B., Director on developments and implementations (LLC “OLIS”, Odessa).

Oat grain products are known to occupy an increasing part of the human diet. Oats are used for manufacture of various flakes, toloknoi and flour. High nutritional and biological value of these products is in demand in children’s, dietary and geriatric nutrition.

The basis for the production of food products from oat grain is oat groats, the technology of obtaining which is well enough substantiated by science, covered in the literature and implemented at many enterprises. Despite this, in modern practice of oat processing there are certain difficulties due to the special structure of the grain of this crop, as well as new requirements in the changed conditions of economic management of processing enterprises.

Anatomical feature of oat grain is that under its floral shells there are short pubescence hairs (down) covering the entire surface of the kernel. Their content reaches 1.5…2.0 % of the grain weight. The presence of pubescence hairs in the peeling products leads to sticking of down on the working bodies and internal surfaces of the equipment, reducing the efficiency of its work, which requires periodic emergency stops for cleaning. When getting into the finished product pubescence hairs deteriorate its consumer properties and appearance. Traditional technologies of oat processing assume separation of pubescence hairs in a mixture with husk by means of ostelomators and aspirators or only aspirators, but with subsequent grinding of groats in machines with abrasive working surfaces. Due to the high fibre content the obtained product (husk) has a low feed value and as a feed component with a number of restrictions can be used only for cattle. In modern conditions of management such use of husk is deprived of expediency. At the same time, the processing of oats into food products is associated with the need to use a significant amount of heat energy, in particular, to obtain steam. The available experience of processing enterprises confirms the economic feasibility of using oat husk as a solid fuel for these purposes. However, as our observations show, combustion of husks containing pubescence hairs causes low efficiency of fuel utilisation and increased emission of harmful substances into the atmosphere. Under such conditions, the task of selecting pubescence hairs in the purest possible form and searching for the direction of their rational use becomes urgent.

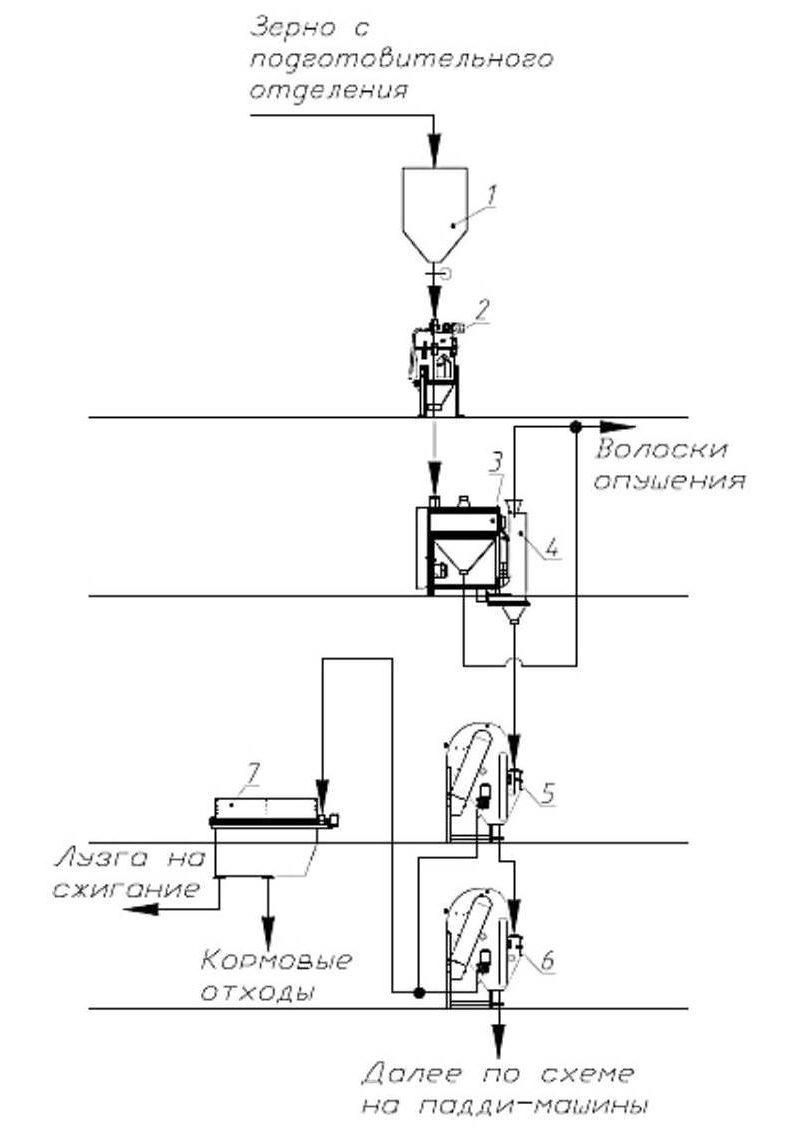

As a result of studies of processing modes of oat husking products, we have developed a fluff separator of MVP brand (Fig. 1), as well as the corresponding technological scheme (Fig. 2), which allowed to provide separate separation of pubescence hairs (together with a small number of small particles of flower coat) and husk (almost completely devoid of fluff). At the same time, as a result of the fluff separator operation, some increase in the content of broken grains was observed in proportion to the increase in the grain peeling coefficient. However, there were no quantitative changes in the groat yield.

Fig. 2 Technological scheme of the stage of husking of oat grain:

1 – hopper; 2 – centrifugal peeling machine Shtso-1;

3 – fluff separator МВО-3’0-01; 4 – pneumatic separating channel VSO-4OO;

5 – aspirator ACC-5,0; 6 – aspirator ACC-2,5; 7 – sifter BM-1’2.

Analysis of the chemical composition of the isolated down (Table 1) explains the problems existing in the burning of husk with its content, and also shows’ that the above product is a significant source of nutrients and can be used in the feed industry as a valuable raw material.

Table 1. Chemical composition of oat pubescence hairs.

| Name | Number % |

| White | 7 |

| Fibre | 18 – 19 |

| Fat | 2,3 |

| Starch | 25 – 27 |

| Sugar | 2.5 |