Practice of innovations in croup production technology.

Shevchenko A.V., Head of Development and Implementation Department of “OLIS”

When considering innovations in cereal production technologies, optical sorters should be mentioned first of all. (Slide 1) This is undoubtedly a new, very advanced and intensively developing technology, on the one hand. On the other hand, there is already experience in the operation of such machines in industry, which allows us to define the framework of their effective use. The optical sorter is a machine that uses mainly colour differences as a separability feature and is thus valuable in that none of the traditional machines use this feature. However, when selecting a separating machine, it is important to realise how well the separating feature used by the machine matches the purpose of the separation. Nevertheless, a common mistake in the use of optical sorters is to separate by colour what is not separable by colour, but which is separable by traditional separating machines with high efficiency. Therefore, the framework for the effective operation of optical sorters, in view of their high cost, is not a replacement of traditional separation operations, but a complement to them. Based on the accumulated experience in the majority of production technologies traditional for our country – croup – are the final operations to finalise the quality of individual batches of finished products.

In the following, I would like to offer you a brief overview of innovations that have recently been applied in cereal production practice.

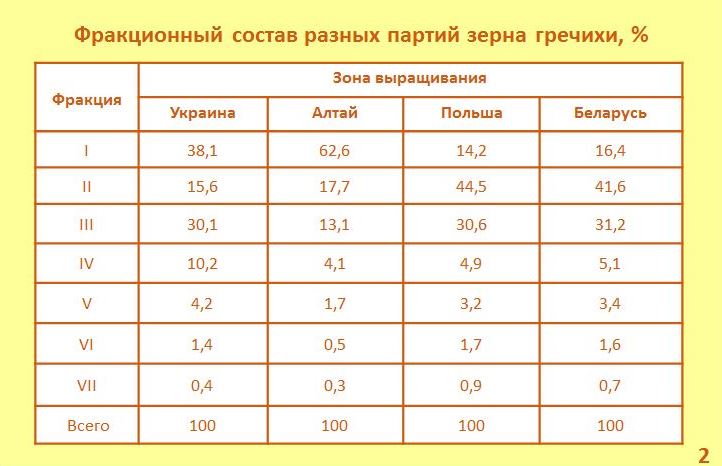

Wheat processing technology. One of the most important components of buckwheat processing success is the efficiency of the grain calibration operation, which in turn determines the efficiency of husking, separation of uncut grains on sorting systems and their content in the finished groats. In addition, all these operations have a direct impact not only on the quality, but also on the yield of groats. In accordance with the “Rules of organisation and conduct of technological process” the recommended values of undershoots depending on grain size fractions are in the range from three to six percent. Our research has shown that the increase in quality and yield of kernel groats is primarily associated with a significant increase in these indicators. The analysis of buckwheat grain batches grown in Ukraine, Russia, Kazakhstan, Poland, Belarus and Baltic countries shows a wide range of variation in grain size and percentage of its individual fractions (Slide 2). The analysis confirmed the feasibility of buckwheat grain fractionation into six fractions, and in some cases even into seven fractions. Material balances of processing batches of grain of different fractional composition showed structural contradictions of the traditional organisation of the production process, implemented within the framework of the adopted modes and technological schemes of sieves BRU. Elimination of the revealed contradictions required the development of new processing modes and nine original technological schemes of sieving, allowing efficient production of buckwheat groats in all studied zones of raw material growth. Thus, the improved technology of the rushing stage together with rational modes of the TRP stage allow to achieve the yield of buckwheat groats 72-74% at processing of conditioned grain, which is 10-12% higher than the basic norm of yield.

Oat processing

With regard to oat processing, we would like to touch on two aspects. Traditionally, the separation of oat husking products into kernel and unhusked grains is nowadays carried out in paddy machines. The clarity of this separation determines the quality of the groats in terms of the content of uncut grains and oat flakes in terms of the content of floral films. Often the efficiency of this operation is ensured by reducing the productivity of the whole groat mill, being a “bottleneck”. However, before the widespread use of paddy machines, the separation of oat husking products in domestic processing was carried out on oat triers. The clarity of division in the trier is much lower than in the paddy-machine, so in addition to the main trier system in the processing scheme included a control trier. In spite of this, the triers still conceded this operation to paddy machines. However, unlike paddy machines, triers do not produce dynamic loads, are smaller in size and much cheaper, which makes it possible to use them as a pre-sorter. (Slide 3) Industrial testing of the method of separation of oat husking products with the use of trier and paddy-machine showed its efficiency. By ensuring the content of uncut grains in the kernel to zero whole four tenths per cent allows to increase the productivity of the separation operation by twenty to thirty per cent.

An anatomical peculiarity of oat grain is that under its floral sheaths there are pubescence hairs (down) covering the entire surface of the kernel. Their content reaches 1.5…2.0 % of the grain weight.

Analysis of the chemical composition of the isolated down (Slide 4) explains the problems existing in the burning of husks with its content, and also shows that this product is a significant source of nutrients and can be used in the feed industry as a valuable raw material. Therefore it is necessary to extract pubescence hairs not only from the oat kernel, but also from the husk. For this purpose, our company includes a specially designed machine in the oat processing scheme.

Maize processing

As is known, two fundamentally different technologies are used in corn groats production today – traditional and relatively new. (Slide 5) The traditional technology involves the primary grinding of grain in percussion dehumidifiers and germ separation on pneumatic tables. The new technology is realised through the use of percussive action dehumidifiers, where as a result of force the germ is crushed and through the sieve shell is removed from the processing process, i.e. it can be used in the crushed form only for fodder purposes.

Thus, in the new technology operations of embryo separation on pneumatic tables are not applied. However, depending on the variety, growing conditions and post-harvest processing, batches of maize grain have different content of horny and powdery layer in the endosperm. At processing according to the new technology the floury layer of endosperm, due to its low strength, is crushed together with the germ and is sent to waste, i.e. cannot be used for food purposes. Therefore, the new technology should be considered progressive and justified for processing maize with a significant content of horny endosperm and provided that there is no purpose in obtaining the germ as a separate product. In spite of considerable energy consumption in abrasive dehairminators, which is about 10.0 kW per tonne of grain, such production facilities are compact and it is justified to implement them, provided that the raw material is of the required quality. For processing of grain with a significant content of floury layer, namely such grain is the basis of the domestic raw material base, preference should be given to the traditional technology. This technology allows the floury layer of endosperm to be partially included in the composition of groats and flour, as well as to preserve the germ, providing a higher yield of food products, and hence the economic efficiency of processing. In Ukraine, the majority of corn groats processing plants realise the traditional technology. However, the problem is that at the time of their creation this technology was not sufficiently substantiated, and many methods of its implementation existed at the level of assumptions. The results of the operation of such grits processing plants have formed a well-deserved opinion about the imperfection of the considered technology and the need for its improvement. Experimenting a lot in the field of cereal production technologies, our company has by now formed an idea of a rational technology of corn processing into groats and flour. The basis of such processing is:

- preliminary husking of the grain to reduce the impact of the initial milling, this increases the efficiency of groat formation and preserves the germ as a whole;

- Elimination of product spoilage in germ extraction systems on pneumatic tables, due to control systems;

- use of conditioning and grinding systems for enrichment of small products.

.

The listed innovations have been repeatedly tested in bench conditions and in production. However, mainly due to organisational reasons, such technology has not been implemented in full so far. Nevertheless, we are ready to create new production facilities and reconstruct the existing ones, which will ensure efficient processing of maize grain of any quality, including even effective control of black inclusions in groats, i.e. crushed gyre layer of the grain weevil.

As part of this report, I would also like to inform you about the positive results of the development and production testing of two new technologies. These are production of millet-drantz for food purposes and peas pounded not polished.

Millet processing

Millet, produced according to traditional technology, is a millet grain, completely free of floral hulls and almost completely free of seed and fruit hulls, aleurone layer and germ. However, the fruit and seed coats of millet are a source of valuable microelements (phosphorus, magnesium, zinc, copper, iodine, etc.), and the germ and aleurone layer are rich in vitamins B1, B2, PP and folic acid. Thus, by preserving these anatomical parts in the composition of groats, it is possible not only to significantly increase its yield, but also to obtain a valuable product for organic nutrition. At the same time, to ensure decent consumer properties and commercial appearance of groats, as well as long shelf life, it is necessary to ensure complete liberation of the kernel from the floral shells with minimal damage to its surface and especially the germ. (Slide 6) The developed by us technology, and also original park of machines for reception of millet-dranz, as the final product of processing for food needs, is realised without use of operations of grinding and allows to provide output of groats to 80 %. Together with maximum utilisation of millet grain potential for food purposes, this technology allows to obtain groats with almost complete absence of grains containing floral shell.

Pea processing

Analysis of the traditional technology of pea cereal production shows that the formation of a significant amount of flour and crushed peas during pea processing is due to the operations of peeling and grinding, realised by peeling and grinding machines. However, the study of morphology and anatomy of pea grain, as well as our search studies allowed us to justify the possibility of creating a technology for the production of chopped peas, realised without the use of peeling and grinding machines. (Slide 7) As a result, a machine for pea grain peeling and splitting it into seed pods was created, as well as developed a technological scheme for the production of peas, pounded not polished. Production approbation showed that the yield of cereals produced by the new technology is 3-4% higher than when using traditional technology, and the smooth glossy surface of grains without traces of damage gives the cereal, improved marketable appearance.

In conclusion, I would like to inform you that the company “OLIS” has a wide arsenal of effective technologies for the production of cereals, as well as all the necessary equipment for their implementation. Thanks to our constant research and development work we are constantly improving the capabilities of our technologies and equipment. Our Customers know that cereal factories created by “OLIS” company are profitable. Thank you for your attention.