Technological techniques for the selection of grains affected by Fusarium wilt from the grain mass

O.P. Vereshchynskyi, Ph.D., V.B. Ilchuk, Ph.D., E.A. Dmytruk, Ph.D., prof. , Yevtushenko O.O., Ph.D., Associate Professor, E.I. Kharchenko, Ph.D., Associate Professor

National University of Food Technology

Fungi of the genus Fusarium damage grain plants that have overwintered in the field, they cause the death of seedlings, rotting of the root system, darkening of leaves, sterility of ears and other defects, which is accompanied by deterioration of grain quality. Fusariosis of grain crops is one of the first diseases of grain crops in terms of harmfulness. The species composition of pathogens in different climatic zones may be different. Fusarium fungi are associated with the formation of skinny, light weight and poisonous grain. Fusarium grains are usually stunted and non-viable. In this case, the fusarium fungus penetrates the entire grain, which occurs as a result of deep impression of the seed during early infection of the ear in the field, in the milk phase and at the beginning of wax maturity. In the hidden form of fusarium infection, the mycelium of the fungus spreads in the outer layers of the grain, namely in the fruit and seed coat [2,3].

The poisonous fungus Fusarium is found in areas with high humidity. The intensive development of fusarium grain is facilitated by the combination of high air humidity and grain humidity above 17.0%.

Many species of fungi of the genus Fusarium are saprophytes. They can develop on grain after its harvest and during winter storage, so the fungus of infected grain can infect healthy grain in granaries. Most fusarium fungi in conditions of high humidity form a white-pink lush mycelium after 3…5 days. Infected grain is the most dangerous due to the presence of microorganisms in it. It is a source of infection of other grain during storage. With a strong degree of development of the fungus, the growing mycelium can cement the entire mass of grain into dense lumps. Grain harvested during rain or affected by a fungus cannot be mixed with healthy grain and should be stored separately [2,3].

An infected plant is distinguished by a white stem with a pink blurred pattern of the stems and its nodes. Affected ears or part of the ear turn white, while healthy parts remain green. Sometimes a solid pink coating forms on the spike. This infection is called Fusarium head blight [2].

Damage to the ear always leads to damage to the grain. On the grain, the disease manifests itself in the form of the following signs: a whitish, chalk-like surface, complete loss of gloss and glassiness, loose, fragile endosperm, wrinkling and thinness, a depressed, deep groove, the presence in it, or embryonic grains of spider web fungus, the embryo is non-viable and on the cut dark.

Pathogens hibernate on plant residues and in the soil. The main sources of plant infection are soil and plant residues. Infection of plants in the soil occurs at a temperature of 13…26 ˚C and a humidity of 40…80%.Insufficient soil moisture or its sharp fluctuations cause a stronger infection. The most optimal conditions for the development of mycelia and the formation of conidial sporulation on spikes and other above-ground parts of plants are an air temperature of 22…25 ˚C and a relative humidity of 70…80%. The mass development of Fusarium head blight occurs in years when there are frequent rains in the period from the beginning of earing to the ripening of the grain at an elevated temperature. There are no resistant varieties of grain crops to Fusarium fungi [2,3].

Mycotoxins produced by Fusarium fungi are the most widespread mycotoxins in the world. The interest of researchers in fusariotoxins has increased dramatically in recent years in connection with the emergence of new data on their toxic properties, as well as their ability in small amounts to disrupt the regulation of immunoglobulin production and act as carcinogens.

The pathogen Fusarium graminearum causes an acute disease called “drunken bread”. Getting inside the grain, fusarium mycelium forms a toxin – fusarin. The grain becomes poisonous, the flour from such grain is toxic, its consumption can cause severe septic angina, which is very dangerous for human health. Such grain can cause poisoning of animals [1].

The mushroom produces a specific metabolite – vomitoxin, which causes digestive and mental disorders in the body (weakness, agitation, tremors in the limbs). The content of vomitoxin in food wheat and grain for feed is normalized within 0.5 mg in 1 kg of grain. When milling common wheat, bran is the most contaminated with Fusarium wilt. They account for about 60% of the total amount of vomitoxin in grain. Separation, which is used at grain-receiving and grain-processing enterprises, allows removing 20…30% of the vomitoxin contained in the grain mass from Fusarium wheat. The processing of fusarium wheat makes it possible to bring the concentration of vomitoxin in grade flour and bread to the following limits: grain – 0.5 mg/kg, grain after cleaning – 0.38 mg/kg, flour of the highest grade – 0.35 mg/kg, flour of the 1st grade – 0.39 mg/kg, 2nd grade flour – 0.39 mg/kg, bran – 1.1 mg/kg, wheat bread – 0.3 mg/kg [3].

Placement, processing and temporary storage of grain is carried out in separate batches according to the degree of fusarium infection.In order to avoid the development of grain contamination and an increase in the content of vomitoxin during storage of wet and raw grain affected by fusarium, it is subject to immediate drying to a dry state and cleaning on grain cleaning machines in farms and bread-making enterprises.

In practice, grain infected with fusarium is mixed with batches of healthy grain. The amount of fusarium grain that is added to the normal grain is calculated depending on the degree of grain contamination in the infected batch. When feeding fusarium grain to animals, it is added in small quantities to healthy grain. Fusarium does not suppress the fermentation processes, so the grain infected with it can be used in the acetobutyl industry, in which wallpaper grinding flour is used as a raw material [3].

Measures to combat fusarium include the following: seed cleaning and pre-sowing treatment, timely harvesting, threshing and drying, seed treatment, agrotechnical measures [3].

The danger of fusarium grain necessitates the search for effective methods of its separation from healthy grain and technical means of implementation. For this purpose, relevant studies were conducted at the research and production base of OLYS LLC (Odesa). The SPS-3.5 pneumatic table was used to separate contaminated wheat with a grade of 796 g/l. Fusarium infection was 5.6%, separation productivity was 3998 kg/h. The results of the study are shown in table. 1.

Table 1

The results of the separation study on the SPS-3.5 pneumatic table of fusarium wheat grain

|

Pipe |

Productivity |

Nature, g/l |

Number of infected grains, % |

|

|

kg/h |

% |

|||

|

Source grain |

3998 |

100 |

796 |

5,6 |

|

1 room |

91 |

2,3 |

639 |

98.4 |

|

2 bedroom |

316 |

7.9 |

731 |

24.9 |

|

3x. |

697 |

17.4 |

773 |

7 |

|

4 rooms |

2150 |

53.8 |

804 |

0.4 |

|

5 rooms |

744 |

18.6 |

804 |

0.1 |

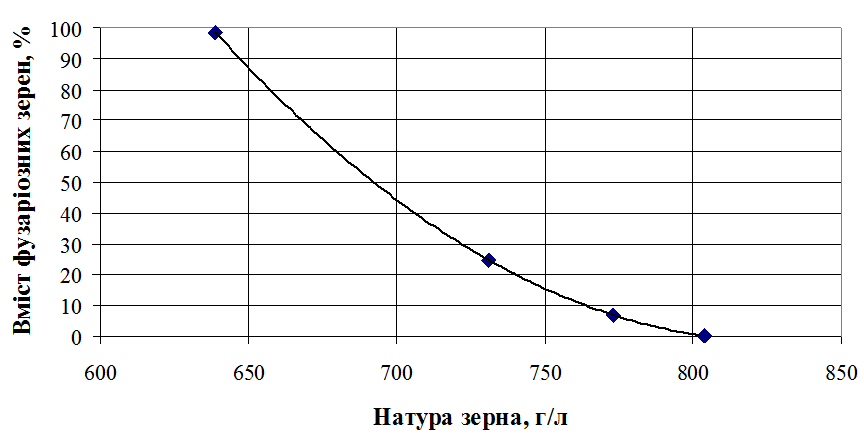

From the data in the table. 3, it can be seen that the largest number of grains infected with fusarium wilt (98.4%) is released by the first sprout. The nature of infected grain (639 g/l) is much lower than “healthy” grain (804 g/l). Considering that the causative agent of Fusarium wilt in the ear leads to the formation of underdeveloped, weak grains, the selection of the fraction with a low character and the highest content of infected grains is natural, because weak and incomplete grains, as a rule, have a low character. The use of the SPS-3.5 pneumatic table allows to separate 72.4% of grain with a fusarium grain content of 0.1…0.4%. In fig. 1 shows the dependence of the type of grain and the content of fusarium grains in the fraction of the corresponding type during separation in a pneumatic table.

Fig. 1. Dependence of the content of fusarium grains on the nature of the grain after separation in the SPS-3,5 pneumatic table.

The resulting dependence is approximated by the following equation:

where, B is the content of fusarium grains, %; γ is the nature of the grain, g/l.

For comparison, a study was conducted on the release of fusarium grains in the air separator AСО-0.5, in which light impurities and kernels that are completely affected by fusarium are isolated. Grains at the initial stage are not separated with this method of separation. With the help of air separator AСО-0.5, the efficiency of extracting fully fusarium grains of 80% was achieved with a separator productivity of 100 kg/h.None of the above methods of separation provides 100% cleaning of the grain mass from fusarium grains, but the use of pneumatic tables more effectively cleans infected fusarium grains from healthy ones.

Literature:

1. Ayzykovich, L.E. Physical and chemical foundations of flour production technology. – M.: Kolos, 1975. – 238 p.

2. Vereshchagin L.N. Pests and diseases of grain ear crops. – K.: Univest Marketing, 2001. – 128 p.

3. Kazakov E.D., Karpylenko H.P. Biochemistry of grain and bakery products. Ed. 3rd revision. and additional – St. Petersburg: GIORD, 2005. – 512 pp