Technical Director of LLC ‘OLIS’, Candidate of Technical Sciences A.P. Vereshchinsky.

The tasks of increasing the quality and yield of flour remain relevant for the majority of mills of wheat milling, which requires the search for guaranteed and economically justified ways of their solution. One of the directions of such search is the use of the process of grain treatment at the stages of its preparation for milling, known abroad under the term ‘debraning’. Debranning is a derivative of the word ‘bran’, which can be translated as husking, accordingly the machine for realisation of the husking process, i.e. the husker, is called ‘debraner’.

Removing the wheat shell and then grinding it is not a new idea and even, at first glance, not without logic. As it is known, in the process of husking, a considerable part of shells, dust particles, microorganisms are removed from the grain surface, and the grain mass itself is additionally cleaned of most of the impurities it contains. Thus, wheat grain should acquire higher milling characteristics, which, in turn, should have a favourable effect on the results of milling, especially for varieties.

At the same time, grain subjected to peeling differs greatly from the original grain in physical, mechanical, biochemical, physiological and other properties. Obviously, when peeling is used, most of the processes in the structure of milling go beyond the studied and traditionally applied regularities. Thus, the possibility of practical use of a simple, at first glance, idea requires the development of a new technology, and its hardware.

In the domestic flour-milling industry the most significant in this direction were the studies of I.T. Merko, I.R. Dudarev, conducted in OTIPP (Odessa), as well as the works of B.M. Maksimchuk, G.A. Egorov and other researchers, conducted in VNIIZ and MTIPP (Moscow). As a result, changes in grain properties in the process of wheat preparation for milling by peeling were studied, possible ways of realisation of the mentioned process were suggested, and also the positive effect obtained as a result of experimental milling was described.

There is information about the work in the considered direction abroad as well. Thus, for example, in the article ‘Ash content determination – a useful standard or a waste of time?’ researchers from Great Britain, the Netherlands and Australia reveal the mechanism of increasing the whiteness of flour obtained by removing the ‘top layer of bran’ before milling. It is noted that this treatment also improves the baking properties of flour, in particular its dough-forming ability.

A new technology of grain disinfection, recently offered by Bühler, involves cleaning the surface of wheat by peeling. It is noted in particular that this treatment results in flour with a higher whiteness index, a lower number of shell particles and an improved appearance.

Debranning as a new milling technology, machines for its realisation, its advantages and the positive effect obtained are also declared in PROKOP’s materials.

However, in such a huge and developed industry as domestic flour milling, there are no known cases of industrial application of the considered technological method by either domestic or foreign developers. According to our assumption, the reason for this is the lack of really tested technology and means of its implementation, allowing the effect of research milling guaranteed to turn into an economic effect at the industrial level.

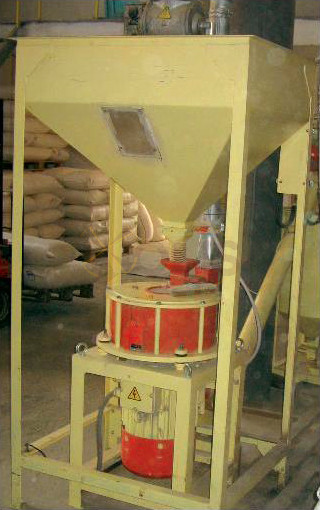

Nevertheless, having studied all available results of works related to debranning, we considered this direction to be quite promising in terms of practical use. As a result, since 2000 we started our own searches, researches and implementations. Already the first experiments confirmed that during preparation of grain for milling the processes of peeling are closely intertwined with the processes of conditioning. The husked grain absorbs moisture much more intensively and evenly with large increments of moisture. It is important to utilise this effect to reduce the time and improve the quality of conditioning. At the same time, it has been found that the effect of a significant increase in the whiteness of flour occurs when the shells are separated by more than 5 %, and in some cases 8 % and even 10 % of the grain weight. At such a degree of treatment, the germ, which plays an extremely positive role in conditioning processes, is inevitably injured, and the moistened grain becomes prone to caking. Thus, in view of the conditioning processes to be carried out, the surface has to be treated thoroughly, but in very gentle conditions. The MAO machine developed by us as a more efficient analogue of the existing rinsing machines (Photo 1) is best suited for this task.

The essence of the design and peculiarities of its operation are detailed in the article ‘Grain surface treatment at mills’, magazine ‘Storage and Processing’ No. 5, 2005. As a result of interactions with the working bodies, in this machine there is a separation of shells in the amount of 1.5-2.0 % of the grain weight. This leads to the reduction of its ash content by 0,05-0,08 %, increase of natura by 15-20 g/l and reduction of weed impurity content by 30-40 %. The given data show that the MAO machine is really much more efficient than traditionally used rinsing machines of A1-BGO and A1-BMO types. At the same time, the grain is practically not traumatised and its surface acquires a rough surface. For uniform moistening of such grain there is no need for intensive moistening machines of A1-BSM type, which are energy-intensive and also traumatise both the grain itself and its germ. Sufficiently effective moistening can be organised by spraying water even in an ordinary screw conveyor several metres long, providing, if necessary, reliable moisture increment up to 5-6 %. At the same time, by increasing the rate of moisture absorption, the time of dehulling can be reduced by 30 %, which is especially important when processing dry, glassy grain.

Our observations have shown that it is most expedient to remove shells in significant quantities before the last stage of conditioning, providing two, and for dry and vitreous grain – three stages in the case of cold conditioning method. Attempts to use for this purpose the peeling and peeling-grinding machines known in the industry, including various modifications of A1-ZShN, proved to be unsuccessful. At the same time, the accumulated experience allowed us to formulate the main requirements to the necessary machine. Such a machine should provide high degrees of peeling and evenness of processing without the formation of bare endosperm sections. The peeling process should be carried out with low energy consumption and be stable on grain with moisture up to 17 %. In addition, the machine should be easy to control and adjust to any peeling coefficients from the required limits, be reliable and integrated into the mill’s automated control system. These requirements are met by our machine design called ‘Cascade’ and its range of four models with different capacities. Approaches to the creation of this machine, its design features and the provided effect are given in detail in the article: ‘New machines for highly efficient grain surface treatment’, magazine ‘Storage and Processing’ No. 5, 2002. In the case of wheat husking, as part of its preparation for milling, treatment in the ‘Cascade’ reliably provides a reduction in grain ash content by 0.2-0.3 %, which is an order of magnitude higher than in traditional grain preparation lines, equipped with shearing, washing machines or wet husking machines. Analysis of the separated bran for ash content showed that at the required degree of peeling the value of their ash content approximately corresponds to the ash content of bran of the milling department. This indicates that the separation of a significant part of the bran in machines ‘Cascade’ before milling grain does not entail losses of flour, affecting its yield. The same conclusion is reached by the results of starch content analyses. When processing in the Cascade machines, a further reduction in the content of weed impurities and an increase in grain naturality are observed. Electricity consumption for processing depending on the degree of husking is 9 – 15 kW/t. In the process of husking the grain is heated to a temperature of 30-35 degrees, its humidity decreases by 0.3-0.7 %, mainly due to drying of the shells. Such reduction of grain moisture content should be compensated at the last stage of conditioning. Freed from shells, warm grain both intensively dries out and, in case of moistening, absorbs moisture. The thawing processes accelerate, acquiring the characteristics of hot conditioning with the strengthening of weak gluten. At this stage, the mill technologist has a real opportunity to correct errors and mistakes made in the previous conditioning stages. Correctly using the effect of heat and mass transfer during grain flaking, its moistening, interactions with aspiration air and transport communications it is possible within the framework of the last stage of conditioning to dry the grain by up to 1 % and to moisten it by up to 2 % with distribution of the added moisture on the surface or deep into the grain.

When milling the grain prepared in the above described way, the character of groat formation in the dredging process changes. Much less energy is required to grind the grain, which fully compensates for the energy expenditure in flaking. This is clearly confirmed by the fact that the service life of the rolls before the next cutting increases by 1.5-1.7 times. In the husked grain the integrity of the shells and their connection with the endosperm is broken, therefore, more groats and dung products are formed, they are finer, but of better quality. Even at high milling regimes, groat formation is mainly limited to the first two systems. Given that the shell content of the grain is low and the bonds with the endosperm are weakened, a single roller system is sufficient for shell milling in most cases. In some cases, a system equipped with a milling machine or even an entolator can be used instead of a roller system with satisfactory efficiency. The parameters of the rolls in the dredging process are recommended to be conventional. However, practice has shown that, taking into account the nature of the products to be ground, it is desirable to reduce the number of riffles by one on all systems. According to our observations, at that quantity and quality of groat and dung products, which is provided by the above described technological fragments, the use of enrichment processes on sieve machines is not a determining factor for obtaining high quality and yield of flour.

In the milling process, the grinding of groat and dunnage products does not have any distinctive features. However, in most cases, it is possible to reduce the milling process by one system, which is explained by the arrival of smaller products from the dredging process, presumably with a greater development of micro-cracks. In the cases where cut rollers and/or entolayers are used to ensure high recoveries on the milling system products, no significant deterioration in flour quality has been observed. Guaranteed high recoveries (60-70 % on ‘head’ milling systems) are ensured by the Simpaktor entolayers we use. The use of entolayers of this design is an additional argument in making decisions on reducing the number (length) of roller systems.

Technological fragments, the main features of which, trends and means of realisation are given above, have been combined by us into a technology allowing industrial implementation. The use of such technology in different mills has its own peculiarities. Thus, for application at small capacity mills, such as R6-AVM, MVS, as well as some models of ‘Kharkovchanka’ we have developed compact standard units, including ‘Cascade’ machine of required capacity with a set of necessary technological, transport and other elements (Photo 2). Such installations are aggregated with corresponding brands of mills and use for work the reserve part of air of their regular pneumatic conveying. In a number of cases the introduction of debranning requires some changes in the technological features of the grinding compartments of these mills.

Quite widespread and demanded recently are mills with productivity of 40-60 tonnes per day. As a rule, they are imported aggregate mills or mills of domestic construction, created according to individual projects. A distinctive feature of these mills is a reduced grinding structure realised on the basis of industrial equipment. However, the majority of such mills do not withstand professional criticism in terms of compliance with the basics of grinding technology, design, construction and other solutions. Implementation of debranching in the mills of the described type is usually carried out as part of their reconstruction or used in the construction of new plants (Photo 3).

Implementation of the new technology on the mills of the types described above consistently provides the following results. In single-grade milling, as a rule, 69-71 % of flour with a whiteness of 58-59 units is obtained. Two-grade milling is carried out with the yield of flour of the highest grade 57-65 % (whiteness 60 units, ash content 0,49-0,51 %), as well as flour of the first grade (whiteness 43-45 units, ash content up to 0,72 %) up to the total yield of 73-74 %. At the same time, the flour of the highest grade is characterised by an attractive marketable appearance (without visible ‘flecks’ and grey shade). At three-grade mills, the total flour yield is 74-75 %, which is ensured by the selection of 2-3 % of second-grade flour. The actual productivity of the mills increases by 20-25 %, and power consumption does not exceed 70 kW per tonne of processed grain.

The table shows the results of milling at the mill with a capacity of 100 tonnes per day, reconstructed with the use of ‘Cascade’ machines. In addition to the introduction of debranning in grain preparation, the milling department was also significantly modified. By shortening two systems, the length of the roller line was reduced by 17 %, and the released part of the screening surface was used to reduce the amount of ‘undersowing’ and as a result – product turnover. According to the results of reconstruction the total length of the roller line was 1200 cm with the total area of screening surface of 58,2 square metres. The milling department includes 4 dredging, 2 sorting, 2 grinding and 4 milling systems. The grinding and two milling systems are realised using micro-roughened rolls. In turn, the milling systems with micro-roughened rolls are equipped with entolayers. The enrichment of grits and dung products is carried out in two double-hulled sieve machines. Two milling machines are provided for additional milling of shell particles. It should be noted that the data given in the table are obtained when processing grain containing fine fraction up to 15 %. In spite of this fact, the indicated results, at least, are not inferior to the results of milling at mills with productivity of 250-300 tonnes per day with developed structure of technological process realised by complete equipment. Besides, 30% less electric power is used for processing a tonne of grain, and 1.5 times less capital investments in equipment and construction part are required for creation of production of identical productivity.

Summing up the general result, we note that the implementation of the technology, characteristic fragments of which are described above, on dozens of existing mills of different productivity and equipment, as well as its use in the creation of new production facilities, confirmed its effectiveness and allow us to talk about the achieved practical successes.

Table. Results of operation of a mill with a capacity of 100 tonnes per day

| single-grade

milling |

two-grade

milling |

triple-grade

milling |

|

| Ash content of initial grain, % | 1,7 | 1,79 | 1,7 |

| Ash content of grain on the 1st dredging system | 1,47 | 1,61 | 1,55 |

| Flour yield, %, whiteness, units/ ash content, % |

71,6 59 / 0,52 |

69,0 59 / 0,51 |

63 60 / 0,49 |

| Flour yield 1/s, %, whiteness, units/ ash content, % |

——- | 4,7 47 / 0,68 |

7,6 46 / 0,68 |

| Flour yield 2/s, %, whiteness, units/ ash content, % |

——- | ——- | 5,3 21 / 1,15 |

| Total flour yield, % | 71,6 | 73,7 | 75,9 |

| Batch weight, tonnes | 1895 | 976 | 3290 |

| Average daily throughput, tonnes per day. | 100,4 | 100,3 | 100,7 |

| Electricity consumption per tonne of grain, kW/t | 74,4 | 74,3 | 75,5 |

published in

‘Grain storage and processing’.

№9 2008 г.