t is commonly known that successful crop growing is largely conditioned upon minimization of costs when harvesting. For loss prevention, the harvest should be started immediately with the onset of ripeness of grains and be carried out rhythmically and rapidly. Ripe grains in the field are not always dry, especially when it comes to later crops. In addition, even dry grains are frequently threshed together with the moist components of cultivated plants and weeds. These circumstances significantly reduce the threshing efficiency. Therefore, despite the use of modern combine harvesters, it is natural that after harvesting, the grain mass has increased humidity and clogging, low flowability and pore space, causing a risk of self-heating. Such grain mass must be immediately cleaned and, if necessary, dried. Even with a high level of new harvesting equipment, the rate and rhythm of the harvest significantly depend on the performance of post-harvest grain cleaning. Delayed grain cleaning not only increases the threat of spoilage, but also leads to downtime of service vehicles and harvesting equipment, as well as to crop losses in the field.

Post-harvest grain cleaning includes the stages of preliminary and primary cleaning, which, if necessary, are used depending on the conditions of the harvested grain mass and further use of grains. Pre-treatment is removal of coarse, large, small and light impurities or some of them, depending on the need. Its purpose is to quickly remove wet impurities, which provides temporary storage of grains before drying as well as gaining flow characteristics, which is necessary to perform this operation. In addition – as part of the pre-treatment – dry but excessively clogged grain mass which contains more than 10% impurities is cleaned. The purpose of this pre-treatment is to increase the flow characteristics of grains in order to ensure effective implementation of the primary cleaning stage. In its turn, the purpose of primary cleaning is to bring the content of grain impurities to a level that meets the requirements of state standards or other requirements for their delivery, and is the removal of light, large and small impurities. At this stage, dry grains with a content of weed impurities in the range of 3-10% are subject to be cleaned.

A distinction is made between sequenced-flow and periodic technology of post-harvest grain processing. Periodic technology is used solely at agricultural enterprises by means of separate, often self-propelled vehicles operating in open and closed areas. This technology is characterized by significant resources of manual labor, grain losses and a decrease in quality. The current level of crop yield and the use of the cutting-edge grain combine harvesters provide a significant daily volume of grain output and high harvest rates under the conditions of agricultural enterprises. Therefore, along with the above mentioned disadvantages, periodic technology is too unproductive, even for farms with small areas under crops. In our opinion, the use of periodic technology of post-harvest grain cleaning is possible when employing no more than one modern grain combine harvester during harvesting.

Sequenced-flow technology is free from the disadvantages inherent in periodic technology. In Soviet times, this technology was implemented on ZAV-type assemblies and KZS-type complexes; however their quantity production has been eliminated starting since 1991. Therefore, all the preserved units mentioned above are out-of-date, operate long after being worn out, with deterioration even of structural units and require replacement. In addition, under modern conditions, such units are characterized by low both production capacity and manufacturing efficiency. For these reasons, the rate of harvesting at farms is restrained, and grains due to multiple forced passage through transport mechanisms and machines of ZAV assemblies and KZS complexes deteriorates, including damage to seeds. There are attempts made by some farms to apply the so-called two-stage technology, when the preliminary processing of grain mass is carried out during the harvesting period, and the subsequent cleaning takes place in the post-harvest period. At the same time, it seems that there is a cost and maintenance saving due to machines of lower productivity and increase in their load time. However, such organization of work requires additional labor resources, and the forced grain overload by chains of transport mechanisms leads to its injury and loss. Truly modern assemblies and complexes for the ongoing grain processing at farms are rare.

Taking into consideration the above mentioned issues present at agricultural enterprises, post-harvest grain processing is increasingly done by both elevators, which are an integral part of agricultural enterprises, and by separate enterprises. Until recently, post-harvest grain cleaning was not considered a task that was to be solved at elevators. Therefore, even nowadays, specialists in elevator design do not always have a clear idea of the ins and outs of post-harvest cleaning, which would make it possible to opt for effective process design solutions and equipment for its implementation. Among the existing elevators, there are few of them that meet the requirements of effective post-harvest processing due to the fact that during their design no solution to this issue was introduced. Particularly problematic is processing of sunflower seeds, soybeans, rape seeds and maize – the crops that make up the largest volumes in the operation of elevators. Thus, the technology and equipment for post-harvest grain processing is one of the main components that affect the efficiency of grain production in general. At the same time, nowadays namely this component urgently requires scientific argumentation and technical solutions tested through practice.

For 15 years, the OLIS team has been developing technologies, designing manufacturing equipment and implementing in the grain processing industry. The priority areas of our activity are processes and machines for grain cleaning. Hundreds of grain cleaning machines manufactured by OLIS Company operate in different countries, under different conditions and process various types of grains. Generalization of theoretical insights and accumulated experience provides us with the opportunity to clearly and simply formulate the main points of an effective technology for post-harvest grain cleaning and the features of equipment for its implementation.

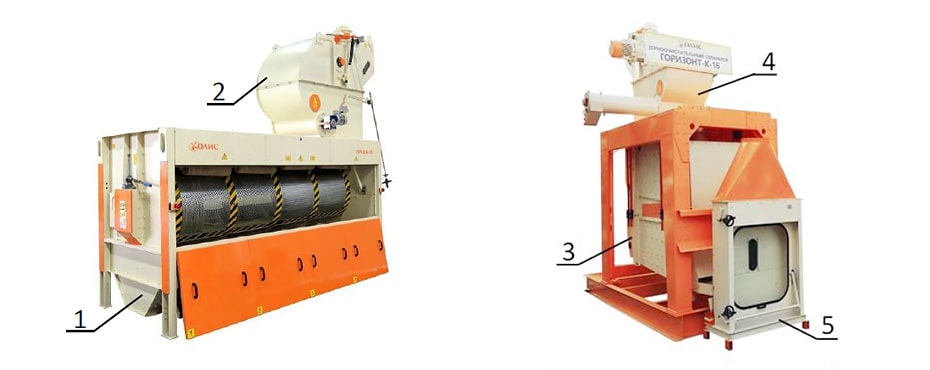

When selecting equipment for post-harvest grain cleaning with the view to rationally use the construction volume and area, preference should be given to aggregate machines – sieve-air separators combined into one structure (Fig.).

Fig. Sieve-air separators.

I – drum separator (1) with a closed-cycle separator (2);

II – flat-sieve separator (3) with pneumatic separators of the closed-cycle type (4) and open-cycle type (5).

For preliminary cleaning, it is necessary to use drum sieve separators as soon as these machines are able to process grains of any kind, any humidity or level clogging. The grain mass which enters the separator drum rotates by force on its inner surface and is stirred by the blades, which makes it possible to create the necessary conditions for its sifting and moving through the machine. In most cases, the sieve drum is divided into several sections along its length, which allows setting the necessary sieves in each section to implement a particular cleaning scheme. This design facilitates differential distribution of the active area of the sieves to separate large and small impurities or use the entire active area to separate only small or only large impurities. This feature is especially important for preliminary cleaning of grains before drying, when it is necessary to remove the most dangerous type of impurities with maximum performance. Natural distribution of grains in the drum makes it possible to use only a third of its total sifting surface, therefore, drum separators are characterized by increased dimensions. However, drum separators are the slow-moving machines which do not generate dynamic loads, so they can be installed either on most existing building structures without reinforcing them or on various temporary structures.

In separators with flat sieves, wet and heavily clogged grains characterized by reduced flowability, do not always acquire movement under the influence of machine vibrations, ensuring stable sifting through sieves and moving through the machine. In this case, the internal cavities of the separators with flat sieves are completely clogged, and their operation stops. Therefore, these machines can be effectively used for processing dry and not very clogged grains, that is, at the stage of primary cleaning. Most often, flat screen separators consist of one or more tiers of screens. Each tier of sieves contains an upper (sorting) and lower (sowing) sieve. Grains are fed simultaneously to the sorting sieve of each tier and large impurities are removed immediately. The passage of the sorting sieve is directed to the sowing sieve by the descent from which purified grains are obtained, and fine impurities pass. The specified cleaning scheme is unchanged for separators of this type. Only sieves are subject to operational change in accordance with the required shape and size of their openings. However, almost the entire screen surface of such separators is usable. In addition, the design of separators with flat screens contributes to the creation of machines with significant areas of screening surface. Therefore, it is advisable to use separators with flat sieves for thorough cleaning of large volumes of grains that have undergone preliminary cleaning and drying.

At the stages of preliminary and primary cleaning, it is required to provide for light impurity selection in the pneumatic separators. The operation principle of most pneumatic separators is implemented by blowing the falling flow of grains with upward air flow. At the preliminary cleaning stage, the pneumatic separator must be installed in front of the sieve separator since separation of light but wet impurities further improves screening the grain mass on the sieves. At the stage of primary cleaning, taking into account the efficiency of separation of light impurities, it is useful to implement double cleaning in the pneumatic separators, for this reason the machines are installed before and after the sieve separator. Due to the method of using air, pneumatic separators can be of closed or open-cycle type. In case of open-type machines, the exhaust air is emitted into the atmosphere. For this, they are additionally equipped with air ducts, a fan, cyclones or filters of significant performance as well as for the dimensions which are outside the pneumatic separator. Such solutions lead to an increase in construction volumes and areas for additional equipment and significant air emissions that reduce the environmental performance of enterprises. In closed-type machines, air moves under the action of a built-in fan and, upon cleaning in the sediment chamber of the machine, returns into the working area again, and the released light impurities are taken out in a separate flow. It is logical that the use of closed-type air separators is a more appropriate solution.

When selecting separators due to performance indicators, it should be borne in mind that in most cases, the manufacturers of these machines specify the so-called machine nominal capacity, which corresponds to the actual performance of the machine processing relatively dry and clean grains, which is inherent in the initial cleaning stage. However, experience has proven that with an increase in the content of impurities by every 5% and an increase in humidity by every one per cent, the production capacity of grain cleaning machines decreases by about 2.0%. Thus, the nominal capacity of machines at the stage of preliminary cleaning should be 1.5-2.0 times higher than the performance of machines at the stage of primary cleaning. In its turn, the production capacity of cleaning machines is related to the efficiency of their operation. With an increase in production capacity, the cleaning efficiency decreases. It should be noted that in the modes of post-harvest grain cleaning, the efficiency of most sieve separators and pneumatic separators is in the range of 40-60%, relative to impurities that can be separated in a correspondent way! Smaller and larger efficiency values are characteristic for the preliminary and primary cleaning stage respectively. If necessary, an increase in cleaning efficiency can be achieved by reducing the production capacity.

It follows from the above that for efficient operation of the elevator at the post-harvesting stages, the chain of the manufacturing line of its working tower should contain an intake pit, a pneumatic separator, a drum-type sieve separator, a bunker for raw grains with active ventilation, a dryer, a bunker for dry grains, a sieve separator with flat screens, a pneumatic separator and conveying mechanisms, including the grain feed for long-term storage. In the traditional sense of the purpose of the scalping machine, its installation at the beginning of the manufacturing line is optional. Separation of coarse impurities in the form of root crops, stones, bricks, wood, elevator buckets, etc. is successfully performed by a drum-type sieve separator, which removes them together with the flaw of large impurities.

At agricultural enterprises, sequenced-flow post-harvest processing technology can be implemented on the model of ZAV or KZS with varying degrees of structure development, where a sieve-air separator with a drum-type sieve separator will be the only machine used for alternate grain processing in the preliminary or primary cleaning mode.

At small agricultural enterprises, sequenced-flow post-harvest processing technology can be set up without facilities on the model of ZAV or KZS by means a sieve-air separator with a drum-type sieve separator. In this case, the separator is installed in the warehouse, storage shed or under roof on a temporary platform with a height of 1.5-2.0 m, equipped with an intake pit of any design, as well as with an elevator for feeding grains to the separator and an elevator for feeding grains into the warehouse or to the farm-type dryer. Auxiliary operations for movement of grains and waste are carried out by means of a MANITOU loader and vehicles.

In conclusion, it should be noted that post-harvest processing is associated with the requirement for cleaning different types of grains, and grain mass can contain a wide variety of weeds with various impurities. Therefore, for effective cleaning, sieve separators should be equipped with quite a large number of different sieves for each type of crops, and pneumatic separators should provide for regulation in a wide range of operating modes. Selection of sieves, setting the operating modes of sieve separators and pneumatic separators in relation to each manufacturing situation should be carried out by a qualified specialist who has been appropriately trained.

Please send your questions, pointed comments and suggestions to:

E-mail: olis88@ukr.net