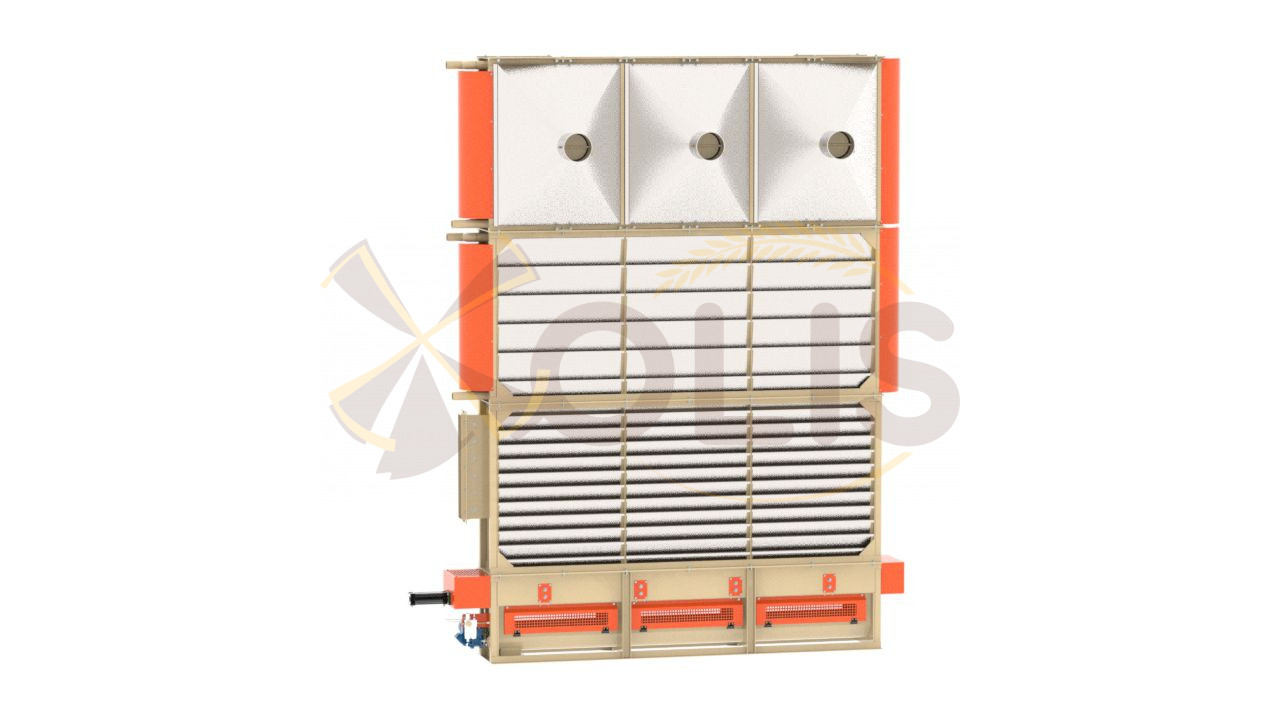

Vertical dryer VPS-O

Vertical dryer VPS-O, manufactured by OLIS Ltd, is designed for drying grain of groats crops in the process of hydrothermal treatment during groats production. The initial product sequentially passes through the drying sections, where it contacts with pipes heated by steam. After that, the grain enters the cooling section, where it is cooled by blowing with air, and then removed using a special exhaust mechanism.

Product Description

Specifications

Аdvantages

Video/Photo

Additional Information

Описание

Описание

Олис

Олис

Purpose and scope of application:

Vertical dryer VPS-O, manufactured by OLIS Ltd, is designed for drying grain of groats crops in the process of hydrothermal treatment during groats production.

Description:

The initial product sequentially passes through the drying sections, where it contacts with pipes heated by steam. After that, the grain enters the cooling section, where it is cooled by blowing with air, and then removed using a special exhaust mechanism.

Specifications

Выберите модель

| Model | VPS-O-3 | VPS-O-4 | VPS-O-5 | VPS-O-6 | VPS-O-7 | VPS-O-8 |

| Number of heating sections, pcs. | 3 | 4 | 5 | 6 | 7 | 8 |

| Heating area, m2 | 40,5 | 54,0 | 67,5 | 81,0 | 94,5 | 108,0 |

| Productivity, t/h | 1,0-1,3 | 1,5-1,7 | 2,0-2,2 | 2,4-2,6 | 2,9-3,1 | 3,3-3,4 |

| Steam pressure, kPa | 400 | 400 | 400 | 400 | 400 | 400 |

| Steam consumption per ton of grain, kg/h | 280-360 | 280-360 | 280-360 | 280-360 | 280-360 | 280-360 |

| Air consumption per ton of grain, m3/h | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Power of electric drives, kW | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 |

| Weight, kg | 3040 | 3750 | 4460 | 5170 | 5960 | 6690 |

Аdvantages

- Drying sections are equipped with the device for connecting to forced ventilation, which contributes to intensification of drying process;

- The cooling section is equipped with the cooling air distribution and adjustment device, which helps to evenly cool the product;

- The device of the release mechanism has been improved, which makes it possible to ensure the uniform release of the product with a given capacity, including in automatic mode;

- Number of pipes in the drying sections has been increased, which ensures high drying rates of the product;

- Due to presence of separate throttles in the cooling section, precise and smooth adjustment and uniformity of cooling are achieved;

- The design of the outlet section realizes optimal expiration of the product, which ensures high quality of product processing;

- Use of components from leading European manufacturers.

- Stainless food steel is widely used in the machine, due to which high sanitary and hygienic properties of the machine are observed.

Photos

Выберите модель

| Model | VPS-O-3 | VPS-O-4 | VPS-O-5 | VPS-O-6 | VPS-O-7 | VPS-O-8 |

| Number of heating sections, pcs. | 3 | 4 | 5 | 6 | 7 | 8 |

| Heating area, m2 | 40,5 | 54,0 | 67,5 | 81,0 | 94,5 | 108,0 |

| Productivity, t/h | 1,0-1,3 | 1,5-1,7 | 2,0-2,2 | 2,4-2,6 | 2,9-3,1 | 3,3-3,4 |

| Steam pressure, kPa | 400 | 400 | 400 | 400 | 400 | 400 |

| Steam consumption per ton of grain, kg/h | 280-360 | 280-360 | 280-360 | 280-360 | 280-360 | 280-360 |

| Air consumption per ton of grain, m3/h | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Power of electric drives, kW | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 |

| Weight, kg | 3040 | 3750 | 4460 | 5170 | 5960 | 6690 |

- Drying sections are equipped with the device for connecting to forced ventilation, which contributes to intensification of drying process;

- The cooling section is equipped with the cooling air distribution and adjustment device, which helps to evenly cool the product;

- The device of the release mechanism has been improved, which makes it possible to ensure the uniform release of the product with a given capacity, including in automatic mode;

- Number of pipes in the drying sections has been increased, which ensures high drying rates of the product;

- Due to presence of separate throttles in the cooling section, precise and smooth adjustment and uniformity of cooling are achieved;

- The design of the outlet section realizes optimal expiration of the product, which ensures high quality of product processing;

- Use of components from leading European manufacturers.

- Stainless food steel is widely used in the machine, due to which high sanitary and hygienic properties of the machine are observed.

X