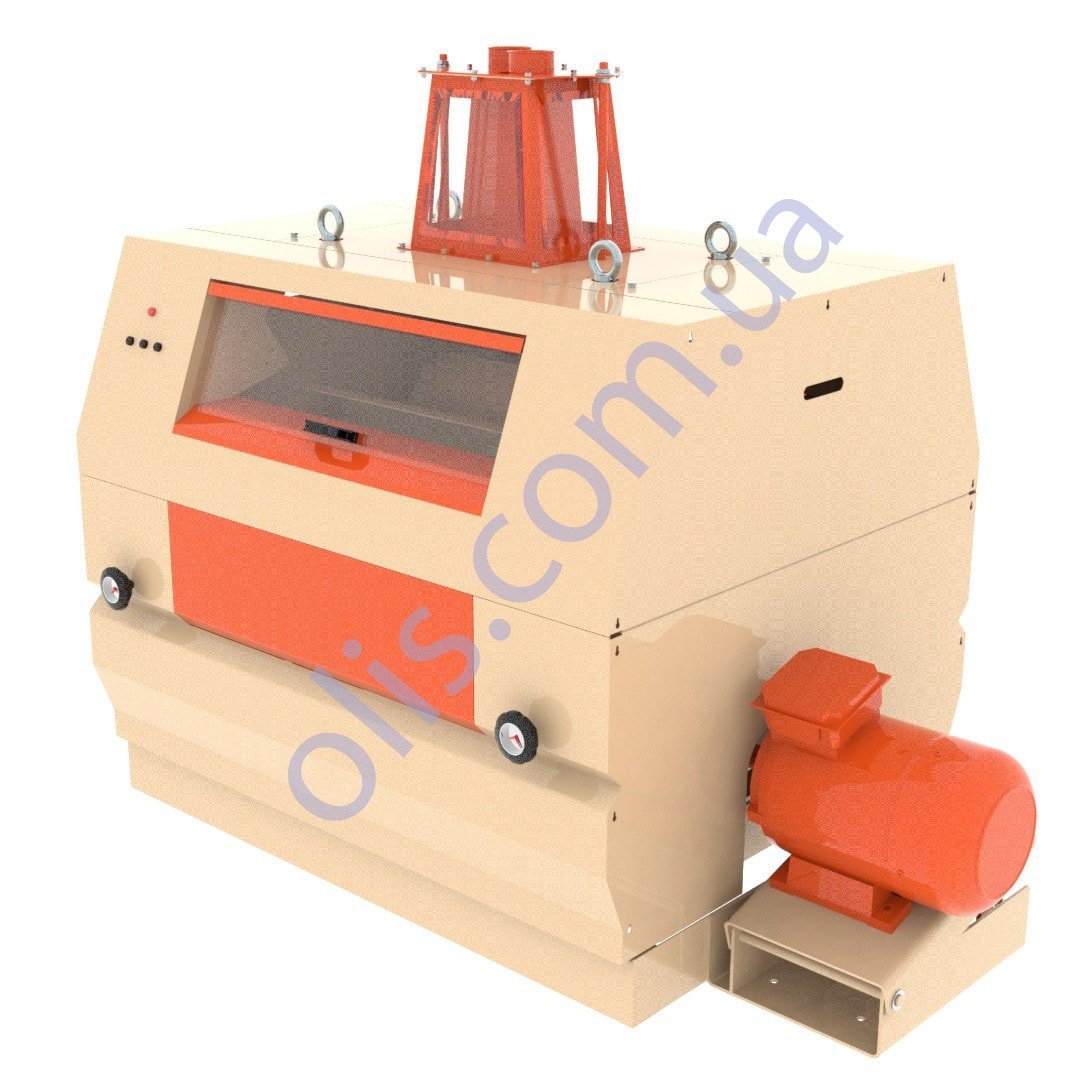

Roller mill VSM

Roller mill VSM is designed for grinding grain and intermediate products of cereal crops at flour and groats enterprises.

Product Description

Specifications

Аdvantages

Video/Photo

Additional Information

Описание

Описание

Олис

Олис

Purpose:

Roller mill VSM is designed for grinding grain and intermediate products of cereal crops at flour and groats enterprises.

Specifications

Выберите модель

| Model | VSM-800 | VSM-1000 |

| Roller diameter, mm | 250 | 250 |

| Roller length, mm | 800 | 1000 |

| Maximum power of one pair of rollers, kW | 18,5 | 18,5 |

| Number of rollers | 2 pairs | 2 pairs |

| Operating mode | continuous with 3-shift work |

continuous with 3-shift work |

| Frequency of rotation of high-speed rollers, rpm | 436 | 436 |

| Reduction factor for low-speed rollers: for grinding pair for breaking pair |

1,25 2,33 |

1.25 2,33 |

| Overall dimensions, mm length x width x height |

2865×1515×1925 | |

| Weight, kg | 3920 |

Аdvantages

- The belt drive is adopted, which greatly reduces noise level.

- Feed roller speed is automatically adjusted according to the level of the feeder products, which greatly reduces the number of stall/dump cycles, and increases the service life of the mechanism.

- Digital indication of current consumption, overload protection.

- Convenient and fast replacement of grinding rolls, assemblies and mechanisms.

- Use of rollers manufactured by one of the world leaders, Entil (Turkey).

- High efficiency and reliability.

- Small size and energy consumption, which makes it easy to maintain and operate the machine.

Photo

Выберите модель

| Model | VSM-800 | VSM-1000 |

| Roller diameter, mm | 250 | 250 |

| Roller length, mm | 800 | 1000 |

| Maximum power of one pair of rollers, kW | 18,5 | 18,5 |

| Number of rollers | 2 pairs | 2 pairs |

| Operating mode | continuous with 3-shift work |

continuous with 3-shift work |

| Frequency of rotation of high-speed rollers, rpm | 436 | 436 |

| Reduction factor for low-speed rollers: for grinding pair for breaking pair |

1,25 2,33 |

1.25 2,33 |

| Overall dimensions, mm length x width x height |

2865×1515×1925 | |

| Weight, kg | 3920 |

- The belt drive is adopted, which greatly reduces noise level.

- Feed roller speed is automatically adjusted according to the level of the feeder products, which greatly reduces the number of stall/dump cycles, and increases the service life of the mechanism.

- Digital indication of current consumption, overload protection.

- Convenient and fast replacement of grinding rolls, assemblies and mechanisms.

- Use of rollers manufactured by one of the world leaders, Entil (Turkey).

- High efficiency and reliability.

- Small size and energy consumption, which makes it easy to maintain and operate the machine.

X