Fluidised Bed Drier for flakes SKHO

Purpose and scope of application:

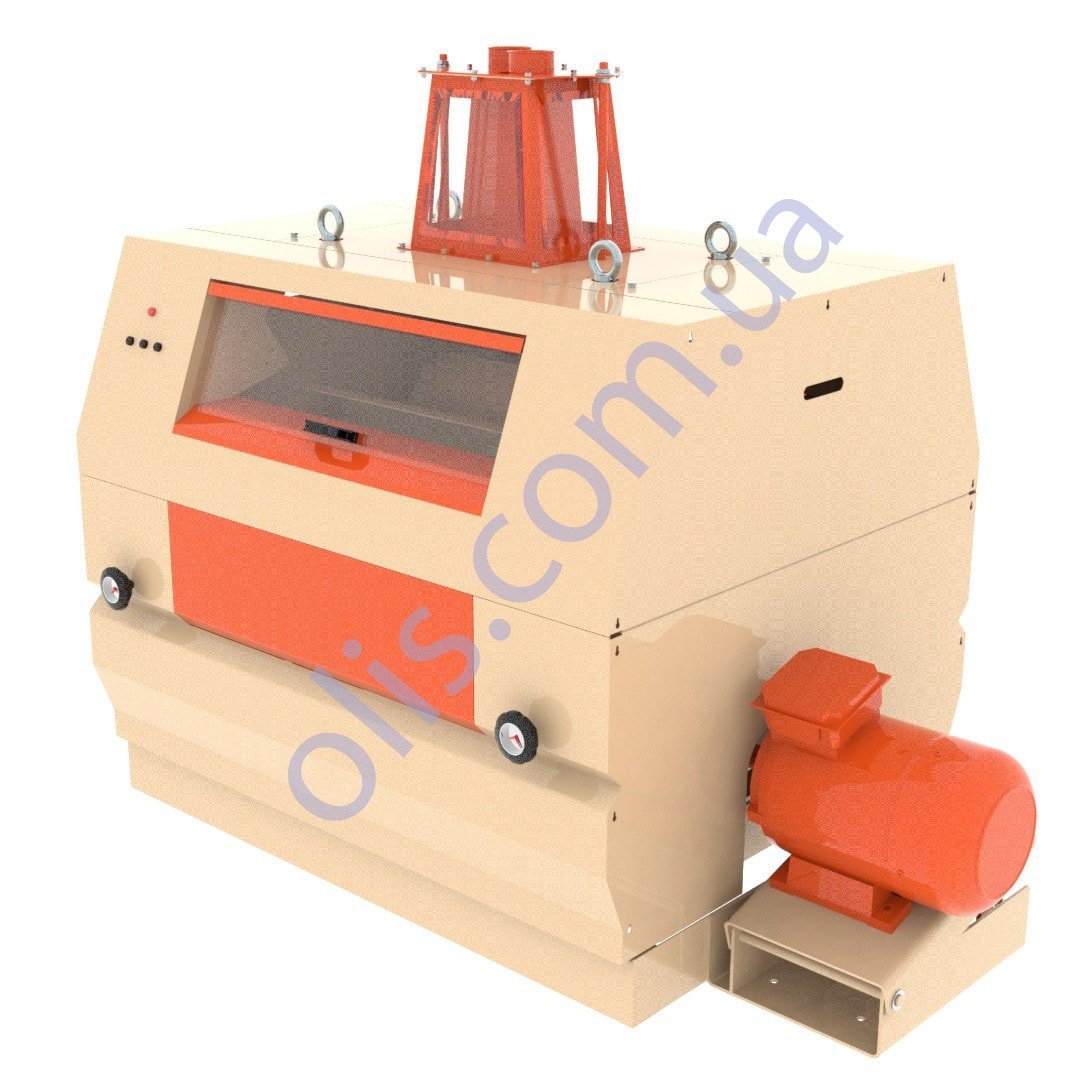

Fluidised bed drier for flakes SKHO, manufactured by OLIS Ltd, is designed for heat treatment (drying and cooling) of air-blown flakes.

Description:

The initial product enters the drying zone of the sieve. This heat treatment is carried out by the air fluidization method, in which air is forced through the product in the direction opposite to gravity, bringing this product into a fluidized state. Each particle of the product is washed with air, so that the maximum external surface of the product is provided for air drying. The product is constantly moving from the point of loading to the point of unloading, which eliminates its overheating. Hot air coming through the fan and heaters is supplied to the drying zone of the sieve, and cold air is supplied through the fan to the cooling zone of the sieve. The dried and cooled product is discharged through the outlet.

Specifications

| Model | SKHO-150 | SKHO-300 | SKHO-500 |

| Productivity up to, kg/h | 500 – 700 | 1000 – 1500 | 1500 – 2000 |

| Sieve area, m2 | 1,5 | 3,0 | 5,0 |

| Weight, kg | 480 | 1000 | 1270 |

| Overall dimensions, mm length width height |

2900 770 2300 |

4220 1200 2850 |

4420 1600 3150 |

Аdvantages

- The product layer regulator on the sieve ensures efficient drying of the product;

- Indication of supplied air temperature;

- Components from leading European manufacturers are used.

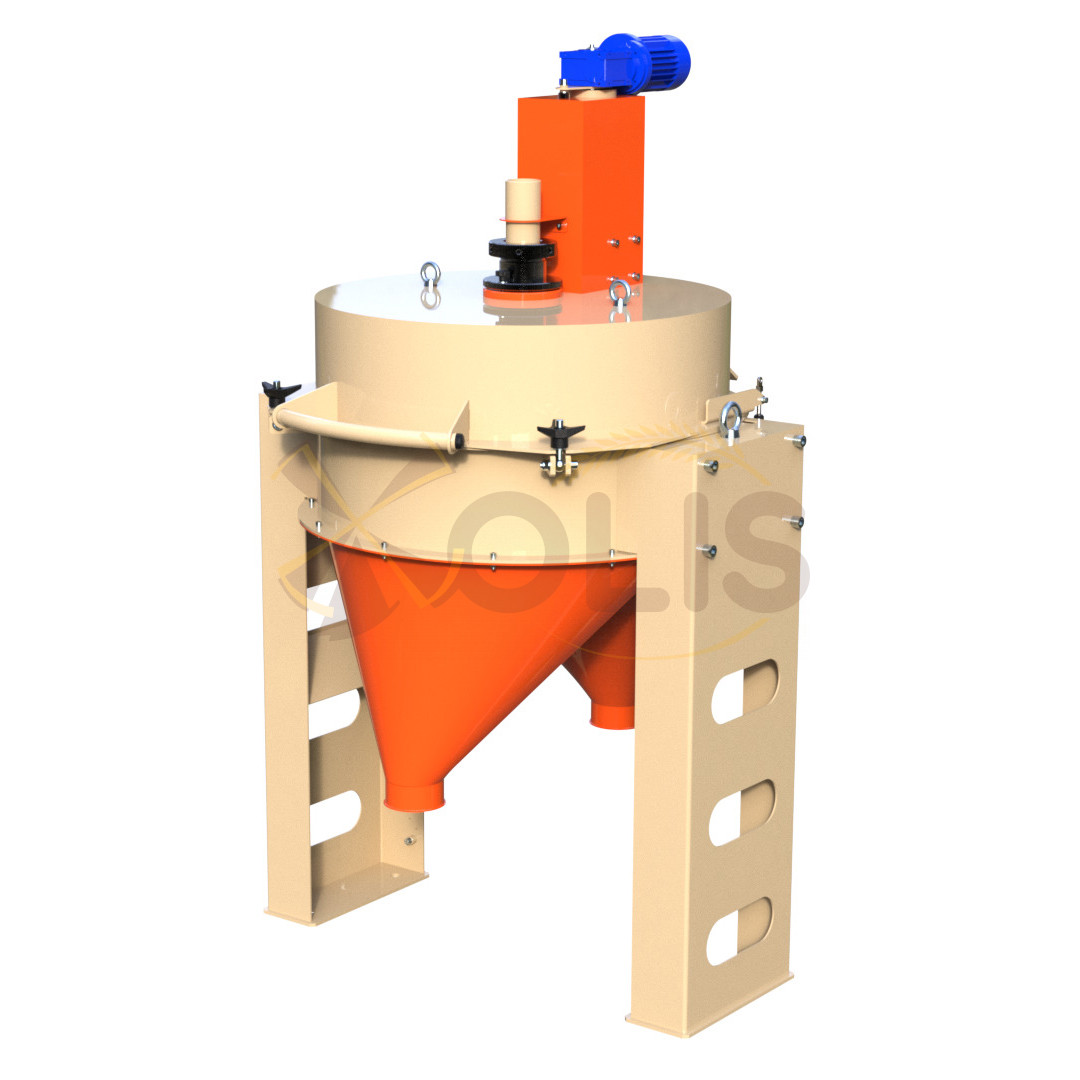

Photos

| Model | SKHO-150 | SKHO-300 | SKHO-500 |

| Productivity up to, kg/h | 500 – 700 | 1000 – 1500 | 1500 – 2000 |

| Sieve area, m2 | 1,5 | 3,0 | 5,0 |

| Weight, kg | 480 | 1000 | 1270 |

| Overall dimensions, mm length width height |

2900 770 2300 |

4220 1200 2850 |

4420 1600 3150 |

- The product layer regulator on the sieve ensures efficient drying of the product;

- Indication of supplied air temperature;

- Components from leading European manufacturers are used.