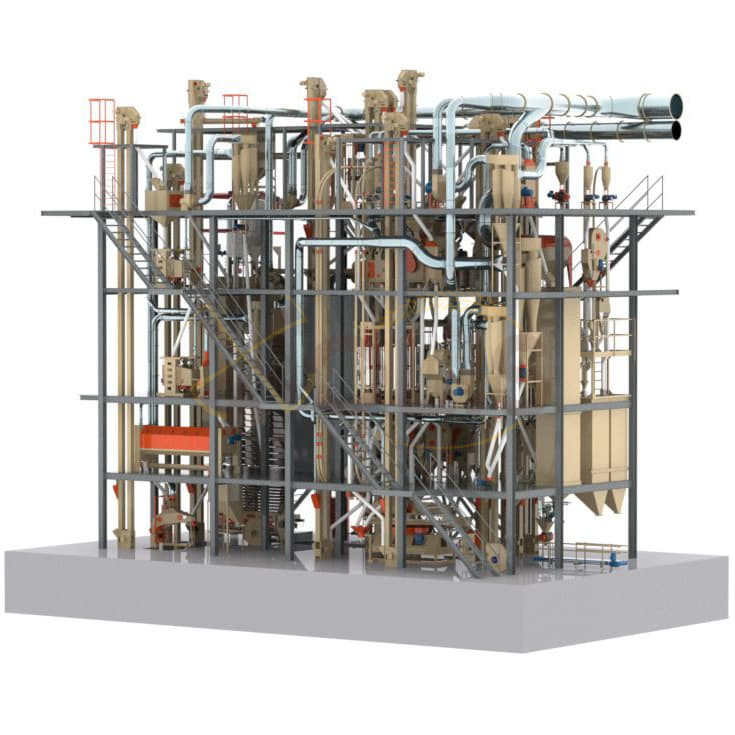

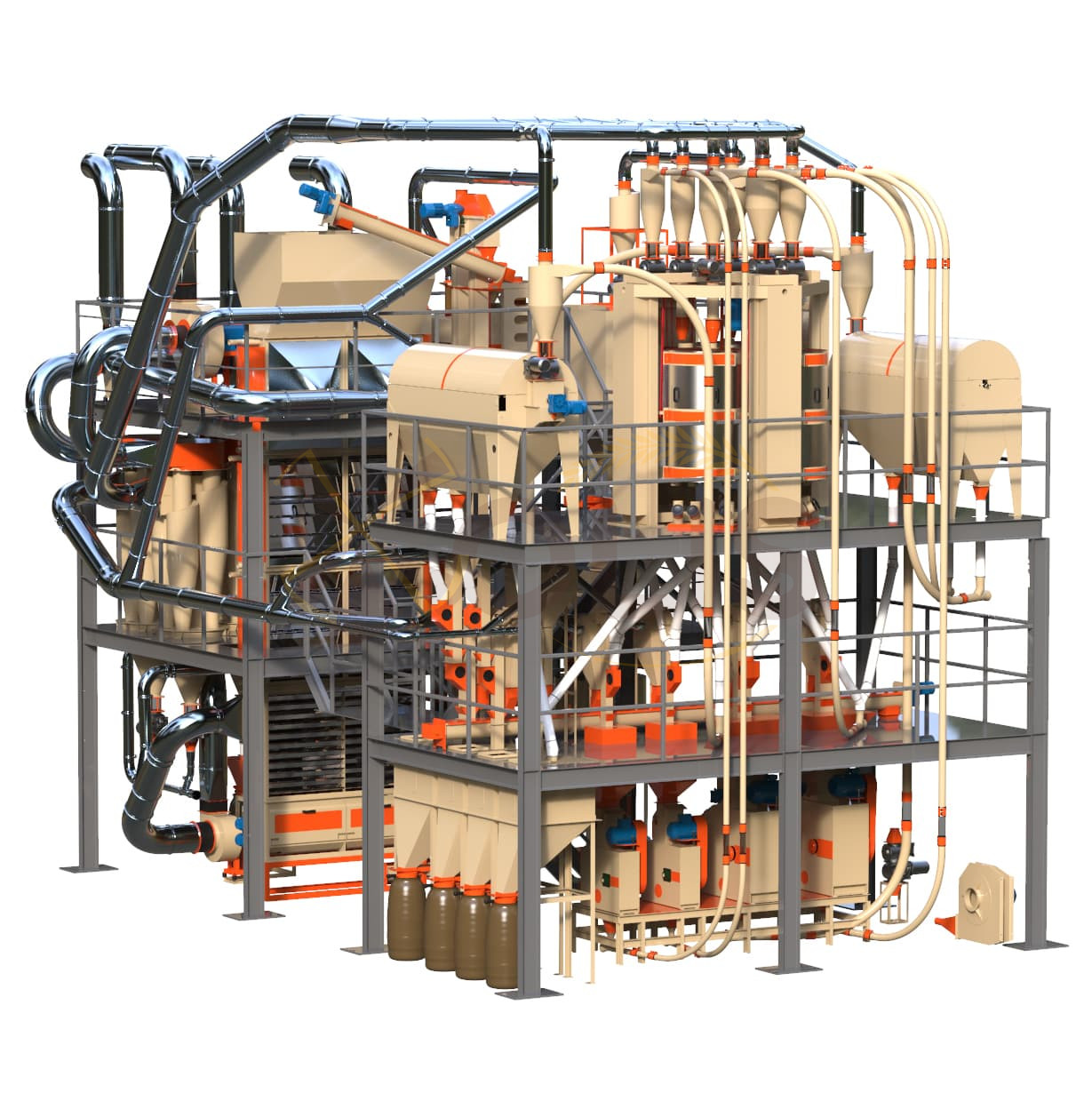

The complete buckwheat processing plant with productivity 36 t/day

Purpose

The complete buckwheat processing plant has been designed for buckwheat processing with productivity 36 t/day. Design and equipment of the groats plant provides the quality of groats – not below the requirements of GOST, yield of groats – above the accepted norms and allows you to confidently meet the requirements of the market. The plant was created by traditional technology, which includes hydro-thermal treatment by steaming. The proposed technology is significantly improved and supplemented by a number of OLIS innovations.

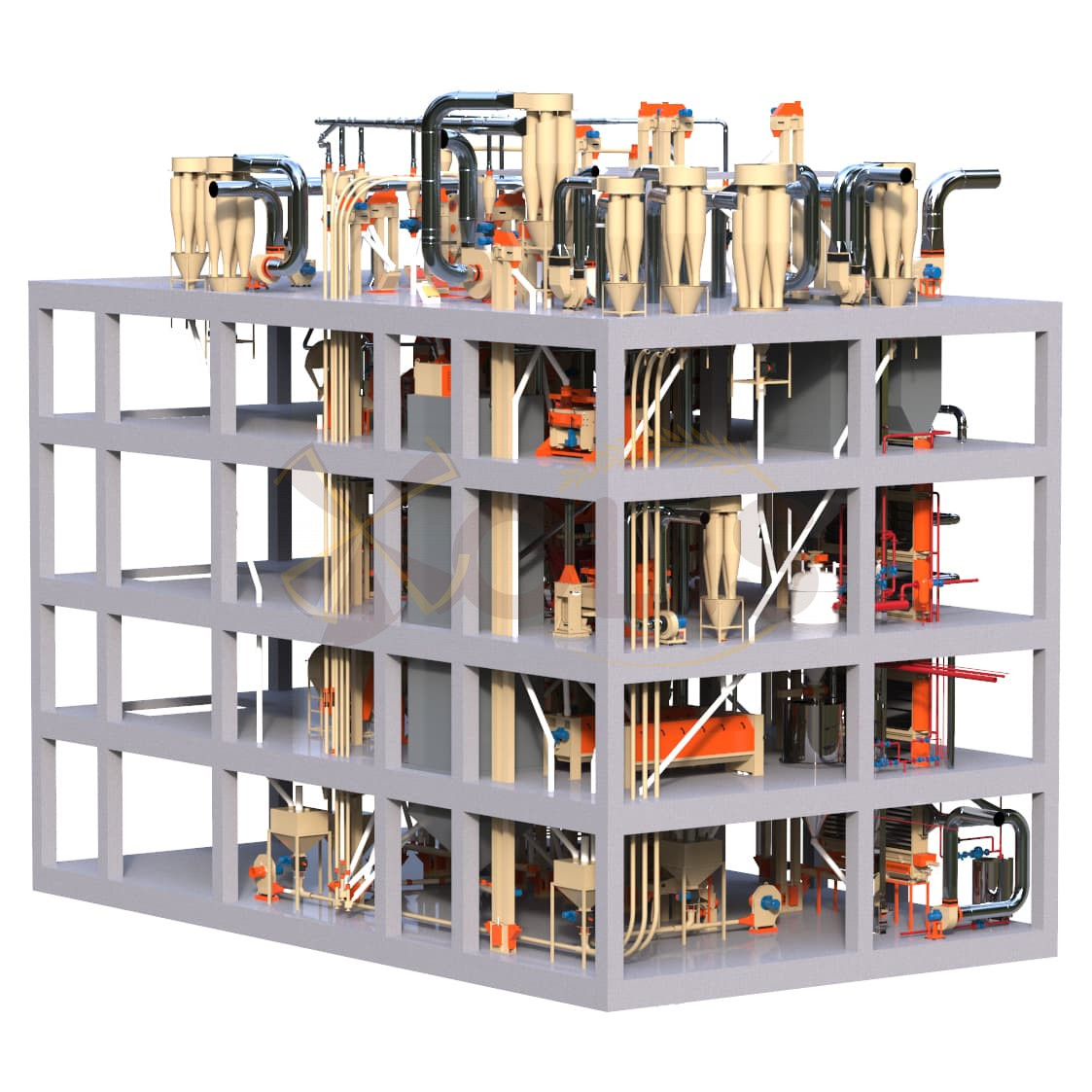

For plant placing, a 4-storey building with a floor height of at least 3 m and an area of each floor of at least 160 m2 is appropriate. In the absence of a suitable building, it is recommended that the supporting metal structure for equipment placement be made in the form of a four-level frame up to 12 m high with dimensions of 9 m x 18 m in plan and installed on its own foundations. In this case, it is advisable to equip the external fences (walls and roof) on reinforced concrete structures and foundations, independent of the metal structure supporting the equipment. Estimated height of the building is 14 m.

As part of fulfilment individual project to the plant can be tied such utilities as:

- The receiving line of grain from vehicles and pre-cleaning;

- Warehouse placement and storage of the operative stock of grain with the line of its supply to the processing;

- Weight-unloading section with the possibility of selecting the finished product both in bags and in small packaging;

- Warehouse bulk storage of flours and husks with a line of loading on trucks;

The plant operate in automatic mode. The operator from the central control desk provides control of the plant.

The basic yield of groats (from grain of basic conditions):

Characteristics:

Equipment composition of the plant

Аdvantages

- The highest yield and quality of groats in the class of aggregate plants for buckwheat processing.

- Efficient processing of low-grade grains without reducing the quality of groats.

- Ability to produce buckwheat groats without the use of hydro-thermal treatment, i.e. “green”.

- Compactness and low power consumption, which allows the operation of the groats factory in various adapted rooms.

- Operation of the plant is in automatic mode.

- Reliability of the equipment ensures uninterrupted and long-term operation of the plant.

Photos

The basic yield of groats (from grain of basic conditions):

Characteristics:

Equipment composition of the plant

- The highest yield and quality of groats in the class of aggregate plants for buckwheat processing.

- Efficient processing of low-grade grains without reducing the quality of groats.

- Ability to produce buckwheat groats without the use of hydro-thermal treatment, i.e. “green”.

- Compactness and low power consumption, which allows the operation of the groats factory in various adapted rooms.

- Operation of the plant is in automatic mode.

- Reliability of the equipment ensures uninterrupted and long-term operation of the plant.