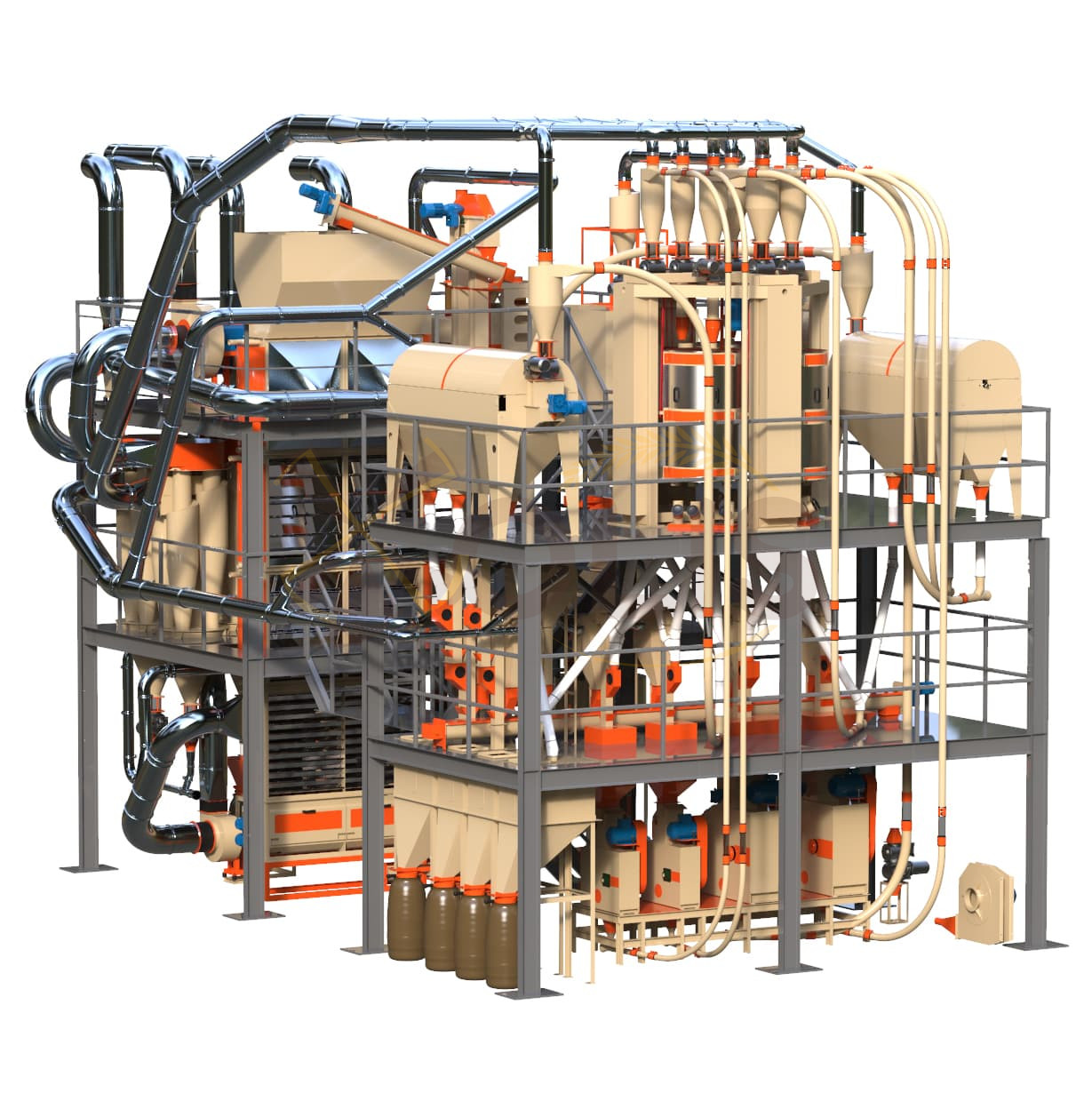

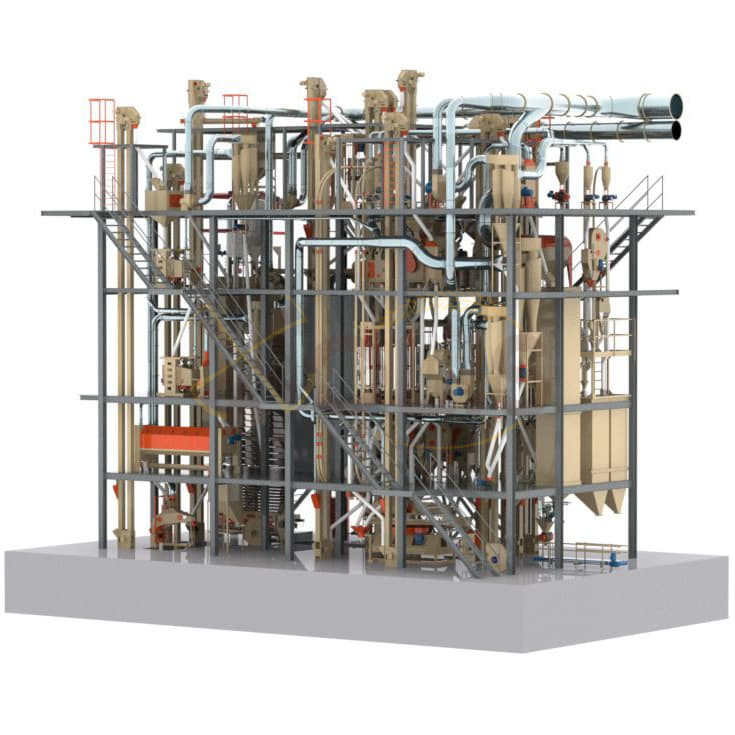

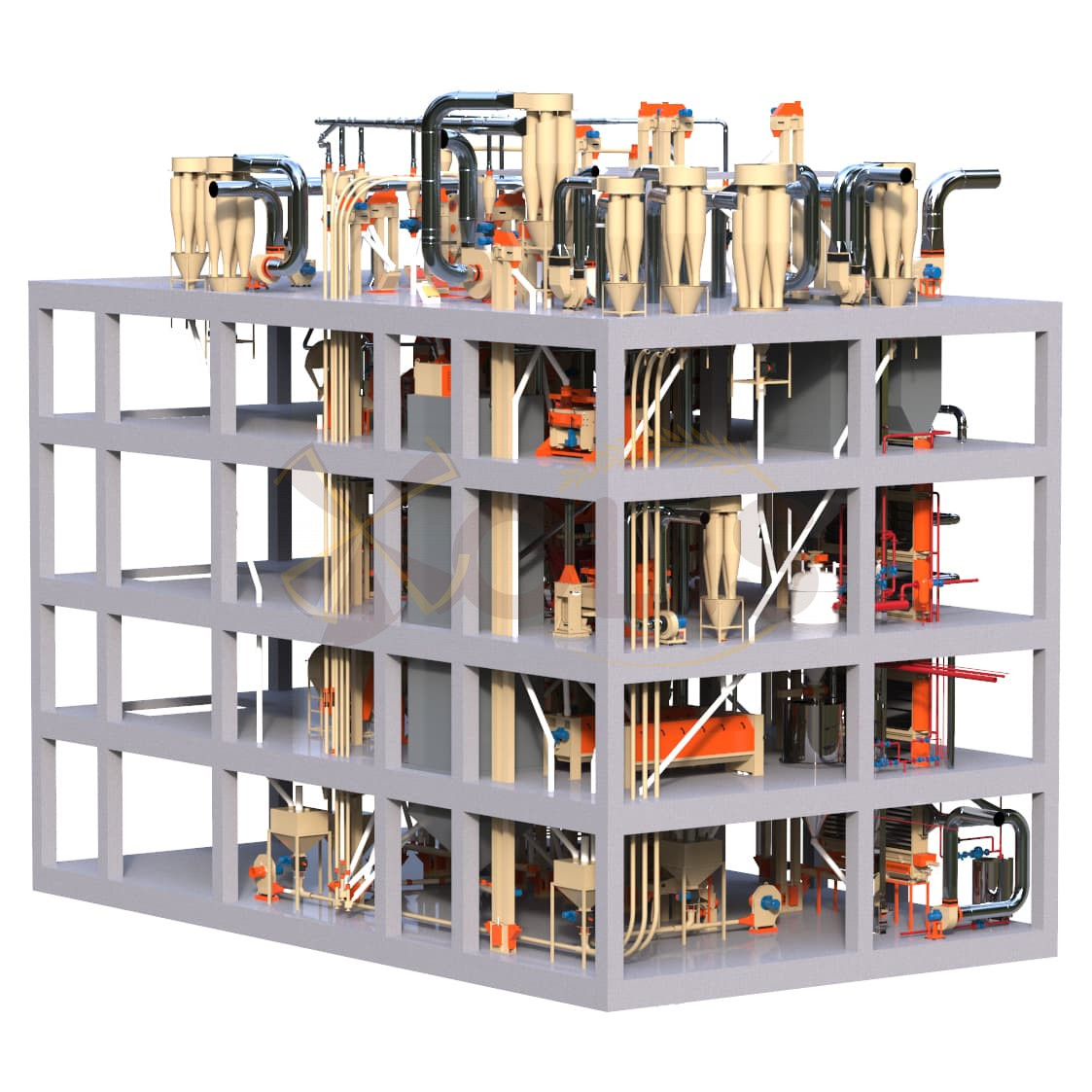

Aggregate buckwheat processing plant with productivity 24 t/day

Purpose

The aggregate groats processing plant “OPTIMATIK-G-24” has been designed for buckwheat processing. Design and equipment of the groats plant provides the quality of groats – not below the requirements of GOST, yield of groats – above the accepted norms and allows you to confidently meet the requirements of the market. The plant was created by traditional technology, which includes hydro-thermal treatment by steaming. The proposed technology is significantly improved and supplemented by a number of OLIS innovations.

The aggregate groats processing plant “OPTIMATIK-G-24” is supplied with metal construction, ladders and service platforms, bunkers, aspiration system, pneumatic transport system, electrical part and automatics. Since the manufacture of the plant passes the stage of control assembly, its complete assembly and commissioning at the place of operation take no more than three weeks. In this case, the need for cutting, welding, and drilling of metal at the place of assembly is completely eliminated. The plant operates in automatic mode. The operator controls the operation of the plant from the central control panel.

Characteristics

The basic yield of groats (from grain of basic conditions):

Аdvantages

- The highest yield and quality of groats in the class of aggregate buckwheat groats plants.

- Efficient processing of low-grade grains without reducing the quality of groats.

- Ability to produce buckwheat groats without the use of hydro-thermal treatment, i.e. “green buckwheat”.

- Compactness and low power consumption, which allows the operation of the groats factory in various adapted rooms.

- Operation of the plant is in automatic mode.

- Reliability of the equipment ensures uninterrupted and long-lasting operation of the plant.

Photo

The basic yield of groats (from grain of basic conditions):

- The highest yield and quality of groats in the class of aggregate buckwheat groats plants.

- Efficient processing of low-grade grains without reducing the quality of groats.

- Ability to produce buckwheat groats without the use of hydro-thermal treatment, i.e. “green buckwheat”.

- Compactness and low power consumption, which allows the operation of the groats factory in various adapted rooms.

- Operation of the plant is in automatic mode.

- Reliability of the equipment ensures uninterrupted and long-lasting operation of the plant.