Vereshchynsky A.P., Ph.D.

Catalog LLC OLIS “2005.

Recent years, much of the flour produced in mills with low productivity. These include the mill capacity of 25 – 60 tons / day grains with reduced quality grinding circuits.

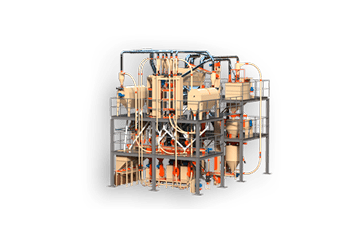

Photo. 1. Machine for cleaning grain surface.

The main feature of the mills of this type is to use “short” circuits grinding grain, consisting of 8, 6 or even 4 systems. Providing a high yield of flour in such schemes require a significant amount of its recovery in torn processes, which is achieved by maintaining low mode grinding. Such regimes is usually characterized by not high quality flour for chopping hulls of grain, as well as penetrating into the large part of the impurities contained in the grain. Moreover, the low modes to a minimum reduces the number of pellet, and thus a higher quality flour that is obtained by grinding processes. It is quite clear that the shortage clot enrichment process can not significantly change the overall balance of flour to higher grades and in most of the schemes available. Thus, the current controversy quality output of flour at mills of this type are insoluble in the grinding of their offices. Effective solution to this problem is connected with the need to significantly improve the quality of flour in torn processes and, as experience shows, is ensured by the higher requirements for the preparation of grain for grinding. These include not only a thorough cleaning and bringing grain in the best condition for grinding through conditioning, but also to make substantial progress to reduce its ash content. Successful completion of the task is aggravated by the specific conditions of low-capacity mills, which include limited resources, communications, and working space and, hence, limited opportunities for used fleet.

Analysis of the mills with low productivity, both domestic buildings, and foreign production, shows that reduced training schemes traditionally used equipment can not adequately provide the above stated requirements. To solve this problem requires the development of new technology and machinery for their implementation. Considering the effectiveness of the preparation of grain for grinding, as the main factor in increasing the performance of the mills with low productivity, our company has successfully implemented training schemes that contain fragments of the new technology being implemented specifically to create the machine. Such equipment is designed to handle flows of 1.3 m / h and is highly effective in reducing schemes.

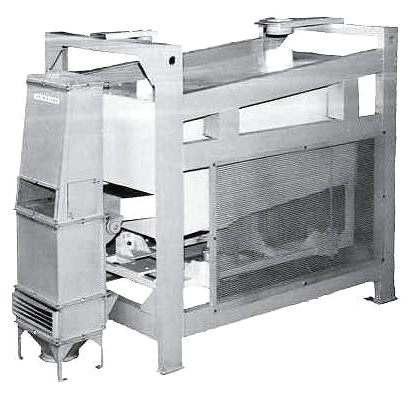

Air- sieve separator is equipped with a tier unload sieve, 40 – 60% reduces the load on sieve screens, increasing the efficiency of their work. Improved design sits sieve framework excludes litter and facilitates the replacement of screens when they are mandatory selection for each batch of grain. Kinematic characteristics of the separator body movements similar to the vibrations plansifters and, together with a reliable purification system screens create the best conditions for screening.

Machine for surface cleaning involves the use of Towpath, brushing, grinding or a combination of rotors, as well as sieve or brush in December. Gentle or more intense exposure given an arsenal of tools in conjunction with the organization of air traffic “in effect” allows us to achieve the desired effect in a particular installation of such machines in the scheme.

Machine Cascade-M enables a deep, uniform surface treatment of grain without loss of endosperm, as well as the allocation of most of hardshare impurities and low-value grains by their destruction.

Air separator, aspirator closed-loop air and suction speakers are designed with the ability to maximize the visual control processes of pnevmoseparation. Specified machines feature high-precision division, which has attracted more zones of separation, evenness of air flow and stability of grain flows in a wide range of adjustments.

Moistening grain segment “high speed” screw using rotameters and feeder ensures proper mixing and mutual dosage of grain and water. In most cases, at the expense of compromising the integrity of the shell and the heating of grain as a result of intensive surface treatment can be limited to one phase of conditioning, followed by up to moisture and short conditioning before the first ragged system. In the cold season conditioning gives a good effect heating of moistened grain termobunker continuous settling under which one of the bunkers conditioning. Under such conditions, the gradients of temperature and moisture at the same time directed into the grains of increasing the rate of penetration of moisture and reducing thereby the time of conditioning.

Using the above tools allow to thoroughly clean grain to reduce its ash content in the initial 0,2 – 0,4%, and also to make the necessary changes in structural and mechanical properties that can already ragged on the first system to extract 15 – 17% white flour 56 – 58 units .

Retrofitting in accordance with the above domestic mills and mill Dutch, Danish, Turkish and other production permit to produce up to 76% of profiled flour from which the 60 -70% white flour. Recoupment of funds for upgrading is 3 – 4 months at the paper mill clock.