by O.P. Vereshchinsky,

Doctor of Engineering Science,

General Director of ‘OLIS’ LLC, Odesa

Any type of grain processing is associated with cleaning from impurities. The presence of impurities adversely affects the efficiency of storage of grains and their technological characteristics, which results in decrease of the yield and quality of processed products. Therefore, cleaning operations are instrumental in post-harvest grain processing. Manufacturing processes for the production of flour, cereals, alcohol, bioethanol, mixed feed, as well as malt also begin with cleaning operations. Grains always contain impurities. Most impurities enter the grain mass during harvesting in the form of various anatomical components of cultivated plants and weeds, pieces of soil, insects, etc. During operations with grains, various random objects may get into the bulk – e.g. stones and sand from both thrashing-floor platforms and concrete structures of elevators, metal components of conveyance and grain processing machines. Any movement of grains is associated with intense friction of the grains among themselves, as well as on the working bodies and other surfaces of the machines, which causes the appearance of dust, so dust is always a component of grain bulk.

All impurities contained in grains are divided into weed and grain impurities. Weed impurities include seeds of all weeds, impurities of mineral and organic origin, highly defective grains of the basic crops, as well as metal impurities. Harmful impurities which can adversely affect the health of people and animals are separately distinguished and classified as weeds. These are the seeds of knapweed, coronilla and seeds of basic crops affected by smut, spur, fusarium disease. Grains containing harmful impurities are not allowed for use for food purposes. Grain impurities include grains of other crops, broken grains of the basic crops, thin, underdeveloped, germinated and heat-damaged grains, in some cases, grains that differ in color. Impurities are undesirable constituents of grains, therefore, their content, depending on the type and purpose of grains, is limited by state standards, and recommended by the rules of organization and conduct of various technological procedure of processing, or is established by the parties during supplies.

The methods used for grain cleaning are determined by signs of separation of the basic grains and impurities. Most of the impurities that are present in the grain mass can be divided into eight classes, which determine five groups of processes of their separation from the basic grains: coarse, large and small grains – screening on sieves; light grains – pneumatic separation; metal-magnetic grains – separation by magnets; long and short grains – sifting; heavy grains – vibration pneumatic method, impurities that differ in optical features – optical sorting.

In a production environment, the efficiency of the cleaning processes and machines that implement it is determined by the following formula:

Е = (Х1 – Х2) / Х1,

where Х1 and Х2 – the initial and final content of impurities in the grains, %.

It should be noted that if the evaluation of the cleaning efficiency is carried out for individual processes and machines, then the initial and final contents of only those impurities that can be removed in an appropriate way are taken into account..

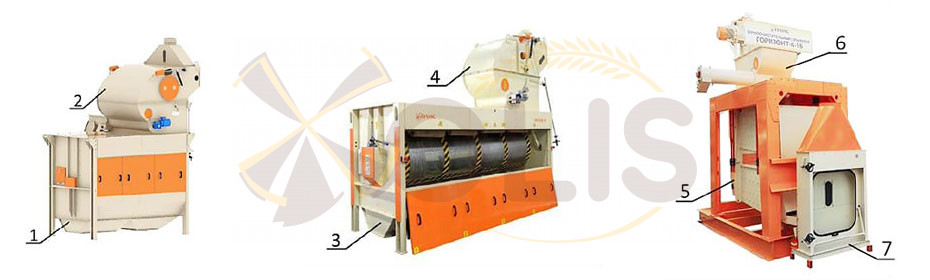

Impurities separated by screening on sieves and pneumatic separation are considered to be easily separable impurities. Sieve and air separators of various designs with their connection into a single unit are designed to separate such impurities (Fig. 1).

Fig 1. Sieve-air separators.

I – a drum scalper (1) with an open-type pneumatic separator (2);

II – a drum separator (3) with a closed air separator (4);

III – a flat-screen separator (5) with a closed-type pneumatic separator (6) and an open-type pneumatic separator (7).

Cleaning grains from coarse impurities is carried out by sifting through a sieve with large holes, at the beginning of the production lines. Removing such impurities eliminates emergency situations due to the ingress of large stones, bricks, wood, root crops, etc. into the conveyance and manufacturing machines. Usually a variety of screen separators is used to perform such an operation – scalpers that are equipped with a sieve in the form of a short drum or a movable lattice.

For the separation of grains and impurities which differ in width and thickness, separators are used, equipped with working bodies in the form of cylindrical or flat screen surfaces with round, oblong or triangular openings, made in a thin steel sheet (punched metal sieve). The sieve is the main working body of such separators and both performance and technological efficiency of sifting significantly depends on its characteristics. Therefore, along with the use of traditional sieves, it is important to search for designs of sieves with improved characteristics. For example, the use of sieves made of metal rods, punched metal sieves with oblong holes of different orientations in the plane or pentagonal holes. In many cases, such sieves have essential advantages.

Separators with cylindrical screen surfaces (drum separators) are characterized by the balance of the screen drum, which rotates at a slow rate, by reliable design, as well as by high efficiency of the cleaning sieves with brushes and hammers. However, the working surface area of the screens of such machines is about 30% of their total area, which results in some increase in the dimensions of the structure. At the same time, cylindrical separators are indispensable in wet and heavily impure grain processing. Separators of this type are capable of efficient processing of weakly loose and prone to caking grain masses with high production capacity. In addition, the use of drum separators eliminates the need for scalpers. It should be noted that some designs of scalpers provide for the replacement of sieves with punched metal sieves with any size of holes, which makes it possible to use them to isolate not only coarse impurities, but also large impurities. Efficiency of cylindrical screen separators is in the range of 50-70%, and 100% for the separation of coarse impurities.

Separators with flat screen surfaces (flat-screen separators) differ in the type of oscillation of their screen bodies, which provide screening of the grain mass. Machines that implement directional vibrations are characterized by a limited surface area of the sieves. Such separators are sometimes used in mills and groat-milling plants, where there is no need for processing batches of significant capacities. Separators that implement reciprocating motion of the sieves are distinguished by the complexity of the design, therefore, are also limited in use. Their use is justified for the thorough grain processing, for example, for seed calibrating.

The most common separators with double roll motion of the screen bodies. Such separators have high production capacity, because they can be equipped with sieve body frames with a significant area of the sieve surface and have a wide field of application both at elevators and during grain processing. The disadvantages of flat-screen separators include some generation of dynamic loads on the engineering structures of buildings and facilities. In addition, with a decrease in the centrifugal acceleration of the screen body frames, which is sometimes desirable to ensure the efficiency of sieving, insufficiently effective operation of inertial cleaners is observed. This negative effect is especially evident when using sieves with oblong holes. Efficiency of most flat-screen separators is in the range of 60-80%.

Pneumatic separators are intended to separate light and dusty impurities – which include puny and underdeveloped grains, shells, flooring, straw, etc. – from the grain mass. The vast majority of pneumatic separators are made in the form of vertical channels in which the grain mass falling under the influence of gravity is blown upward by air. Due to the method of air use, there are air separators of open and closed type. Open-type pneumatic separators emit used air into the environment. For this, they are additionally equipped with air ducts, an external fan, cyclones or filters. In closed-type pneumatic separators, after air purification in the built-in sedimentary chamber, it is re-fed into the pneumatic separation zone under the action of the built-in fan. The process of pneumatic separation requires a significant air flow, which is needed to create certain conditions for removing impurities. Therefore, closed-type pneumatic separators have significant advantages, since they neither pollute the environment with emissions nor require powerful additional devices for operation. The efficiency of grain cleaning from light impurities in pneumatic separators is 65-75%.

Impurities that cannot be removed by the sieve-air method are classified as difficult to separate. To remove impurities that are difficult to separate, the remaining machines are intended, which will be considered below (Fig. 2).

Removal of metal-magnetic impurities is carried out due to the difference in the magnetic properties of grains, their products and impurities, which is implemented by means of magnets. The operating body of magnetic separators is a group of permanent magnets, closed by a screen of non-magnetic material and built into the case with doors. The grain mass flows by gravity into the magnetic separator, flows around a screen that traps metal-magnetic impurities and flows out of the device by gravity. When the conveyance line stops, the trapped impurities are periodically removed from the magnetic separators manually. Metal-magnetic impurities are very diverse in size, shape and origin: objects accidentally falling into the grain mass (nails, pieces of metal, iron ore, steel oxide, etc.) and particles fallen into the grain mass as a result of wear and tear of the operating bodies of the grain processing machines (pieces of sieves, sieve surfaces, pests, etc.). Presence of such impurities in the grain mass can cause severe damage to the machines, as well as to the appearance of flashes, which pose a threat of fire or dust and air explosion. Undesirable and dangerous is the ingress of metal-magnetic impurities into the finished product: flour, cereals, mixed-feed, etc. Therefore, magnetic protection is provided at all enterprises for grain processing and especially in front of the machines that implement grinding, peeling, flattening, granulation, etc.

Fig 2. Machines for removing difficult to separate impurities.

1 – magnetic separator; 2 – trieur; 3 – grain destoner; 4 – gravity table; 5 – optical sorter.

For separation of impurities that differ in length, grain processing in trieurs is used. In the grain mass of wheat, a short admixture is represented mainly by cockle, field peas, broken grains of the main crops, while a long admixture is represented by wild oats, oats, and barley. If an impurity that is shorter than the crops is selected from the grain mass of any crops, then it is common practice to call such a trieur a cockle remover. If an impurity that is longer than the crops is selected from the grain mass of any crops, then such a trieur is usually called a wild-oat remover. The working bodies of the trieurs are represented by a cellular surface made on the inside of a rotating horizontal cylinder. The sifting process is based on the fact that upon contact with the working surface, the particles are ‘carried away’ by the cells, removed from the grain mass and under the influence of gravity, fall into the collection tray, and the long ones remain on the working surface and are removed from the machine. With regard to grains of any crops, the trieur cockle remover structurally differs from the trieur wild-oat remover solely in the size of the cells of its working surface. The efficiency of the trieur cockle remover and the trieur wild-oat remover is 80-90% and 80-85% respectively. In accordance with the applicable standards, sifting is considered effective if in such a way at least 80% of the impurity can be separated by one trieur at a time.

For removal of heavy impurities and separation by the specific weight, the vibration pneumatic method is used, which is implemented in grain destoners, gravity tables, concentrators, combinators and sieve purifiers. The separation process of grain mass occurs by using an upward air flow in combination with vibrations of the sorting surface. D this method, particles of grain mass, being in a fluidized state, experience multiple collisions between themselves and the sorting surface, which leads to their intense self-sorting. Separation is carried out in such a way that the lower layers, consisting of particles of higher density, are sifted through the sorting surface (concentrators, sieve purifiers) or sent along it in the opposite direction of movement of particles with lower density (grain destoners, gravity table separators). Concerntrators, combinators and sieve purifiers are used in the production of flour; therefore their further consideration in the framework of this operation is not appropriate.

Grain destoners are used to separate mineral impurities from the grain mass (pebbles, coarse sand, pieces of ore, slag, pieces of earth, etc.), they are distinguished by high production capacity, compact design and efficiency of 98-99%.

Grain destoners are used to separate mineral impurities from the grain mass (pebbles, coarse sand, pieces of ore, slag, pieces of earth, etc.), they are distinguished by high production capacity, compact design and efficiency of 98-99%.

The main disadvantage of the machines that implement the vibration pneumatic separation method is the use of air in an amount of 450-600 m3 per 1 ton of grains, which is released into the environment upon cleaning from dust. Therefore, a promising direction for improving such machines is introduction of closed air circulation into their design.

Optical sorting is undeniably a new advanced rapidly-developing technology. However, there is already considerable experience of the use of optical sorters in the industry, which allows us to determine the boundaries of their appropriate use. The optical sorter is a machine that mainly uses the difference in surface color as signs of separation, and is therefore valuable, since no other machine uses this feature. At the same time, it is necessary to understand how much such a sign of separation corresponds to the purpose of grain cleaning. A frequent mistake when using optical sorters is that they try to distinguish what is easily distinguished by simple and traditional methods of cleaning, due to their high efficiency, by the difference in color. Therefore, the use of optical sorters is not a substitute for traditional cleaning methods with alternative or more efficient methods, but a reasonable complement to them. Based on the practice, the use of optical sorters is advisable at the finishing operation of cleaning individual batches of seeds and finished products.

It can be seen from the survey that a variety of processes and machines for cleaning is determined by the manifold of physical and mechanical properties of grains and impurities. In addition, the modern organization of effective cleaning provides for its multi-stage. Depending on the condition of the grain mass and the purpose of cleaning, there is preliminary, primary and secondary cleaning.

Preliminary cleaning is mainly used as part of post-harvest grain processing and represents separation of coarse, fine, large and light impurities. Freshly harvested grain mass is characterized by high humidity and clogging, which determines its low flowability, duty cycle and causes the risk of self-heating. This problem is especially acute when harvesting late crops – sunflower seeds and maize. As a rule, significant moisture content of the grain mass is due to the high humidity of a certain component of it – plant residues. Therefore, the task of preliminary cleaning is rapid removal of damp impurities, which provides temporary storage of grains before drying and gaining flowability for them to be able to perform this operation. As noted, to solve this problem, the most effective is the use of sieve drum separators, aggregated with pneumatic separators (Fig. 1. I and II).

The purpose of primary cleaning is to bring the quality of grains to marketable condition. Such cleaning involves the removal of light, large and small impurities, which is also performed in sieve-air separators. Within the framework of the considered stage, dry grains with a content of weed impurities in the range of 3-10% is subject to thorough cleaning, which requires high efficiency of the separators, which means significant size of their sieve surface. Flat-screen separators aggregated with pneumatic separators both at the inlet and at the outlet of the screen body (Fig. 1. III) or drum separators aggregated with pneumatic separators (Fig. 1 II) meet these requirements.

If it is impossible to provide the necessary content of impurities by a single cleaning, re-passage of grains through a particular sieve-air machine is used.

By secondary cleaning, the grains are brought to a condition that meets the use requirements for food purposes or seeds. When performing secondary cleaning, the grains can also be processed many times in flat-screen air separators (Fig. 1. III) or drum separators (Fig. 1 II). However, since the necessary degree of purification at the stage of preliminary and primary purification is achieved by removing easily separable impurities, in most cases the main task of secondary purification is the struggle with hard-separable impurities. Based on the composition and characteristics of impurities, secondary cleaning may involve the use of some or all methods of separating hard-separable impurities, which were considered above: triering, vibro-pneumatic and optical methods (Fig. 2). As a rule, secondary cleaning is implemented within flour, cereal or seed production lines.

It should be noted that the production capacity and efficiency of cleaning significantly depend not only on the level of machine equipment with processing lines, but also on the proper selection of their working bodies (screens, mesh surfaces, inertial cleaners, etc.) and setting the operating modes of the machines for maximum use due to signs of separation of the basic grains and impurities in each specific case of the production situation.

Please send your questions, pointed comments and suggestions to:

E-mail: olis88@ukr.net