Present to your attention!

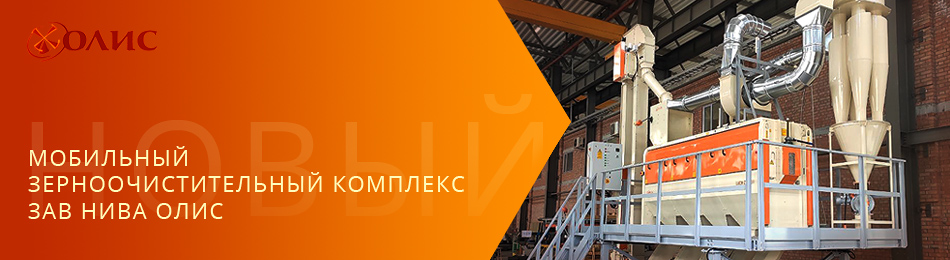

ZAV Niva mobile grain-cleaning plant,

based on the ZSO LUCH grain separator.

To date, we have mastered the production of three ZAV NIVA models on the basis of LUCH ZSO-35, LUCH ZSO-50 and LUCH ZSO-75 separators having the performance of 15, 25 and 50 t/h.

The plant is intended for preliminary and primary grain cleaning, as well as for sorting and calibration of grain and seeds.

The input grain from the receiving hopper is fed by gravity to the chain-bucket elevator, which transports the grain for cleaning to the LUCH ZSO grain cleaning separator comprising the air separator and the drum-type sieve separator.

In the air separator, the grain is cleaned from light impurities which are removed to the general aspiration network.

Then the grain enters the sieve separator, in which the grain is cleaned from large and small impurities.

The purified grain and impurity are removed from the separator through the outlet branch pipes.

The capture of light impurity and plant dedusting are provided for by the aspiration system comprising the cyclone, the fan and the air ducts.

The plant control is provided for by means of the central control panel with automation elements.

The huge advantage of this complex is that it is a modular solution that does neither require the foundation for deployment nor any earthworks.

The plant is supplied completely “turnkey”. During installation, only assembly is required, the metal welding and cutting works are not required.

ZAV has small dimensions, the design is very compact.

The time required for installation is minimum.

One of the main advantages of the plant is the LUCH ZSO drum-type grain cleaning machine, which is designed for cleaning all types of grain crops and performs the preliminary, primary and secondary cleaning of grain and seeds. The quality of cleaning in the separator is regulated by changing the drum inclination angle. The drum inclination angle and rotation frequency are adjusted automatically, depending on the type of grain to be cleaned and cleaning modes.

OLIS is a manufacturer company that produces the high-quality and reliable equipment, provides for the training for the service personnel and performs the works of any complexity.

For detailed information, please contact the Sales Department by phone:

+38 (067) 822-85-58

OLIS – the time-tested quality!

For detailed information, please contact OUR sales department by phone NUMBER:

☎ +38 (067) 822-85-58

OLIS – time-tested quality!