A.P. Vereshchinsky, Candidate of Technical Sciences, General Director of OLIS LLC

As is known, the task of varietal grinding is the most complete extraction of endosperm into the finished product by separating it from other anatomical parts of the grain. The degree of solution of this problem is the basis for assessing the level of technology, organization and conduct of grinding. It is on this principle that almost all methods for assessing the efficiency of grain grinding processes, which are still the subject of scientific research, are based. However, the effectiveness of any technology, among other things, is measured by the level of costs required to achieve a certain result, which is not taken into account when developing these methods. Thus, determining the technological efficiency of grinding processes is not enough for a final assessment of the technology’s effectiveness. As a result, a number of important questions relevant to any flour mill remain unanswered. For example, it is impossible to determine at what yield and quality of flour grinding will be effective, what efficiency to expect from processing grain of a certain technological value, or how to compare the efficiency of different grindings of different grains. Thus, the assessment of the effectiveness of technology, ensuring the success of business, must be technical and economic. The method ensuring its implementation must be characterized by objectivity, sufficient accuracy, efficiency and simplicity.

Using statistical data from the APK-Inform information agency, we analyzed the cost of various types of flour from 2004 to 2009. Selected data from such an analysis during periods of stable grain prices are given in Table. 1.

Table 1.

| No. p/p |

Time period | Cost grain, UAH/t |

Cost premium flour, UAH/t |

Cost flour 1 s, UAH/t |

Cost flour 2 s, UAH/t |

Cost bran, UAH/t |

| 1 | 08.2004 – 11.2004 | 640 | 1200 | 1050 | 880 | 250 |

| 2 | 03.2005 – 10.2005 | 580 | 1050 | 920 | 670 | 230 |

| 3 | 12.2005 – 08.2006 | 640 | 1125 | 950 | 710 | 320 |

| 4 | 09.2006 – 03.2007 | 790 | 1320 | 1130 | 980 | 510 |

| 5 | 11.2007 – 01.2008 | 1335 | 1780 | 1525 | 1440 | 800 |

| 6 | 02.2009 – 06.2009 | 1180 | 1995 | 1750 | 1510 | 540 |

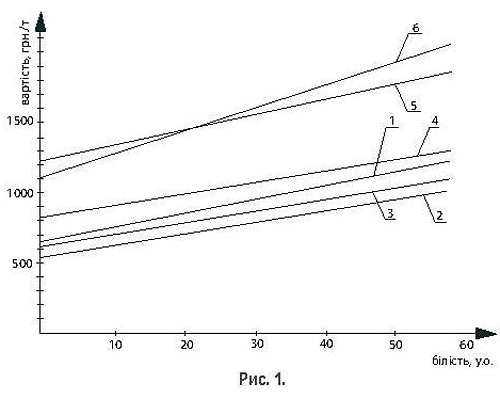

In recent years, flour whiteness has been used as an indicator of flour quality, characterizing the level of grain processing. This indicator is mandatory when determining the type of flour, and therefore its cost. In Fig. 1 shows graphs constructed from the table data, reflecting the cost of flour varieties based on its whiteness. At the same time, the numerical values of whiteness of flour varieties were selected according to the data of most well-known enterprises in the industry and for the highest, first and second grades they were 59, 44 and 20 conventional units of whiteness, respectively. As can be seen from the figure, the presented data obey dependencies that can be described by linear equations. Further analysis shows that the value of the free parameter of each equation coincides with the cost of grain in the corresponding period. A non-zero term reflects the level of the ratio of the cost of flour of different varieties and grains in different periods. Thus, the cost of flour Cb is determined by the relationship:Cb = A*B + Cz, UAH /t (1)

where A is an indicator that determines the dependence of the cost of flour on its whiteness, UAH/t.e. whiteness,

B – whiteness of flour, c.u., Cz – cost of grain , UAH/t.

Thus, the cost of flour of any type can be represented as the arithmetic sum of the cost of grain for a given period and the added value from processing, depending on the type (whiteness) of flour. The significant influence of the cost of grain on the cost of flour is natural, since about 90% of the costs in the production of flour are raw materials. The difference in cost between the grades (whiteness) of flour and grain is different in different periods, as it reflects the state of market supply and demand.

When using the above dependencies, the flour whiteness indicator acquires continuity, which coincides with practice. Indeed, premium flour with a whiteness of, for example, 56 units and 62 units have different market values, while first-grade flour with a whiteness of 36 units and second-grade flour with a whiteness of 35 units have approximately the same cost. Thus, the “whiteness” indicator not only determines the cost of flour in accordance with its grade, but also reflects the cost of different flours within the same grade.

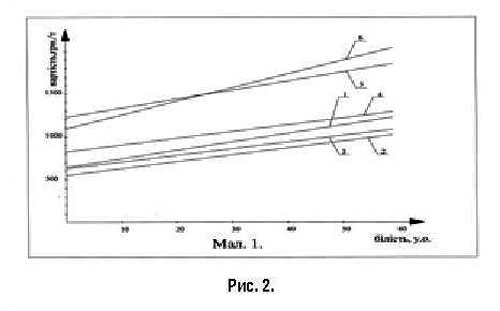

Taking into account dependence (1), the total cost of processed products obtained from a certain mass of used grain can be determined as the sum of the products of the mass of the corresponding type of flour and its cost, determined by the whiteness indicator. However, products that significantly affect the results of processing also include bran. Without taking into account this component, the definition of efficiency cannot be called complete. Of course, defining the whiteness of bran in a physical sense is absurd. However, if we extend the direct dependence of the cost of flour on its whiteness (Fig. 2) until it intersects with the value of the cost of bran Cb for the same period, then on the whiteness axis we will obtain a negative number B<, which is quite definite in the arithmetic sense sub>in, which can roughly be called “the whiteness of bran.” This conditional indicator is constant for the corresponding period and allows you to determine the cost of bran depending on the cost of grain. Its negative value, in contrast to flour, indicates that when part of the grain mass is converted into bran, the cost of this part decreases, which corresponds to the economic essence of processing. Thus, the total cost Cp of processed products obtained from a certain mass of grain Bz is determined by the expression:

where n is the number of processed products (flour by grade, bran),

Bi – whiteness of the i-th product, c.u., Bi —mass of the i-th product, t.

If both sides of equation (2) are divided by the cost of processed grain (Bz x Cz), then the value of K = C / Bз*Сз indicates how many times the cost of grain increases (decreases) as a result of processing, taking into account the yield of products and their quality, which fully characterizes the technical and economic efficiency processing. Thus, the K value can be used as a general criterion for processing efficiency.

For ease of use, we will write the expression in converted form:

where Bi is the output of the i-th product , %.

Taking into account the efficiency criterion K as a percentage provides convenience for comparative calculations and indicates by what percentage the total cost of processed products exceeds the cost of grain in each case. In addition, each component of the computational sum in expression (3) gives an idea of the contribution of each product to the level of processing efficiency.

Analysis of the dependence of the cost of flour on its whiteness and the cost of grain and bran for various periods shows that the “whiteness of bran” takes values of about 40 USD, and the value A averages 9 UAH/ i.e. Mathematical processing of the data showed that, taking into account the accuracy of the assessment, the given values are suitable for practical use. If necessary, it is not difficult to clarify the values of A and B for any period, based on the cost of flour by grade (cost of grain, bran) for the same period.

Published based on materials

“Grain storage and processing”

scientific and practical journal

№9 (123), 2009