NATIONAL UNIVERSITY OF FOOD TECHNOLOGIES

Alexander Pavlovich Vereshchynskyi

UDC 664.64.001.76

Scientific basis and practice

Improve the effectiveness of varieties

BAKER’S WHEAT GROOVES

05.18.02 – Technology of cereals, pulses, cereals

products and feed, oilseeds and bast crops

Author’s note

Dissertations for a scientific degree

Doctor of Technical Sciences

Kyiv – 2013

The dissertation is a manuscript.

The work was carried out at the National University of Food Technologies of the Ministry of Education and Science of Ukraine

National University of Food Technologies,

Professor of the Department of Grain Storage and Processing Technology

Kharkiv Petro Vasylenko National Technical University of Agriculture,

Head of the Department of Processing and Food Production Technologies;

Doctor of Technical Sciences, Professor Georgiy Mykolayovych Stankevich,

Odesa National Academy of Food Technologies,

Head of the Department of Grain Storage Technology;

Doctor of Agricultural Sciences, Professor Gumeniuk Galina Denisovna,

National University of Life and Environmental Sciences of Ukraine,

Head of the Department of Standardisation and Certification of Agricultural Products

The defence will be held “____”__________2013 at 1000 hours at the meeting of the Specialised Academic Council D 26.058.06 of the National University of Food Technologies (68 Volodymyrska St., Kyiv, 01601) in room A-311.

The thesis is available in the library of the National University of Food Technologies at 68 Volodymyrska St., Kyiv, 01601.

The author’s abstract was sent to “____” __________2013.

Scientific secretary of the specialised

of the Academic Council, Ph.

YU. Kambulova

General characteristics of the job

Actuality of the topic The flour milling industry of Ukraine annually processes about 3.5 million tonnes of wheat, consuming 300…350 million kWh of electricity. At the same time, food and energy shortages are among the most important problems facing humanity today. In such circumstances, the rational use of grain based on resource and energy-saving technologies is a priority for the flour milling industry.

The high level of achievements in the theory and practice of grain processing is due to the works of scientists from Ukraine and neighbouring countries L.E. Aizykovych, V.V. Gortynsky, M.E. Ginzburg, V.Y. Hirshson, P.G. Demsky, I.R. Dudarev, G.A. Egorov, E.D. Kazakov, N.P. Kozmina, Vl. Kretovich, Y.N. Kupritz, A.V. Lykov, L.I. Lyubarsky, B.M. Maksymchuk, E.M. Melnikov, I.T. Merko, V.O. Morgun, I.A. Naumov, I.V. Romensky, P.P. Tarutin, L.A. Trisviatsky, S.D. Husid, as well as the works of foreign scientists Burdett, Fellers, Graf, Pfost, Krank, Bakshi, Becker, Kent, Morgan, Russ, Shepherd, Thorpe, Stenvert, Schmidt, Church and others.

The technical re-equipment of flour mills in the 80s and 90s of the last century made it possible to significantly increase the efficiency of flour production and potential processing capabilities by introducing advanced technologies. They were based on the implementation of the scientifically sound and practically proven principle of selective milling through the development of enrichment processes and differentiated effects on the product. Bühler’s 500 and 250 tonnes per day flour mills were distinguished by the maximum grain utilisation rate and high product quality, and formed the basis of the Soviet Union’s flour milling industry. However, the subsequent reforms of the national economy had a significant impact on their operation and the transformation of the flour milling industry. It turned out that in the new economic environment, technologies based on developed structures were too energy-intensive, requiring a large number of different machines and large production areas. In addition, other disadvantages typical of high-capacity production facilities were revealed: significant costs of material, labour and energy resources for centralising raw materials, distributing and selling finished products, high inertia in production processes and difficulty in responding quickly to sudden changes in market demand. The flour milling industry needed smaller, localised production facilities with lower set-up and operating costs. Flour mills based on reduced processing structures were and are being rapidly introduced in the country. Although they process about 30% of wheat grain, they only partially meet the requirements for flour quality and yield. Low utilisation of raw materials and low quality of products are in most cases insurmountable problems for these plants.

Therefore, the flour milling industry of Ukraine is currently represented by typical flour mills with a capacity of 500 and 250 tonnes per day, built 20…30 years ago, which have survived to this day without significant changes, implementing developed grinding structures, as well as new mills of lower capacity, both imported and domestic, implementing reduced grinding structures. The disadvantages inherent in the above mills indicate the lack of a sufficiently sound scientific base to enable effective improvement of flour production technologies.

To solve this problem, it is necessary to develop scientific foundations for improving the efficiency of varietal bread milling of wheat, as well as practical technological solutions for their implementation when creating new and reconstructing existing flour mills.

Correlation of work with scientific programmes, plans, topics. The dissertation was carried out in accordance with the scientific direction of the National University of Food Technologies “Development of the latest energy and resource-saving technologies” and the section “Development and improvement of technology of storage and processing of grain crops in order to obtain feed and food products of improved quality and assortment” (state registration number 012 u 0048861).

Aims and objectives of the research. The aim of the work is to develop scientific bases for improving the efficiency of varietal bakery wheat milling and the competitiveness of flour mills of different productivity.

The following tasks have been defined in accordance with the revenge objective:

- to substantiate the need to improve the technology of varietal bakery wheat milling;

- scientifically substantiate and select priority research areas;

- develop a comprehensive indicator for assessing the efficiency of grinding;

- justify technical and technological requirements for the means of implementing innovative technologies, develop and test ways to ensure them and evaluate their effectiveness;

- introduce the created innovative technologies into the industry, determine their practical value, technical and economic efficiency and test the baking properties of the flour produced;

- develop recommendations for the implementation of the proposed technologies and formulate directions for further development of technology and equipment for wheat grain processing.

Object of research – technologies for the production of wheat bakery varietal flour.

The subject of research is wheat grain, its processed products, and technological processes.

Research methods – generally accepted, technological, mathematical methods using modern devices and new computer technologies.

Scientific novelty of the results obtained. The trends have been identified, scientific provisions for improving the production technologies of wheat bakery varietal flour and technological equipment for their implementation have been formulated.

For the first time, the properties and features of the grain hulling technology using self-sharpening abrasive surfaces have been experimentally established.

For the first time, the regularities of grain cleaning technology in the process of hulling were established, the hygroscopic properties of hulled grain with hulling index values up to 8.0 %, as well as the features of groat formation during its grinding in different modes were determined.

The scientific substantiation and practical confirmation of the possibility and expediency of reducing the structure of varietal grinding of wheat at flour mills of different productivity due to the intensification of processing using grain hulling has been further developed.

The regularities of hulling technology are determined by changing the degree of loading of the working area of the equipment for processing the grain surface.

The possibility and expediency of intensifying the cold method of water-heat treatment (WHT) of grain due to its preliminary hulling has been proved.

The expediency of grain preparation for milling with a hulling index of 6…8 % is scientifically substantiated.

It has been proven that the implementation of wheat milling technology using hulling helps to attract the potential of the aleurone layer to increase the biological value of flour.

Practical significance of the results A comprehensive indicator of grinding efficiency has been developed and proposed for practical use.

Practical methods of implementing innovative technologies for varietal bread milling of wheat aimed at energy saving and rational use of raw materials by intensifying processes and reducing processing structures have been developed.

The article develops and proposes the complex and differentiated use of technological processes of grinding and sieving in the systems of grinding shell products according to the structure: roller mill – dismemberer – grinding machine – sieving and dismemberer – sieving.

The technological parameters of the means of implementing intensive technologies in reduced grinding structures are determined.

The structure and technological modes of grinding for new flour mills of different productivity, as well as for existing flour mills using complete equipment, when they are reconstructed according to several options relevant in the industry, are determined. For the practical implementation of the proposed technological solutions, we have developed the relevant technological schemes.

The feasibility study of the proposed technologies showed their significant advantage over the existing ones. The new flour production technologies provide the required level of its baking properties, which is necessary for the production of high quality bakery products.

The results obtained in the course of this work, in the form of new and improved machines, technological modes, operations, mills and technologies, have been implemented and successfully used at more than 20 flour mills in Ukraine and Russia.

The practical results of this work, namely the technological schemes of modular flour mills of various capacities, are recommended for use in the educational process when performing course and diploma projects in the speciality “Technology of grain storage and processing.”

The applicant’s personal contribution is to develop the basic concept of the work, select and justify the topic, develop research methods, conduct analytical and experimental studies in laboratory and production conditions, as well as develop the proposed innovative technologies. The analysis and generalisation of the research results was carried out together with the scientific adviser, Doctor of Technical Sciences, Professor Dmytruk E.A. In the materials published in co-authorship with colleagues and used in the dissertation, the applicant is responsible for the management of research and generalisation of their results.

Approbation of the results of the dissertation. The results of the work were presented at the 77th International Scientific Conference of Students, Postgraduates and Young Scientists (NUFT, Kyiv, 2010), XI International Scientific and Practical Conference “Bakery-2011” (ONAFT, Odesa, 2011), XII International Scientific and Practical Conference “Bakery-2012” (ONAFT, Odesa, 2012), International Scientific and Practical Conference “Advanced Techniques and Technologies of Food Production, Restaurant and Hotel Business and Trade. Economic Strategy and Prospects for the Development of Trade and Services” (Kharkiv State University of Food Technology, Kharkiv, 2012), International Scientific and Practical Internet Conference “Innovative Technologies in the Food Industry and Restaurant Business” (Kharkiv State University of Food Technology, Kharkiv, 2012), 79th International Scientific Conference of Students, Postgraduates and Young Scientists (NUFT, Kyiv, 2013)

Publications. Based on the materials of the dissertation, 33 works were published, including 24 articles in professional journals, 4 abstracts of scientific conferences, 2 patents for inventions, 3 patents for utility models.

Structure and scope of the thesis. The dissertation consists of an introduction, 6 chapters, general conclusions, a list of references of 331 items (33 pages), including 35 foreign authors, and 10 appendices (76 pages). The work is presented on 273 pages, including 58 figures (40 pages) and 63 tables (59 pages).

FOCUS OF WORK</strong

In the first section</strong “Current state, efficiency and development trends of wheat varietal bakery milling” describes the structural features and physical and mechanical properties of wheat grain, production processes and modern technological equipment for their implementation, the level of food use of wheat grain and the quality of flour produced from it, as well as analyses the existing technologies for the production of wheat bakery varietal flour and their efficiency indicators.

The article highlights that the nature of wheat grain determines a number of basic principles for ensuring its efficient processing into bakery flour, which include: consistent release of grain from the hulls with subsequent grinding; increasing the water absorption capacity of the grain and the rate of moisture penetration into the endosperm; selective grinding based on the difference in strength of the grain and its anatomical parts; improving the milling properties of fine grain.

It is noted that technological processes of flour production and equipment for their implementation are represented by a wide variety, which is due to their low overall efficiency in modern technologies. The current level of development of technological processes and equipment does not fully implement the basic principles of ensuring efficient processing of wheat grain into bakery flour.

It has been established that traditional technologies for the production of bakery flour aimed at ensuring the quality of flour in terms of ash content, a significant part of the nutritionally valuable substances that are part of a number of anatomical parts of the grain are directed to the bran. Compared to whole grains, varietal flour has a reduced nutritional value. Assessment of flour quality by whiteness, compared to ash content, more accurately characterises the consumer properties of flour and opens up the possibility of using the potential of the biological value of the aleurone layer.

It has been determined that currently there is no single indicator that allows for a reliable assessment of the technological efficiency of varietal grinding, and this complicates the assessment of their economic efficiency as a more generalised one. Taking into account the complex nature of grain and its processing processes, it is assumed that the solution to this problem is possible through a comprehensive technical and economic assessment of the efficiency of milling.

It has been established that technologies of varietal bakery wheat milling with developed structures provide a high degree of grain utilisation, but their implementation is associated with significant energy and other resources for the creation and operation of production facilities. Reducing the structure by intensifying the processing processes saves energy and resources and is in line with global trends in the development of wheat milling. However, the current technologies do not include methods to intensify the processes of bakery wheat milling, which can reduce their structures without reducing the degree of grain utilisation.

It has been determined that one of the most priority ways to improve the technologies of varietal bread milling of wheat should be considered the development and implementation of methods of process intensification and reduction of structures, which take into account the main principles of ensuring their efficiency.

In the second section “Research programme for improvement of technologies of varietal bread milling wheat”, as a result of selection and justification of priority research areas, the following scientific hypotheses were formulated:

.

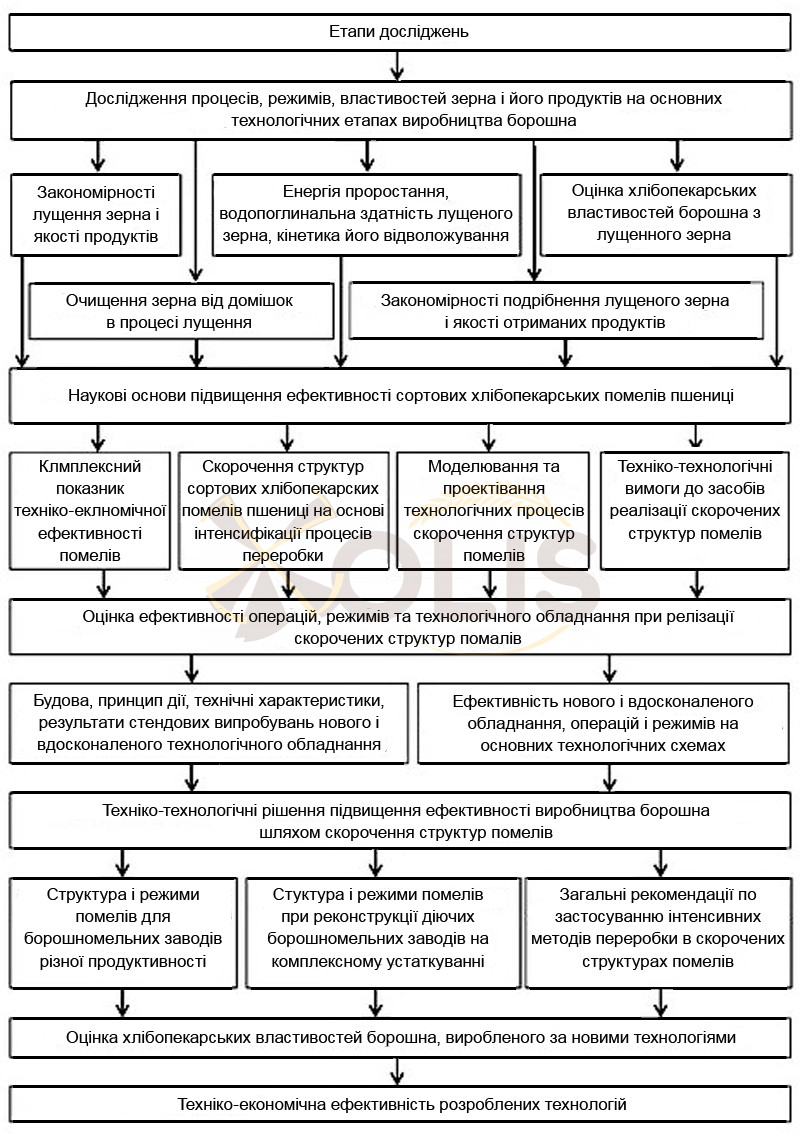

Taking into account the hypotheses, the goal and objectives of the research outlined earlier were formulated, and a research programme was developed, which includes a number of stages of implementation (Fig. 1).

The research programme was carried out using standard methods for determining the quality of grain and its products, as well as specially developed methods for: studying the grain hulling technology; assessing the efficiency of grain cleaning as a result of hulling; assessing the viability of hulled grain, its water absorption capacity and kinetics of its dehydration; assessing the efficiency of hulled grain milling; studying the baking properties of flour made from hulled grain. The implementation of special methods was carried out with the help of the developed and manufactured necessary laboratory equipment: a golendr, an aspirator and a rolling machine. In order to ensure the reliability and objectivity of the research results, the methods of mathematical and statistical processing of the experimental results were chosen.

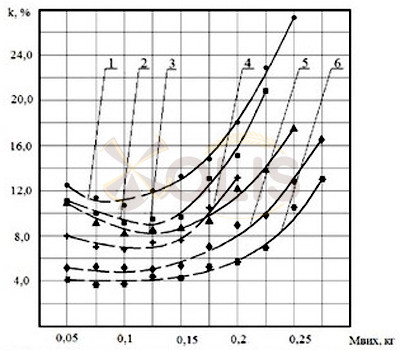

Fig. 2. Graphs of the dependence of the peeling index k on the mass of the initial sample Mвых during the treatment time t = 100 s:

– F46 14A SM1, Vp = 17 m/s, W = 12.4%;

– F46 14A SM1, Vp – 17 m/s, W = 16.9%;

– F60 25A SM1, Vp = 17 m/s, W = 12.4 %;

– F60 25A SM1, Vp = 17 m/s, W = 16.9 %;

– F46 14A SM1, Vp = 11 m/s, W = 12.4 %;

– F60 14A SM1, Vp = 11 m/s, W = 12.4 %.

The third chapter “Research of grain preparation and milling technology” presents the results of experimental studies that confirm the validity of the hypotheses put forward, as well as the necessary data for further theoretical substantiation and practical implementation of innovative methods to improve the efficiency of varietal bread milling of wheat.

As a result of studying the peeling technology, it was found that the interaction of grain with the abrasive rotor of peeling and grinding machines is characterised by several modes that differ in peeling efficiency (Fig. 2).

The limits of existence of the identified modes depend on many factors, such as the characteristics of the abrasive material of the abrasive rotor, its circular speed Vp, grain moisture content W, etc., but in any case are determined by the degree of filling of the working area of the machine, which, when processing grain in a laboratory hollander, is modelled by the mass of the initial sample Mv<//sub>. The part of each curve (Fig. 2) marked with an interrupted line reflects an inefficient hulling mode, which is characterised by low hulling intensity and uneven surface treatment of the grains, some of which are damaged at the ends or crushed. The areas marked with a solid line correspond to the effective hulling mode. This mode is characterised by a sharp increase in the intensity of hulling and uniformity of grain surface treatment, while their damage is reduced to insignificant values. The endpoints of the curves correspond to the maximum possible values of Mv of the effective peeling mode range, followed by emergency rotor jamming.

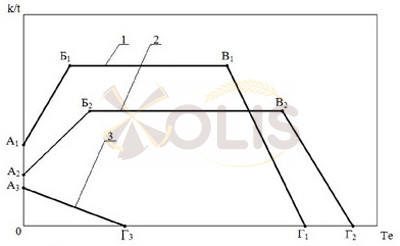

Fig. 3. Graphs of dependence of the peeling intensity k/t on the service life of grinding wheels Те with different self-sharpening intensity IC:

1 – IC1; 2 – IC2; 3 – IC3; IC1 > IC2 > IC3.

It has been established that the nature of the interaction between the grain and the working surface of the abrasive rotor of huskers is determined by agglomerates of grinding grains that create macro-roughness of the abrasive surface as a result of self-sharpening, which is the main feature of the grinding wheels operation during grain hulling. Observations have shown (Fig. 3) that during self-sharpening over a certain period (the period of increasing performance), the working surfaces of newly ground wheels gradually acquire macro-roughness (AB segments), which reaches its maximum values and is determined by the operating conditions of the wheels. These changes are accompanied by an increase in the intensity of peeling, reaching its maximum value and its stability over a long period of operation (sections BB). The period of stable operation of the wheels ends with a period of reduced performance and its complete loss as a result of wear, which is characterised by a change in the initial profile of the working surfaces of the wheels and a decrease in their outer diameter to critical values (segments BG). Diagram 3 is typical of grinding discs that are not subjected to self-sharpening conditions.

It has been established that the duration of the above periods, the service life and performance of grinding wheels depend on the intensity of the self-sharpening process. These properties of grinding discs are determined by their hardness and grit, and also depend on the grade of the abrasive grain. Discs with a lower hardness and coarser grit size and abrasive grain grades 54C and 64C are characterised by a higher abrasion rate and drive power consumption. This is due to the development of macro-roughness on their working surface as a result of self-sharpening and is explained by the lower bonding strength of the abrasive grains. In addition, abrasive grains of grades 54C and 64C are harder than grains 14A and 25A and have more developed and sharper ends, so their agglomerates retain high cutting performance over long periods of work.

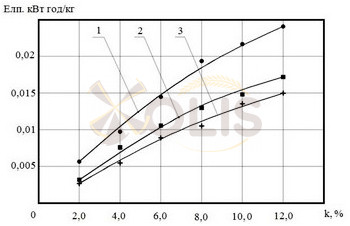

In continuous machines, the degree of filling of the working area is an operationally adjustable technological parameter used to establish quantitative and qualitative indicators of the peeling operation during the performance of production tasks. It has been established that an increase in the degree of filling of the working area (Figs. 4 and 5) leads to an increase in the intensity of peeling and also causes a significant increase in specific energy losses Elp.

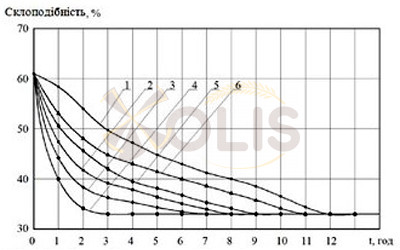

Fig. 4. Graphs of dependences of the peeling index k on the peeling duration t:

Grade of abrasive material 14A F60 SM1; Vp = 11.0 m/s.

1 – Mweights = 0.25 kg, 2 – Mweights = 0.225 kg, 3 – Mweights = 0.2 kg

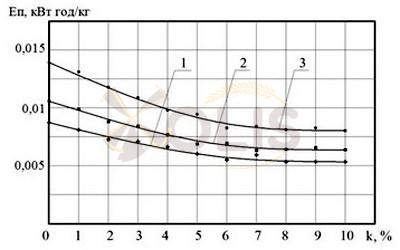

Fig. 5. Graphs of dependences of specific consumption of peeling energy Elp on peeling index k:

Grade of abrasive material 14A F60 SM1; Vp = 11.0 m/s.

1 – Mweights = 0.25 kg, 2 – Mweights = 0.225 kg, 3 – Mweights = 0.2 kg

The energy consumption of peeling operations in machines with abrasive rotors, in addition to the degree of filling of the working area, depends on many other factors and varies within a fairly wide range. The use of grinding wheels with a high self-sharpening rate, sieve plates with increased roughness, and an increase in the circumferential speed of the abrasive rotor leads to an intensification of peeling operations and a reduction in their energy consumption. With an increase in the distance between the abrasive rotor and the sieve shell, as well as grain moisture content, the intensity of hulling operations decreases and the energy consumption increases.

It has been determined that in the effective peeling mode, the only significant factor that determines the quality indicators of peeling products is the value of the peeling index k (Fig. 6). This is due to the absence of rigid contact of the working surface of grinding wheels with grains that are in a fluidised state during processing and the strength of their interaction, which is limited by the value of the intergranular pressure. Taking into account the implementation of the peeling technology and the quality of the products obtained, ensuring a rational peeling intensity and interrelated service life of grinding discs is a sufficient condition for selecting their material characteristics.

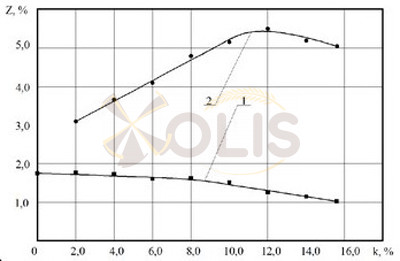

Fig. 6. Graphs of ash content of peeling products z versus peeling index k:

Grade of abrasive material for 14A F60 CM1 discs;

Vp = 11.0 m/s; Mw = 0.25 kg;

1 – grain; 2 – shells.

Fig. 7. Graphs of dependence of grain cleaning efficiency E on hulling index k:

1 – sieve shell with 1.3×12 mm meshes;

2 – a sieve shell with 0 2 mm holes.

● – debris; ■ – grain impurity

The technological efficiency of grain cleaning from impurities during hulling is proportional to its hulling index k. Grain processing with k-index values of more than 2.5 % in terms of the efficiency of removing weed impurities and with values of more than 3.5 % in terms of removing grain impurities exceeds the maximum possible efficiency of sieve-air cleaning (55 % and 32 %), in particular due to the separation of impurities that are difficult to separate (Fig. 7).

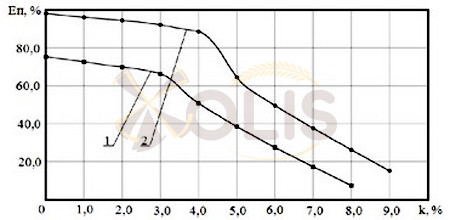

Wheat grain processing with a hulling index of more than 3.0% leads to a sharp decrease in grain viability (Fig. 8) and active development of mould fungi on the surface of its grains under conditions of high humidity.

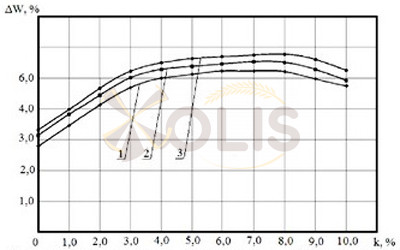

Pre-hulling of wheat grain with a hulling index of 3 % or more doubles the increase in grain moisture content during its moistening compared to non-hulled grain (Fig. 9).

Fig. 8. Graphs of dependences of germination energy Ep</sub

from the peeling index k:

The initial sample 1 – Ep = 75.0%; 2 – Ep = 98.0%.

Fig. 9. Graphs of the dependence of the increase in grain moisture ΔW on the hulling index k:

Duration of immersion in water 1 – 10 s; 2 – 20 s; 3 – 30 s.

The original sample W = 12.9 %

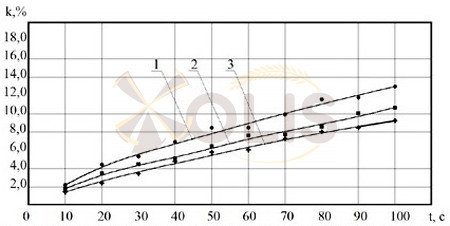

The rate of moisture spreading into the endosperm of hulled grain is determined by its hulling index and within k = 3…5 % reaches maximum values that are several times higher than the rate of moisture spreading into the endosperm of non-hulled grain (Fig. 10).

When hulled grain is milled, the quality of intermediate products is significantly improved, and the amount of coarse and medium grit increases (Table 1). The energy intensity of hulled grain grinding is on average 30…50% lower than that of non-hulled grain (Fig. 11).

Fig. 10. Graph of changes in grain vitreous depending on the duration of moistening t:

1 – k = 0 %; 2 – k = 1.5 %; 3 – k = 3.1 %;

4 – k = 5.1 %; 5 – k = 7.4 %; 6 – k = 8.9 %

Fig. 11. Graphs of dependence of specific grinding energy Ep on peeling index k on the selected system:

1 – total product of 40 %; 2 – total product of 50 %;

3 – the total product is 60 %

Table 1. Quantitative and qualitative indicators of grain grinding products on the dry system (quantity, % / ash content, %)

| Total product, % | Torment , % | 1000 мкм, % | Kr. cr., % | Wed. cr., % | Dr. cr., % | Dunst, % | Flour, % |

| 30 / 0,84 | 0 | 70 / 1,97 | 13,35 / 1,27 | 4,68 / 0,95 | 6,03 / 0,71 | 1,93 / 0,67 | 4,3 / 0,74 |

| 40 / 0,94 | 0 | 60 / 2,09 | 15,60 / 1,09 | 6,30 / 0,96 | 8,00 / 0,71 | 2,10 / 0,64 | 4,9 / 0,68 |

| 50 / 1,01 | 0 | 50 / 2,25 | 15,10 / 1,28 | 9,40 / 0,78 | 4,20 / 0,67 | 9,2 / 0,64 | |

| 60 / 0,98 | 0 | 40 / 2,60 | 19,10 / 1,91 | 11,20 / 0,79 | 13,90 / 0,60 | 4,70 / 0,56 | 11,5 / 0,59 |

| 70 / 1,29 | 0 | 30 / 3,01 | 16,50 / 2,12 | 13,60 / 0,85 | 18,10 / 0,61 | 5,80 / 0,57 | 14,9 / 0,57 |

| 30 / 0,97 | 4,0 / 4,42 | 66 / 1,68 | 13,80 / 1,17 | 4,90 / 0,92 | 5,50 / 0,79 | 1,90 / 0,66 | 3,4 / 0,88 |

| 40 / 0,89 | 4,0 / 4,42 | 56 / 1,78 | 18,90 / 1,00 | 6,50 / 0,87 | 7,50 / 0,71 | 2,70 / 0,59 | 5,2 / 0,85 |

| 50 / 1,09 | 4,0 / 4,42 | 46 / 2,04 | 19,76 / 1,25 | 12,90 / 1,15 | 9,70 / 0,79 | 3,20 / 0,66 | 6,9 / 0,81 |

| 60 / 1,12 | 4,0 / 4,42 | 36 / 2,33 | 24,60 / 1,54 | 12,00 / 0,85 | 13,20 / 0,76 | 4,10 / 0,61 | 9,5 / 0,71 |

| 70 / 1,18 | 4,0 / 4,42 | 26 / 2,81 | 20,10 / 2,14 | 15,20 / 0,99 | 18,80 / 0,69 | 5,70 / 0,57 | 13,7 / 0,65 |

| 30 / 0,88 | 8,0 / 5,02 | 62 / 1,54 | 14,70 / 1,01 | 4,50 / 0,83 | 5,00 / 0,73 | 1,90 / 0,57 | 3,6 / 0,92 |

| 40 / 0,94 | 8,0 / 5,02 | 52 / 1,73 | 21,20 / 0,98 | 6,40 / 0,92 | 6,90 / 0,75 | 2,5 / 0,67 | 5,0 / 0,89 |

| 50 / 0,92 | 8,0 / 5,02 | 42 / 2,05 | 25,50 / 1,05 | 8,70 / 0,79 | 8,90 / 0,68 | 3,10 / 0,61 | 6,0 / 0,76 |

| 60 / 0,86 | 8,0 / 5,02 | 32 / 2,15 | 26,70 / 1,09 | 11,20 / 0,73 | 11,20 / 0,62 | 3,60 / 0,58 | 7,3 / 0,75 |

| 70 / 0,95 | 8,0 / 5,02 | 22 / 2,70 | 22,00 / 1,52 | 15,30 / 0,78 | 17,00 / 0,67 | 5,00 / 0,59 | 10,8 / 0,67 |

The analysis of the chemical composition of flour showed that, when hulled grain is milled, there is an increase in the amount of aleurone layer entering the flour. Flour produced from hulled grain (Table 2) is characterised by improved whiteness and baking properties, which is confirmed by the results of trial laboratory baking.

Table 2: Quality indicators of flour with a yield of 70 % and bread made from it

| Peel index k, % | 0 | 3 | 6 | 8 |

| Ashiness, % | 0,62 | 0,63 | 0,65 | 0,59 |

| Whiteness, death unit R3-BPL | 58 | 58 | 59 | 60 |

| Protein content, % | 10,4 | 10,5 | 11,0 | 10,8 |

| Gluten content, % | 26 | 26 | 26 | 26 |

| Indicator of the VDK, um. unit | 55 | 55 | 55 | 55 |

| Fall number, p | 332 | 370 | 382 | 392 |

| Water absorption capacity, % | 57,4 | 57,9 | 59,6 | 59,2 |

| Fractional composition, % More 140 µm 140…125 µm 125…106 µm 106…95 µm Less 95 µm |

1 7 6 15 71 |

1 6 6 16 71 |

1 6 6 19 68 |

1 6 7 19 65 |

| Trial baking of bread: volumetric output, cm³ porosity, % |

382 73 |

392 74 |

418 77 |

416 77 |