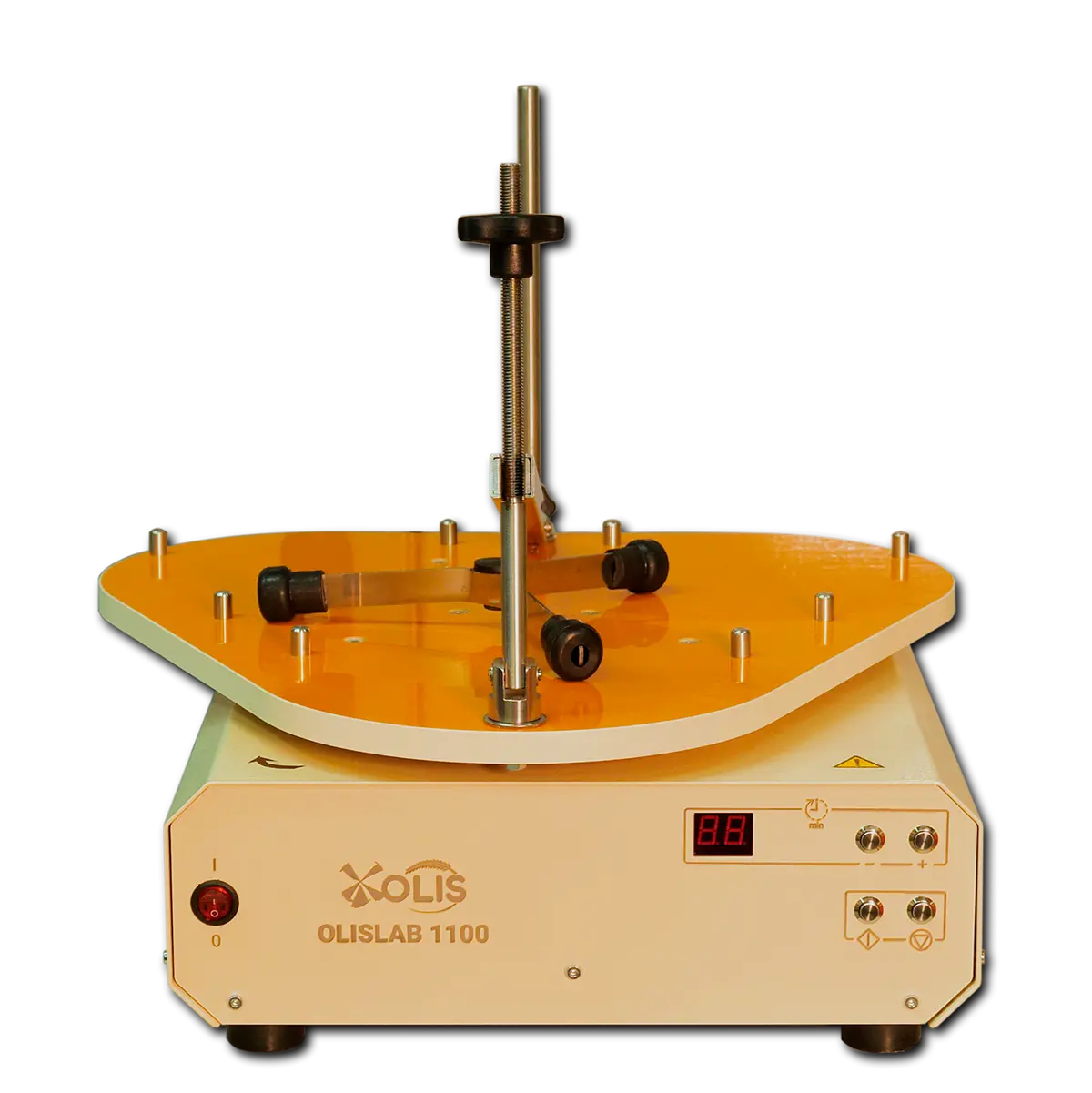

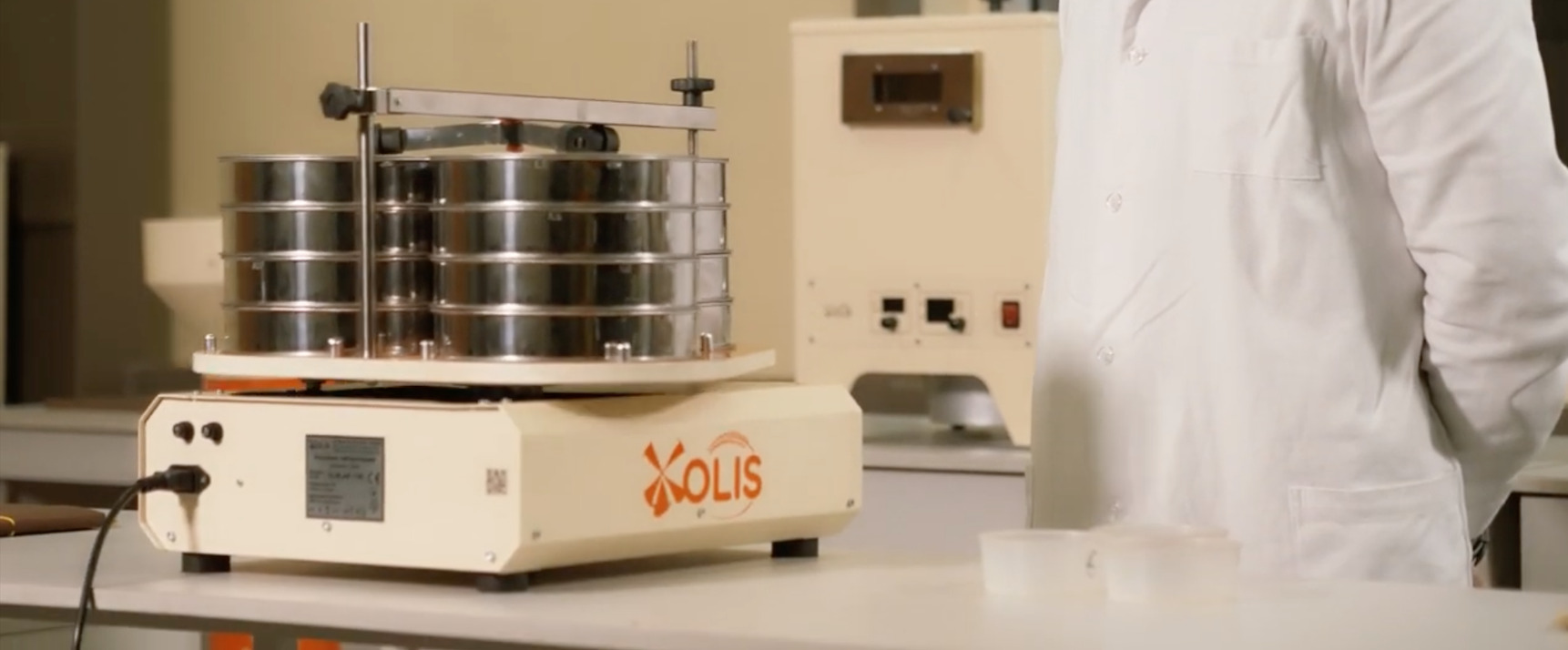

Laboratory Sifter OLISLAB 1100

Purpose and scope:

Laboratory sifter OLISLAB 1100 (universal, three-section), a modernized version of the sifter RLU-1, rotary type, designed for sorting (sifting) grain and products of its processing when determining contamination and infestation of grain; determining the fractional (granulometric) composition; controlling the fineness of flour, cereals, and animal feed; as well as controlling the size of the grinding of the sample in the process of sample preparation to analyze its quality.

With the help of the sifter, the sifting process is realized with a circular translational oscillation of the sieves in a horizontal plane.

It is used in grain receiving and grain processing enterprises, feed mills, oil extraction, bakery enterprises, variety testing breeding stations, research laboratories and inspection companies.

Scope of application: for standardized determination of infestation or contamination: of grain according to GOST 13586.4-83 (canceled in Ukraine), GOST 30483-97; of flour and bran according to GOST 27559-87 (canceled in Ukraine); size determination: of grain according to GOST 30483-97; of flour and bran according to GOST 27560-87 (canceled in Ukraine); of cereals according to GOST 26312.4-84 (canceled in Ukraine); determination of the crumbling of feed in accordance with GOST 28497-90 (canceled in Ukraine); as well as for use in other methods according to domestic and international standards.

Description:

The sifter consists of the body with the drive installed inside, the platform on which the sieve pack is placed, and a mechanism for fixing the sieves in the form of a rack, rods and a tee. On the front panel there is a scoreboard and control buttons for the device.

Sifting of bulk grain products is carried out through sieves that make circular translational oscillations in a horizontal plane, which is provided by a drive using three cranks. The design provides for the possibility of simultaneous sifting of three products on 4 sieves with 2 vibration modes of the sieve body: 120 vib/min. – for grain or sunflower; 200 vib/min. – for flour. The effective separation of products into fractions depends on the vibration frequency of the sieve body, the weight of the sample and the duration of sieving, set by the operator in accordance with the specified method for assessing the quality of grain and products of its processing.

Specifications

| Model | OLISLAB 1100 |

| Type | rotary |

| Sifting duration range, min | 0…99 |

| Number of sections, pcs. * | 1 / 3 |

| Number of sieves in a section, pcs. | 4 |

| Sieve diameter, mm | 300 / 200 |

| Number of kinematic modes | 2 |

| Sieve pack oscillation frequency, vib./min | 120 / 200 |

| Stability of oscillations in steady state, % | ±10 |

| Oscillation amplitude, mm | 50 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply, V / Hz | 230±23 / 50 |

| Pre-installed capacity, W | 15 |

| Overall dimensions L × D × H, | |

| in working condition, mm, not more | 485 × 470 × 485 |

| in transport condition, mm, not more | 540 × 530 × 200 |

| Weight without sieves net/gross, kg | 24 / 27 |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – air humidity, % | 60 ± 15 |

| * 3 sections – only for sieves ⌀ 200 mm | |

Аdvantages

MULTIPURPOSE

Can be used for:

– sorting (sifting) of grain and products of its processing in determining the contamination and infestation of grain;

– control of fineness of flour, cereals and feed;

– control of the grinding size of a grain sample in the process of sample preparation for further analysis of its quality indicators.

ERGONOMICS

Quick replacement of the sieve pack (by pressing the rod, without unscrewing the nut, disengage the folding rack from the rod).

Reliable, original sieve fixation system.

Highly visible display panel with countdown.

Main structural elements made of stainless steel.

VERSATILITY

Use of standard round sieves with a shell ⌀200 or ⌀300 mm.

Possibility to install 1 set of sieve packs with ⌀ 300 mm shell or simultaneously 3 sets of sieve packs with ⌀ 200 mm shell.

Possibility of using in two modes with the frequency of vibrations of the sieve package:

– 120 (vib/min) – for grain;

– 200 (vib/min) – for flour.

SAFETY AND DURABILITY

The resource of the device before the first average repair is 1000 hours.

The service life of the device is at least 10 years.

Photo

| Model | OLISLAB 1100 |

| Type | rotary |

| Sifting duration range, min | 0…99 |

| Number of sections, pcs. * | 1 / 3 |

| Number of sieves in a section, pcs. | 4 |

| Sieve diameter, mm | 300 / 200 |

| Number of kinematic modes | 2 |

| Sieve pack oscillation frequency, vib./min | 120 / 200 |

| Stability of oscillations in steady state, % | ±10 |

| Oscillation amplitude, mm | 50 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply, V / Hz | 230±23 / 50 |

| Pre-installed capacity, W | 15 |

| Overall dimensions L × D × H, | |

| in working condition, mm, not more | 485 × 470 × 485 |

| in transport condition, mm, not more | 540 × 530 × 200 |

| Weight without sieves net/gross, kg | 24 / 27 |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – air humidity, % | 60 ± 15 |

| * 3 sections – only for sieves ⌀ 200 mm | |

MULTIPURPOSE

Can be used for:

– sorting (sifting) of grain and products of its processing in determining the contamination and infestation of grain;

– control of fineness of flour, cereals and feed;

– control of the grinding size of a grain sample in the process of sample preparation for further analysis of its quality indicators.

ERGONOMICS

Quick replacement of the sieve pack (by pressing the rod, without unscrewing the nut, disengage the folding rack from the rod).

Reliable, original sieve fixation system.

Highly visible display panel with countdown.

Main structural elements made of stainless steel.

VERSATILITY

Use of standard round sieves with a shell ⌀200 or ⌀300 mm.

Possibility to install 1 set of sieve packs with ⌀ 300 mm shell or simultaneously 3 sets of sieve packs with ⌀ 200 mm shell.

Possibility of using in two modes with the frequency of vibrations of the sieve package:

– 120 (vib/min) – for grain;

– 200 (vib/min) – for flour.

SAFETY AND DURABILITY

The resource of the device before the first average repair is 1000 hours.

The service life of the device is at least 10 years.