Laboratory Oven MO-212

Purpose and scope:

Laboratory drying oven MO-212 (two-chamber) is designed to determine the moisture content in grain products, bulk materials and pasty substances.

The use of the MO series oven significantly improves the results of laboratories during interlaboratory tests on moisture analysis both according to DSTU and ISO standards. Also used to adjust and calibrate moisture meters and infrared analyzers.

Description:

The principle of operation is based on high-temperature dehydration of samples of the studied products (crushed grain, crushed seeds, flour, etc.) placed in oven cells.

When samples are heated, moisture evaporates, reducing the weight of the analyzed sample. The flow of air entering through the openings in the doors of the drying cabinet and the pipes in the back of the cabinet creates draft. The moisture evaporated from the product is removed by convection by hot air flow through pipes into the atmosphere. The control unit of the oven maintains a stable set temperature in each drying chamber, visually displayed on digital displays.

Model MO-212 has two independent drying chambers, in which different temperature conditions can be used, and 4 working sections (2 in each chamber).

Specifications

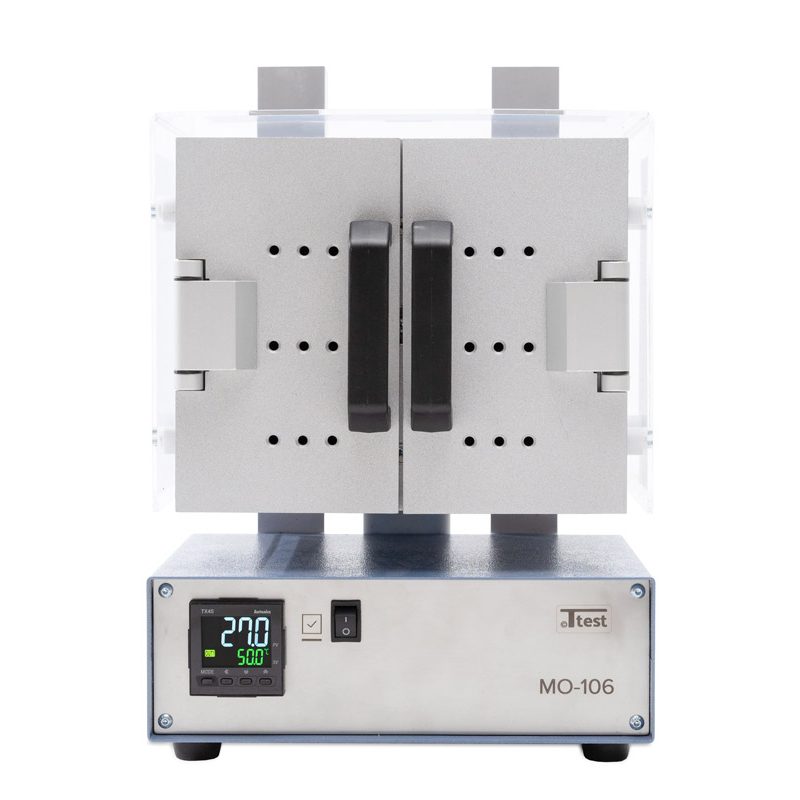

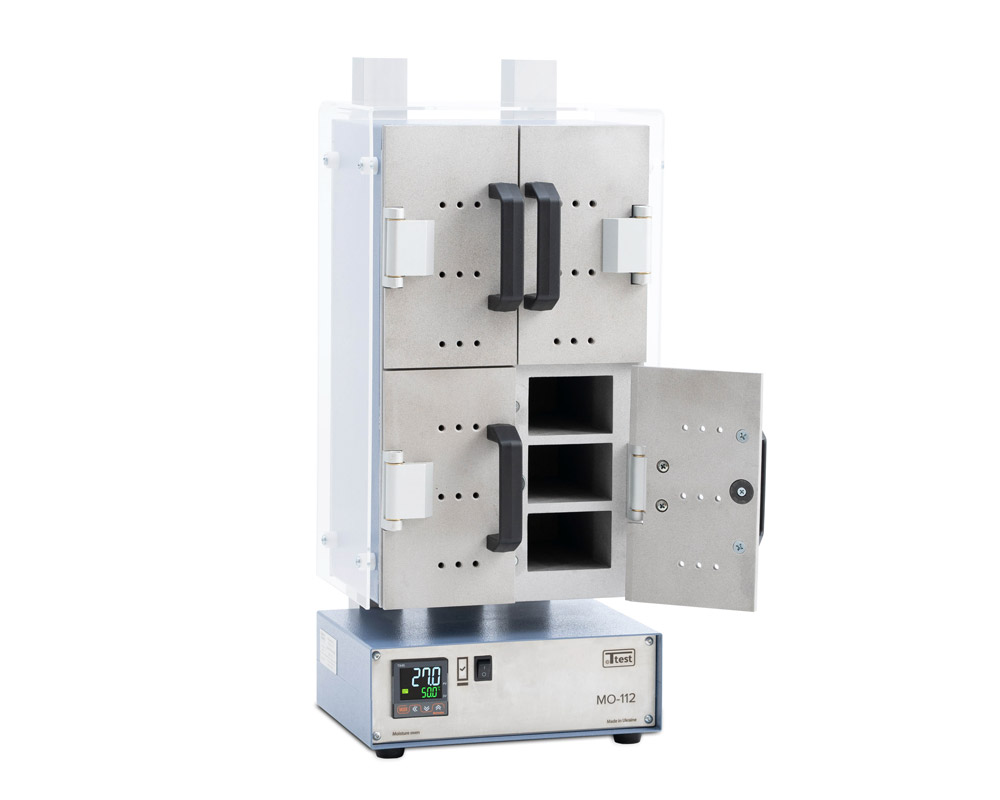

| Model | MO-106 | MO-112 | MO-212 |

| Type | electric, convective |

electric, convective |

electric, convective |

| Operating temperature range, ℃ | 40…160 | 40…160 | 40…160 |

| Temperature stability in steady state thermal conditions in the working area, ℃ | ± 2 | ± 2 | ± 2 |

| Number of operating chambers, pcs | 1 | 1 | 2 |

| Number of operating sections, pcs | 2 | 4 | 4 |

| Number of operating cells in the section, pcs | 3 | 3 | 3 |

| Operating cell size, mm | 75 × 40 × 155 | 75 × 50 × 155 | 75 × 40 × 155 |

| Maximum number of bottles ⌀ 50 mm, pcs | 12 | 24 | 24 |

| Power consumption, W | 600 | 1200 | 1200 |

| Dimensions L × W × H, mm | |||

| – in working condition, mm, not more | 261 × 260 × 370 | 260 × 260 × 580 | 260 × 260 × 580 |

| – in transport condition, mm, not more | 600 × 600 × 580 | 380 × 380 × 780 | 380 × 380 × 780 |

| Net/gross weight, kg | 14,5 / 19,0 | 24,5 / 28,0 | 24,0 / 27,0 |

Аdvantages

- Convenient access to the drying chamber cells

- Two independent drying chambers

- Stable temperature maintenance

- Reliability, stability and safety

- Silent operation

Photos

| Model | MO-106 | MO-112 | MO-212 |

| Type | electric, convective |

electric, convective |

electric, convective |

| Operating temperature range, ℃ | 40…160 | 40…160 | 40…160 |

| Temperature stability in steady state thermal conditions in the working area, ℃ | ± 2 | ± 2 | ± 2 |

| Number of operating chambers, pcs | 1 | 1 | 2 |

| Number of operating sections, pcs | 2 | 4 | 4 |

| Number of operating cells in the section, pcs | 3 | 3 | 3 |

| Operating cell size, mm | 75 × 40 × 155 | 75 × 50 × 155 | 75 × 40 × 155 |

| Maximum number of bottles ⌀ 50 mm, pcs | 12 | 24 | 24 |

| Power consumption, W | 600 | 1200 | 1200 |

| Dimensions L × W × H, mm | |||

| – in working condition, mm, not more | 261 × 260 × 370 | 260 × 260 × 580 | 260 × 260 × 580 |

| – in transport condition, mm, not more | 600 × 600 × 580 | 380 × 380 × 780 | 380 × 380 × 780 |

| Net/gross weight, kg | 14,5 / 19,0 | 24,5 / 28,0 | 24,0 / 27,0 |

- Convenient access to the drying chamber cells

- Two independent drying chambers

- Stable temperature maintenance

- Reliability, stability and safety

- Silent operation