Laboratory Oven OLISLAB 4100

Purpose and scope:

Drying oven OlisLab 4100 (electric), a modernized version of the oven SESh-3MU, with forced ventilation, is designed for drying products when determining moisture content of grain, grain products, legumes and oilseeds, as well as other moisture-containing substances, in accordance with domestic and international standards.

Using the device, a direct air-thermal method for determining the mass fraction of moisture is implemented, based on measuring the mass of the analyte sample before and after drying.

It is used at grain-receiving, grain processing, feed, oil extraction, bakery and other food enterprises, variety testing breeding stations, research laboratories and inspection companies.

Scope of application: for the standardized determination of moisture content by the air-thermal method: for grain according to GOST 13586.5; for oilseeds according to DSTU 4811:2007; for bakery products according to DSTU 7045:2009; for confectionery according to DSTU 4910:2008; as well as for use in other methods according to domestic and international standards.

Description:

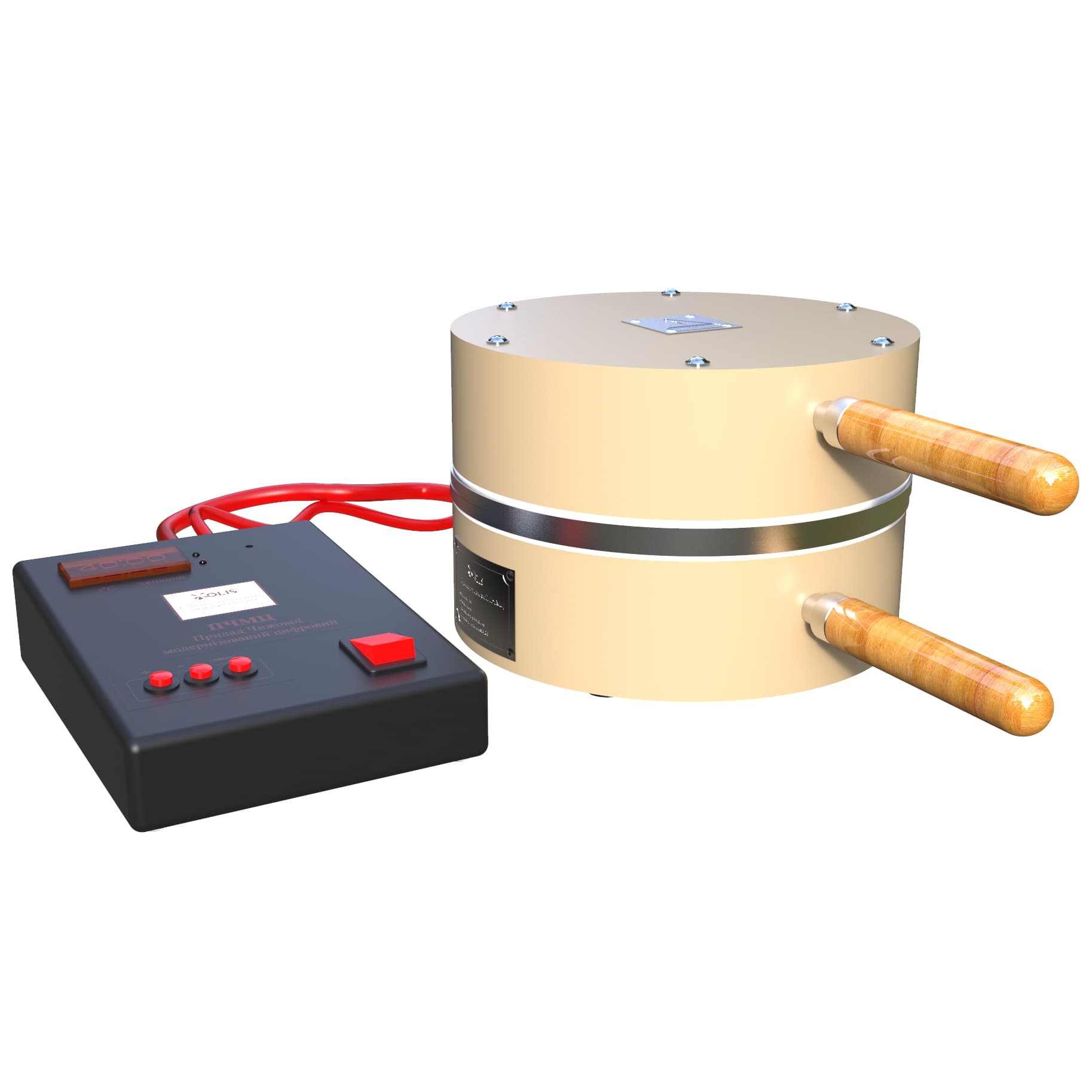

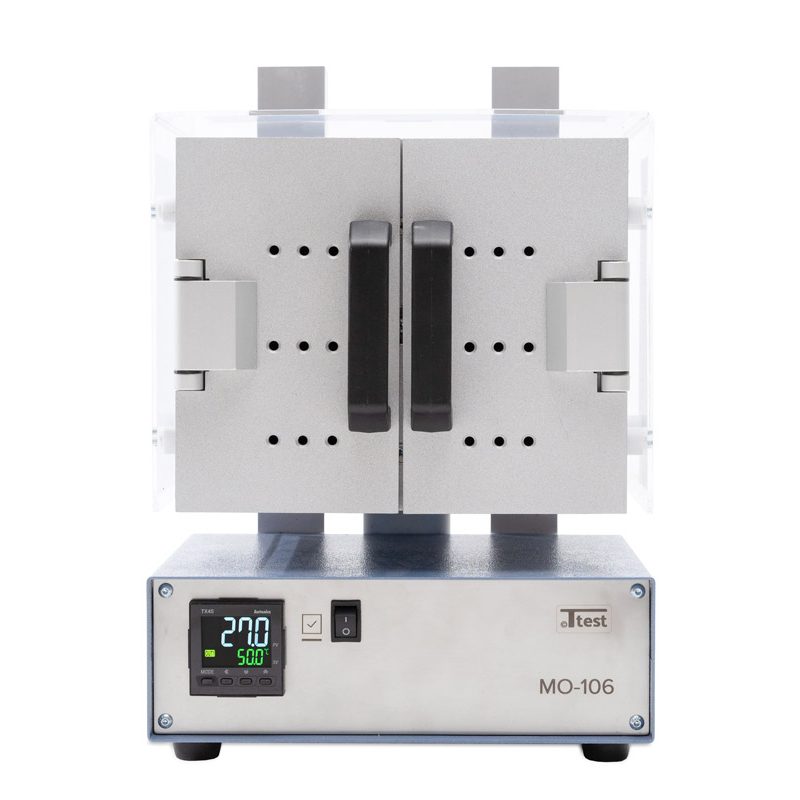

The drying oven consists of a body, a drying chamber with a door for loading bottles and a table rotating with the help of a geared motor, a fan, a heater, and a control unit with a display and measuring equipment.

The principle of operation of the drying oven is based on the uniform drying of samples of the studied products with hot air supplied to the drying chamber of the oven with a fan through an electric heating element heated to a predetermined temperature.

The drying oven is equipped with a table with cells for bottles, which constantly rotates for uniform heating of the product. The required temperature is set on the digital thermostat located on the front panel of the device.

Specifications

| Model | OLISLAB 4100 |

| Type | electric, forced ventilation |

| Nominal values of automatically controlled temperature in the working area, ℃ | 105; 130 |

| Temperature stability in steady state thermal conditions in the working area, ℃ | ± 2 |

| Temperature setting resolution, ℃ | 0,1 |

| Heating time up to +130 ℃ under specified operating conditions, min, not more | 15 |

| Temperature recovery time up to +130℃ after full sample loading, min, not more | 10 |

| Number of working chambers, pcs. | 1 |

| Maximum number of bottles ⌀ 50 mm, pcs. | 8 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply: voltage / frequency, V / Hz | 230±23 / 50 |

| Power consumption, W | 2000 |

| Dimensions L × W × H:, | |

| – in working condition, mm, not more | 360 × 360 × 520 |

| – in transport condition, mm, not more | 450 × 450 × 600 |

| Net/gross weight, kg | 23 / 25 |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – ambient temperature, % | 60 ± 15 |

Аdvantages

EFFECTIVENESS

Quick access to the drying mode both after turning on the device and after it is fully loaded with samples occurs due to the high power of the electric heater.

ERGONOMIC

Modern technical design.

Highly visible display panel.

ACCURACY

Temperature stability due to high-precision thermostats.

Uniformity of heating due to the rotating table during the operation of the cabinet.

Accompanied by a metrological calibration certificate.

VERSATILITY

Allows you to measure the moisture content in almost any product or material for which the air-thermal method is used.

It can be used to determine the moisture content of grain products by standard drying method (aluminum weighing bottles) and by drying with pre-drying (mesh weighing bottles).

SAFETY AND DURABILITY

Reduced noise level.

Overheating and restart protection.

High reliability of the product due to design features and the use of modern technological solutions.

Service life of the device is 10 years.

Photos

| Model | OLISLAB 4100 |

| Type | electric, forced ventilation |

| Nominal values of automatically controlled temperature in the working area, ℃ | 105; 130 |

| Temperature stability in steady state thermal conditions in the working area, ℃ | ± 2 |

| Temperature setting resolution, ℃ | 0,1 |

| Heating time up to +130 ℃ under specified operating conditions, min, not more | 15 |

| Temperature recovery time up to +130℃ after full sample loading, min, not more | 10 |

| Number of working chambers, pcs. | 1 |

| Maximum number of bottles ⌀ 50 mm, pcs. | 8 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply: voltage / frequency, V / Hz | 230±23 / 50 |

| Power consumption, W | 2000 |

| Dimensions L × W × H:, | |

| – in working condition, mm, not more | 360 × 360 × 520 |

| – in transport condition, mm, not more | 450 × 450 × 600 |

| Net/gross weight, kg | 23 / 25 |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – ambient temperature, % | 60 ± 15 |

EFFECTIVENESS

Quick access to the drying mode both after turning on the device and after it is fully loaded with samples occurs due to the high power of the electric heater.

ERGONOMIC

Modern technical design.

Highly visible display panel.

ACCURACY

Temperature stability due to high-precision thermostats.

Uniformity of heating due to the rotating table during the operation of the cabinet.

Accompanied by a metrological calibration certificate.

VERSATILITY

Allows you to measure the moisture content in almost any product or material for which the air-thermal method is used.

It can be used to determine the moisture content of grain products by standard drying method (aluminum weighing bottles) and by drying with pre-drying (mesh weighing bottles).

SAFETY AND DURABILITY

Reduced noise level.

Overheating and restart protection.

High reliability of the product due to design features and the use of modern technological solutions.

Service life of the device is 10 years.