Laboratory Oven OLISLAB 4200

Purpose and scope:

Drying oven OlisLab 4200 (electric), a modernized version of the oven OL-36, convective type, is designed for drying products when determining moisture content of grain, grain products, legumes and oilseeds, as well as other moisture-containing substances, in accordance with domestic and international standards.

Using the device, a direct air-thermal method for determining the mass fraction of moisture is implemented, based on measuring the mass of the analyte sample before and after drying.

It is used at grain-receiving, grain processing, feed, oil extraction, bakery and other food enterprises, variety testing breeding stations, research laboratories and inspection companies.

Scope of application: for the standardized determination of moisture content by the air-thermal method according to GOST 13586.5; DSTU 4811:2007; DSTU 7045:2009; DSTU 4910:2008; DSTU ISO 6540:2007; <br>ISO 712:2015 (ISO 712:2009, IDT); ISO 712:2009; ISO 6540:2021; ISO 24557:2009; ISO 6496:1999; AACC 44-15A; Gafta 2:1; Gafta 2:2; as well as for use in other methods according to domestic and international standards.

Description:

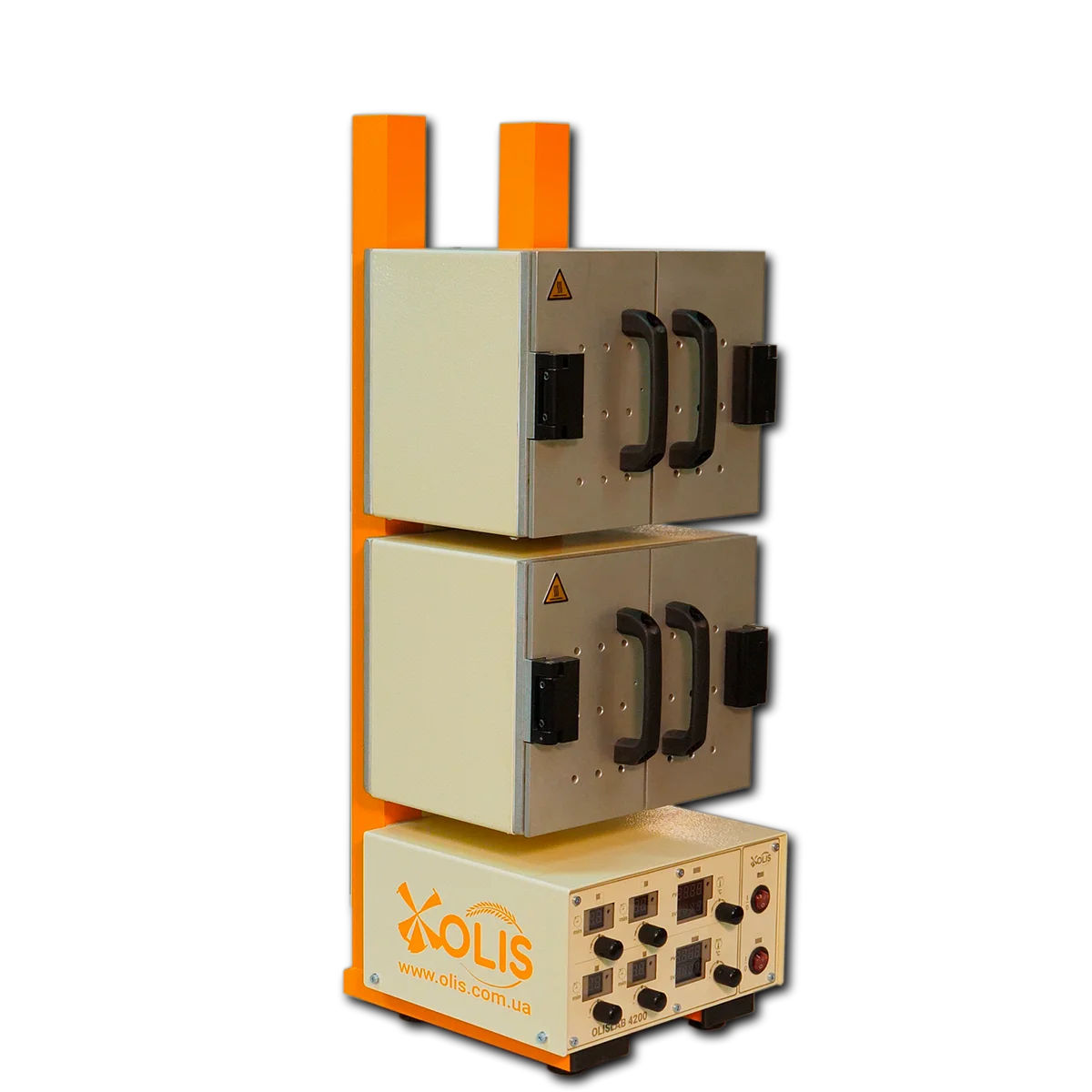

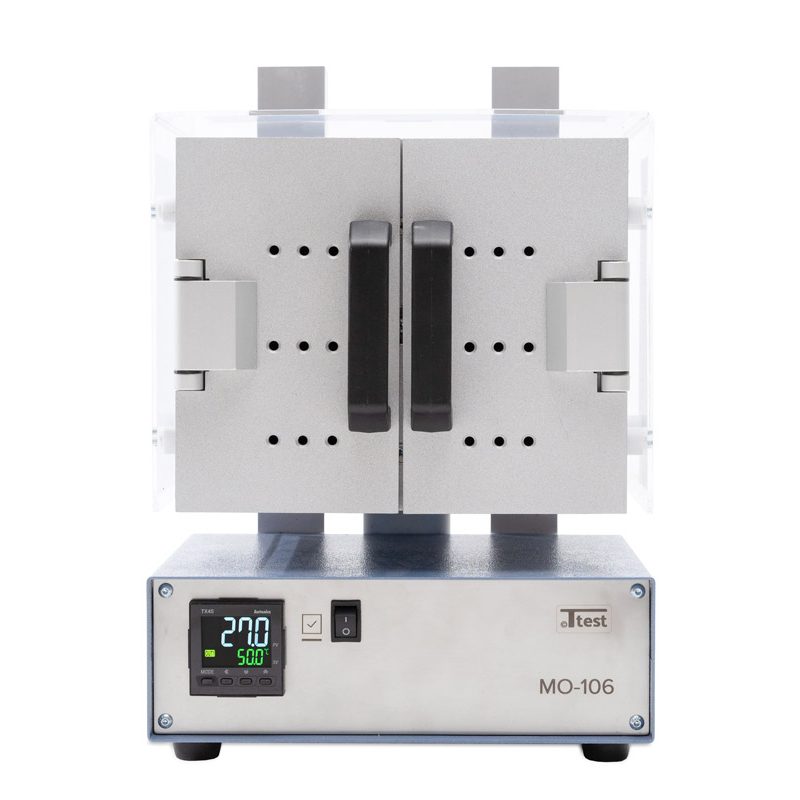

The device consists of two independent drying chambers and a temperature control unit and a drying time setting, interconnected by square exhaust pipes. Each drying chamber is divided into two sections (each section consists of three cells). The temperature of each chamber is maintained by a separate thermostat. The presence of two independent temperature controllers provides the possibility of setting different temperatures in the upper and lower chambers and carrying out independent measurements in two chambers at different temperatures.

The principle of operation of the drying oven is based on the convective drying of the studied samples as a result of the heat and mass transfer processes with the surface of the drying chamber heated to a predetermined temperature. The operating temperature in each drying chamber is created by electric heaters, which are located in the lower part of the oven, and high-precision thermostats provide a stable set temperature. When being in the zone of high temperature, the studied samples heat up, the moisture from them gradually disappears, and their weight decreases. The air flow passing through the openings in the door and the chimneys in the back of the case creates draft by convection, and the evaporated moisture is removed by a hot air stream through the chimneys to the atmosphere.

Specifications

| Model | OLISLAB 4200 |

| Type | electric, convective |

| Automatic temperature adjustment range, ℃ | 0…160 |

| Temperature stability in the steady state thermal regime in the working area, ℃ | ± 2 |

| Temperature setting resolution, ℃ | 0,1 |

| Heating time up to +130 ℃ under specified operating conditions, min, not more | 40 |

| Temperature recovery time up to +130℃ after full sample loading, min, not more | 15 |

| Range of set values for the drying time, min | 1…99 |

| Number of working chambers, pcs. | 2 |

| Number of working sections, pcs. | 4 |

| Number of working cells in the section, pcs. | 3 |

| Working cell size, mm | 78 × 40 × 160 |

| Maximum number of bottles ⌀ 50 mm, pcs. | 24 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply: voltage/frequency, V / Hz | 230±23 / 50 |

| Power consumption, W | 1200 |

| Габаритные размеры Д × Г × В, | |

| – in working order, mm, not more | 255 × 275 × 610 |

| – in transport condition, mm, not more | 720 × 430 × 445 |

| Net/gross weight, kg | 32,7 / 46,2 |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – relative humidity, % | 60 ± 15 |

Аdvantages

PRODUCTIVITY

2 independent working chambers with their own thermostats provide the possibility of independent measurements in two chambers at different temperatures with a maximum load of 24 bottles.

4 independent sections with their own timers allow 4 analyzes to be carried out simultaneously.

ERGONOMIC

Convenient loading and unloading bottles.

Audible alarm at the end of the drying time.

Contrasting display panel.

ACCURACY

Temperature stability.

Unloading/loading bottles of one section does not affect the results of analysis in other sections.

Accompanied by a metrological calibration certificate.

VERSATILITY

Allows you to measure moisture content in almost any product or material for which the air-thermal method is used.

SILENCE

Natural ventilation through convective heating ensures that there are no moving parts.

ENERGY EFFICIENCY

40% less energy consumption compared to a cabinet with forced ventilation.

SAFETY AND DURABILITY

Overheating and restart protection.

Resource of the device before the first average repair is 10 thousand hours.

Service life of the device is 10 years.

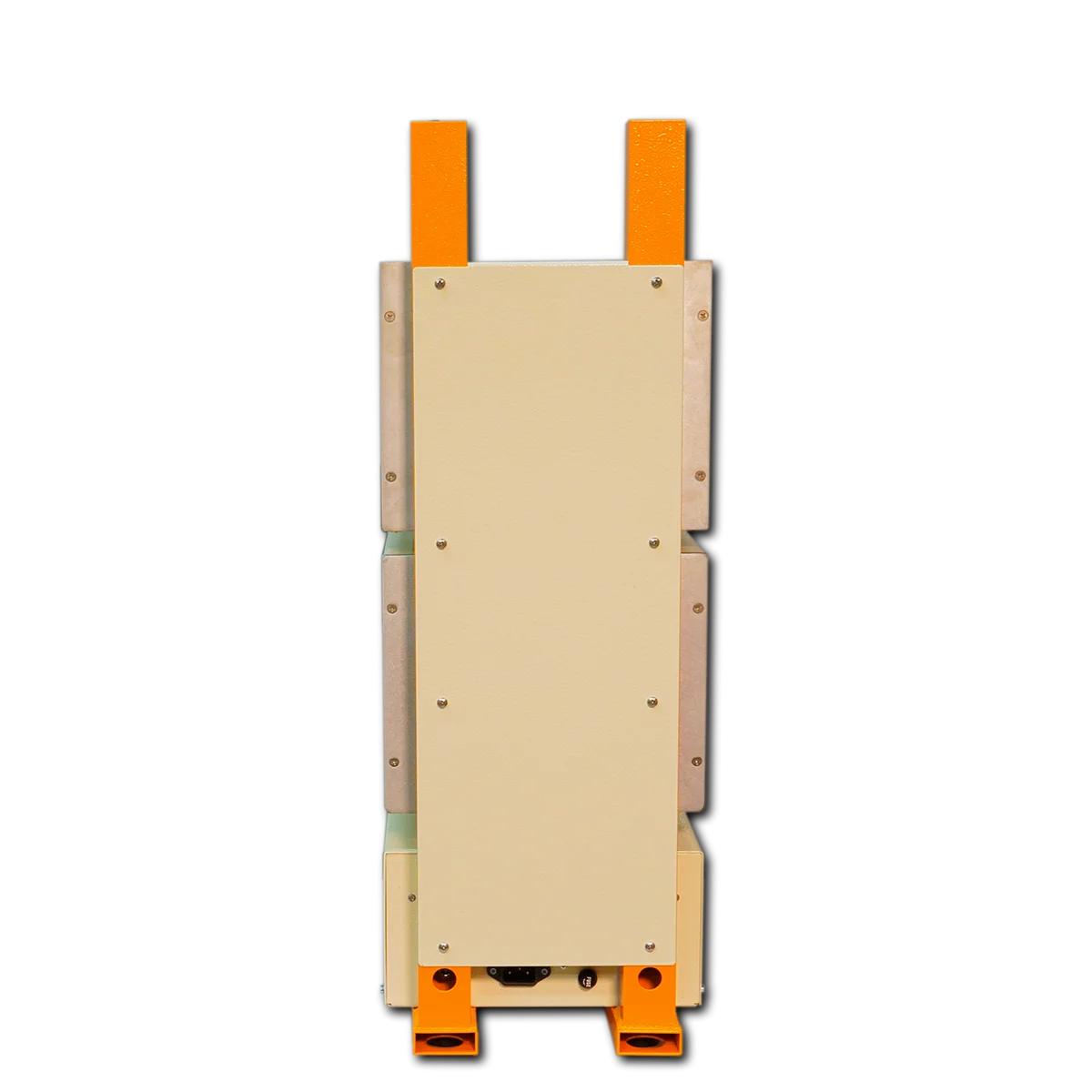

Photo

| Model | OLISLAB 4200 |

| Type | electric, convective |

| Automatic temperature adjustment range, ℃ | 0…160 |

| Temperature stability in the steady state thermal regime in the working area, ℃ | ± 2 |

| Temperature setting resolution, ℃ | 0,1 |

| Heating time up to +130 ℃ under specified operating conditions, min, not more | 40 |

| Temperature recovery time up to +130℃ after full sample loading, min, not more | 15 |

| Range of set values for the drying time, min | 1…99 |

| Number of working chambers, pcs. | 2 |

| Number of working sections, pcs. | 4 |

| Number of working cells in the section, pcs. | 3 |

| Working cell size, mm | 78 × 40 × 160 |

| Maximum number of bottles ⌀ 50 mm, pcs. | 24 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply: voltage/frequency, V / Hz | 230±23 / 50 |

| Power consumption, W | 1200 |

| Габаритные размеры Д × Г × В, | |

| – in working order, mm, not more | 255 × 275 × 610 |

| – in transport condition, mm, not more | 720 × 430 × 445 |

| Net/gross weight, kg | 32,7 / 46,2 |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – relative humidity, % | 60 ± 15 |

PRODUCTIVITY

2 independent working chambers with their own thermostats provide the possibility of independent measurements in two chambers at different temperatures with a maximum load of 24 bottles.

4 independent sections with their own timers allow 4 analyzes to be carried out simultaneously.

ERGONOMIC

Convenient loading and unloading bottles.

Audible alarm at the end of the drying time.

Contrasting display panel.

ACCURACY

Temperature stability.

Unloading/loading bottles of one section does not affect the results of analysis in other sections.

Accompanied by a metrological calibration certificate.

VERSATILITY

Allows you to measure moisture content in almost any product or material for which the air-thermal method is used.

SILENCE

Natural ventilation through convective heating ensures that there are no moving parts.

ENERGY EFFICIENCY

40% less energy consumption compared to a cabinet with forced ventilation.

SAFETY AND DURABILITY

Overheating and restart protection.

Resource of the device before the first average repair is 10 thousand hours.

Service life of the device is 10 years.