Laboratory Oven & Gluten Dryer OLISLAB 4300

“OLIS” LLC specializes in the development, production and implementation of technologies and equipment for grain cleaning, processing, transportation and quality control. Today, “OLIS” LLC is one of the largest manufacturers of Ukraine, which produces more than 200 types of equipment in this segment, including laboratory equipment.

Laboratory equipment for grain quality control plays a key role in ensuring product compliance with standards. It allows you to determine the content of moisture, proteins, gluten and other important indicators that affect the quality of the grain. Thanks to accurate analyses, it is possible to effectively control the process of storage and processing of grain products.

Purpose and scope of use:

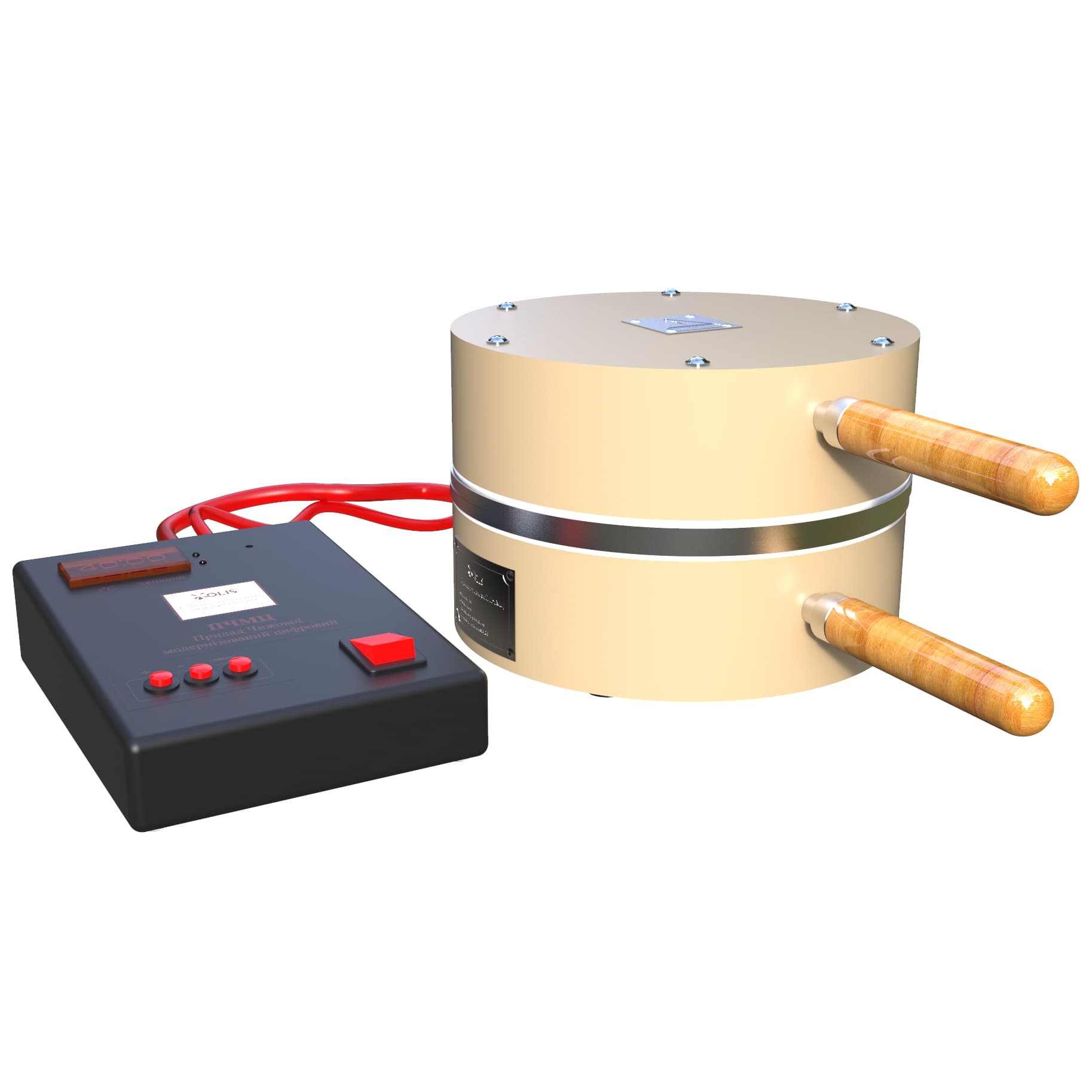

OlisLab 4300 drying oven (by Chizhova), a modernized version of the PChMC oven, designed for accelerated (express) determination and control of the moisture content of food raw materials, semi-finished products and finished products; as well as determination of dry gluten content.

With the help of this device a direct thermal method of determining the mass fraction of moisture or the content of dry gluten is implemented, which is based on the measurement of the mass of the sample of the analyzed substance before and after drying with subsequent calculation.

It is used in grain-receiving, grain-processing, bakery and other food enterprises, variety testing and selection stations, in research laboratories and inspection companies.

Scope of application

For the standardized determination of humidity by the direct thermal method (express method, on a contact drying hygrometer): bakery products according to DSTU 7045:2009; yeast according to DSTU 4812:2007; milk and dairy products according to DSTU 8552:2015; dry gluten content according to DSTU ISO 6645:2004 and ISO 21415-4:2006; as well as for use in other methods according to domestic and international standards.

Description

The device consists of a sample drying unit and an electronic control and monitoring unit. The drying unit consists of upper and lower heating plates connected by a loop. The electronic control and control unit consists of a temperature regulation and control unit and a drying duration assignment unit.

The principle of operation of the drying oven is based on the drying of the tested samples by direct heating between plates heated to a given temperature. The speed of the analysis is ensured by the high temperature of the plates and the close contact of their surfaces with the product, which is provided by the high compressive force due to the massive design of the heating plates and the possibility of adjusting the gap between them.

Setting and automatically maintaining the required temperature, setting the duration of drying and visual control of these parameters is carried out using an electronic control unit equipped with a digital indicator.

Specifications

| Model | OLISLAB 4300 |

| Type | with metal surface / with non-stick surface |

| Automatic temperature adjustment range, ℃ | 50…199 |

| Temperature stability in steady state thermal conditions in the working area, ℃ | ± 2 |

| Temperature setting resolution, ℃ | 0,1 |

| Heating time up to +160 ℃ under specified operating conditions, min, not more | 30 |

| Range of set values for the drying time, min | 1…99 |

| Adjustable gap between the working surfaces of the plates (without samples), mm | 0,1…10 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply: voltage / frequency, V / Hz | 230±23 / 50 |

| Power consumption, W | 700 |

| Dimensions L × D × H, | |

| – drying block, mm, not more | 345 × 220 × 170 |

| – control unit, mm, not more | 185 × 160 × 65 |

| – in transport condition, mm, not more | 450 × 230 × 250 |

| Net/gross weight, kg | 8,5 / 10,0 |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – relative humidity, % | 60 ± 15 |

Аdvantages

Operability:

- Quick determination of the result due to high-temperature heating between the contact heating plates.

Ergonomics:

- Original technical design.

- Audible alarm at the end of the drying time.

- A clearly visible indicator panel with a countdown timer.

Stability of results:

- Temperature stability due to high-precision thermostats.

- Uniform heating of the product due to the massive construction of contact heating plates.

- Accompanied by a certificate of metrological calibration.

Versatility:

- Allows you to control the moisture content of almost any moisture-containing food product.

- It can be used both for the express determination of moisture content and the content of dry gluten, and for technological purposes (for example, for the preparation of wafer sheets).

Safety and Durability:

- Overheating and restart protection.

- Thermal insulation of the body of the drying unit.

- The service life of the device is 10 years.

Advantages of ordering on the olis.com.ua website

Order laboratory equipment of “OLIS” LLC is conveniently located on our premises site, you get the following benefits:

Convenience and time saving.

On the site you can:

- quickly find the necessary model of laboratory equipment;

- view video views and customer reviews that bought our products;

- familiarize yourself with the technical characteristics, the principle of operation;

- compare different options and prices.

Quality assurance and consultation.

By communicating with our managers, you will be able to:

- get detailed information about laboratory equipment;

- choose the best equipment model according to your needs cost.

Service and warranty service.

We provide:

- a full range of service services in accordance with technical regulations;

- warranty and post-warranty service.

Read more about the service on the page service maintenance.

Photo

| Model | OLISLAB 4300 |

| Type | with metal surface / with non-stick surface |

| Automatic temperature adjustment range, ℃ | 50…199 |

| Temperature stability in steady state thermal conditions in the working area, ℃ | ± 2 |

| Temperature setting resolution, ℃ | 0,1 |

| Heating time up to +160 ℃ under specified operating conditions, min, not more | 30 |

| Range of set values for the drying time, min | 1…99 |

| Adjustable gap between the working surfaces of the plates (without samples), mm | 0,1…10 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply: voltage / frequency, V / Hz | 230±23 / 50 |

| Power consumption, W | 700 |

| Dimensions L × D × H, | |

| – drying block, mm, not more | 345 × 220 × 170 |

| – control unit, mm, not more | 185 × 160 × 65 |

| – in transport condition, mm, not more | 450 × 230 × 250 |

| Net/gross weight, kg | 8,5 / 10,0 |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – relative humidity, % | 60 ± 15 |

Operability:

- Quick determination of the result due to high-temperature heating between the contact heating plates.

Ergonomics:

- Original technical design.

- Audible alarm at the end of the drying time.

- A clearly visible indicator panel with a countdown timer.

Stability of results:

- Temperature stability due to high-precision thermostats.

- Uniform heating of the product due to the massive construction of contact heating plates.

- Accompanied by a certificate of metrological calibration.

Versatility:

- Allows you to control the moisture content of almost any moisture-containing food product.

- It can be used both for the express determination of moisture content and the content of dry gluten, and for technological purposes (for example, for the preparation of wafer sheets).

Safety and Durability:

- Overheating and restart protection.

- Thermal insulation of the body of the drying unit.

- The service life of the device is 10 years.

Advantages of ordering on the olis.com.ua website

Order laboratory equipment of “OLIS” LLC is conveniently located on our premises site, you get the following benefits:

Convenience and time saving.

On the site you can:

- quickly find the necessary model of laboratory equipment;

- view video views and customer reviews that bought our products;

- familiarize yourself with the technical characteristics, the principle of operation;

- compare different options and prices.

Quality assurance and consultation.

By communicating with our managers, you will be able to:

- get detailed information about laboratory equipment;

- choose the best equipment model according to your needs cost.

Service and warranty service.

We provide:

- a full range of service services in accordance with technical regulations;

- warranty and post-warranty service.

Read more about the service on the page service maintenance.