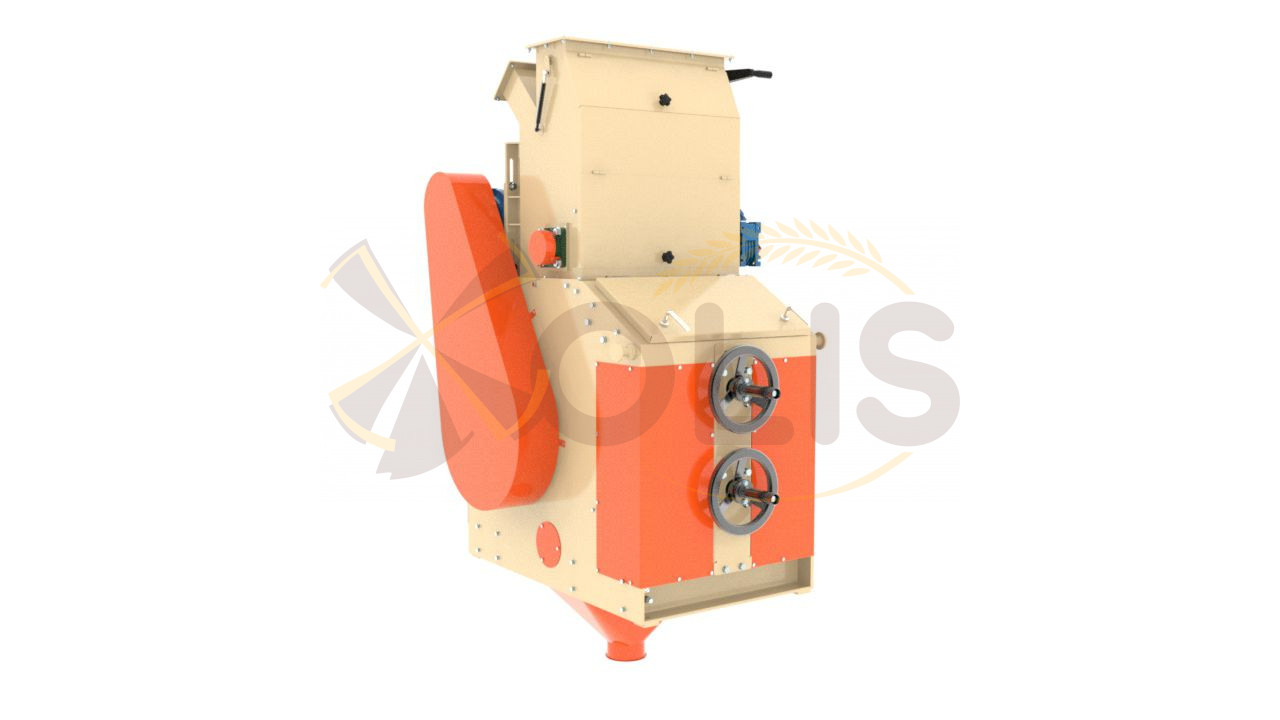

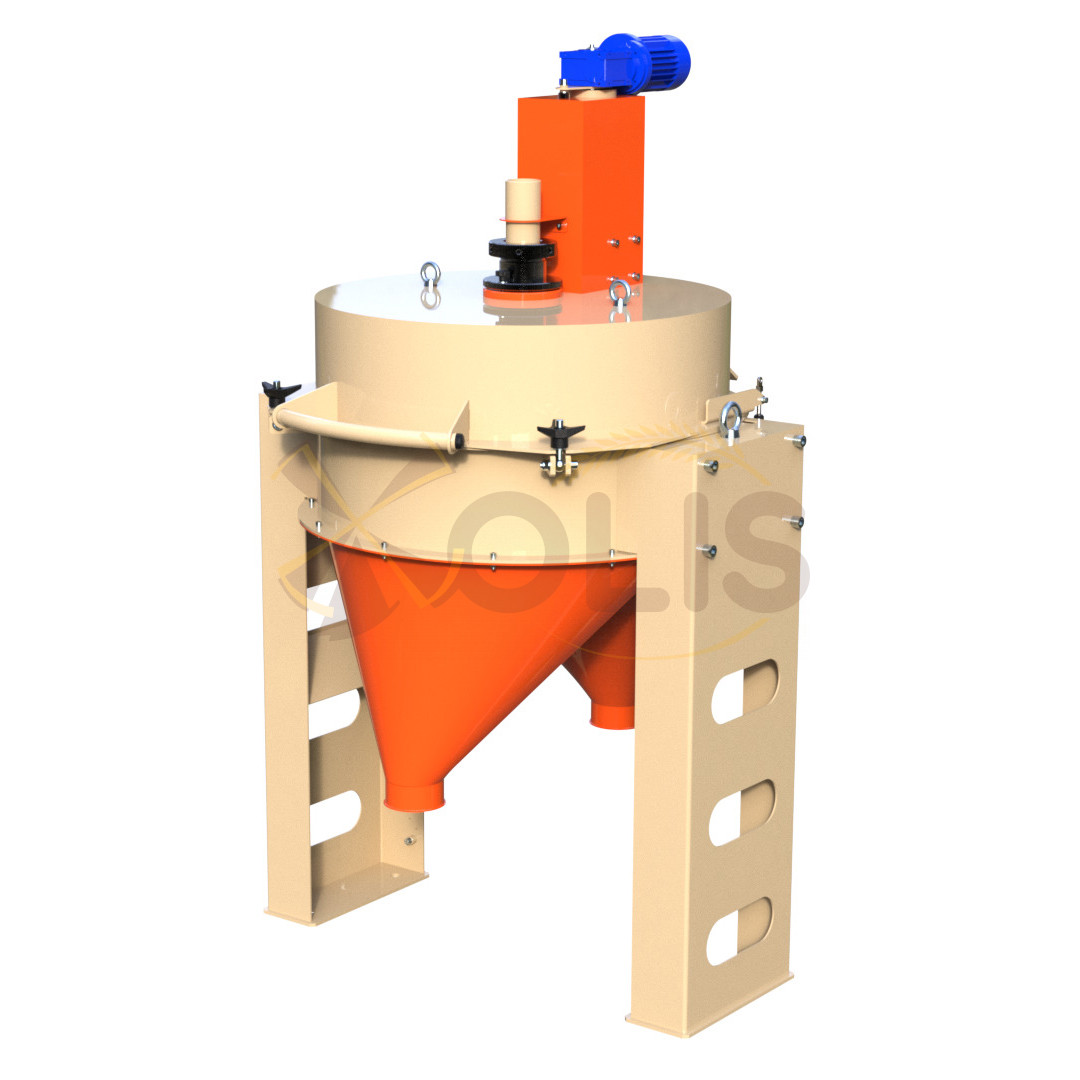

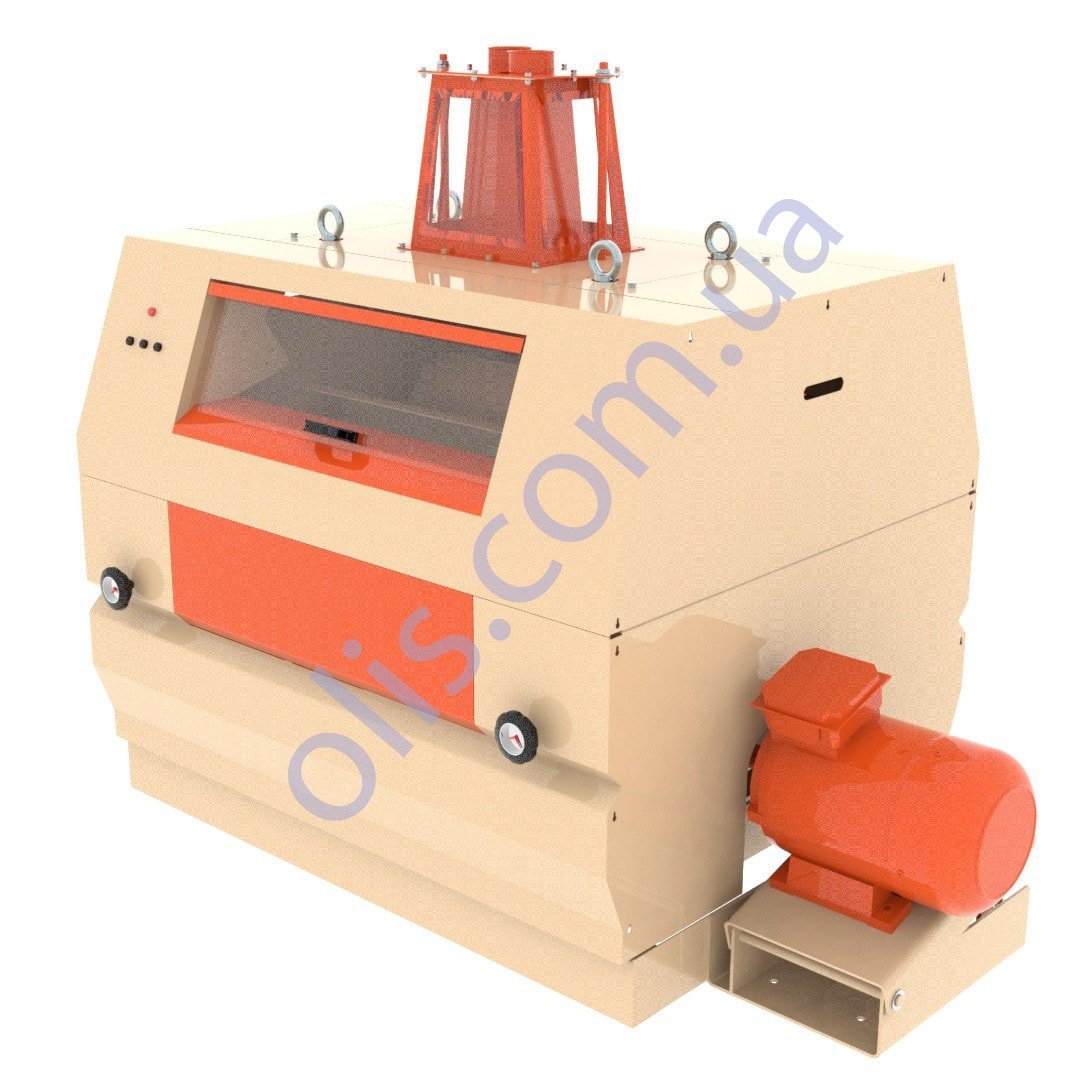

Buckwheat / millet dehuller VDM/ VDSO

Buckwheat / millet dehuller VDM and VDSO are designed for hulling buckwheat and millet at groats mills.

The initial grain with the help of the feeder enters the working area of the machine, i.e. into the working gap between the rotating abrasive roll and the stationary abrasive deck. The interaction of grain with the abrasive surfaces of these working bodies leads to grain hulling, after which the product is removed by gravity from the machine through the outlet pipe.

The initial grain with the help of the feeder enters the working area of the machine, i.e. into the working gap between the rotating abrasive roll and the stationary abrasive deck. The interaction of grain with the abrasive surfaces of these working bodies leads to grain hulling, after which the product is removed by gravity from the machine through the outlet pipe.

Product Description

Specifications

Аdvantages

Video/Photo

Additional Information

Описание

Описание

Олис

Олис

Purpose and scope of application:

Buckwheat / millet dehuller VDM and VDSO are designed for hulling buckwheat and millet at groats mills.

Description:

The initial grain with the help of the feeder enters the working area of the machine, i.e. into the working gap between the rotating abrasive roll and the stationary abrasive deck. The interaction of grain with the abrasive surfaces of these working bodies leads to grain hulling, after which the product is removed by gravity from the machine through the outlet pipe.

Specifications

Выберите модель

| Model | VDM-200 | VDSO-400 | VDSO-600 |

| Productivity up to, kg/h processed crop – buckwheat |

1,0 | 2,2 | 3,6 |

| Productivity up to, kg/h processed crop – millet |

0,7 | 1,3 | 2,0 |

| Pre-installed electric power capacity, kW | 2,2 | 5,5 | 7,5 |

| Roll length, mm | 200 | 400 | 600 |

| Roll diameter, mm | 400 | 600 | 600 |

| Roll rotation frequency, rpm | 400 | 400 | 400 |

| Air consumption for aspiration, m3/h | 250 | 500 | 750 |

| Aerodynamic resistance, Pa | 150 | 150 | 150 |

| Weight, kg | 290 | 790 | 1050 |

| Overall dimensions, mm length width height |

926 431 1032 |

1191 728 1487 |

1240 982 1637 |

Аdvantages

- A high degree of grain hulling on any fraction, which is ensured by the improved design of the machine feeder and the working gap adjustment system;

- Increased reliability of the machine and efficient aspiration system;

- Ease of installation of the machine and its maintenance in production conditions;

- Possibility of operation with ASO of the highest level;

- A separate drive on the feeder and roll – this expands the technological capabilities of the head-rolling machine.

Photos

Выберите модель

| Model | VDM-200 | VDSO-400 | VDSO-600 |

| Productivity up to, kg/h processed crop – buckwheat |

1,0 | 2,2 | 3,6 |

| Productivity up to, kg/h processed crop – millet |

0,7 | 1,3 | 2,0 |

| Pre-installed electric power capacity, kW | 2,2 | 5,5 | 7,5 |

| Roll length, mm | 200 | 400 | 600 |

| Roll diameter, mm | 400 | 600 | 600 |

| Roll rotation frequency, rpm | 400 | 400 | 400 |

| Air consumption for aspiration, m3/h | 250 | 500 | 750 |

| Aerodynamic resistance, Pa | 150 | 150 | 150 |

| Weight, kg | 290 | 790 | 1050 |

| Overall dimensions, mm length width height |

926 431 1032 |

1191 728 1487 |

1240 982 1637 |

- A high degree of grain hulling on any fraction, which is ensured by the improved design of the machine feeder and the working gap adjustment system;

- Increased reliability of the machine and efficient aspiration system;

- Ease of installation of the machine and its maintenance in production conditions;

- Possibility of operation with ASO of the highest level;

- A separate drive on the feeder and roll – this expands the technological capabilities of the head-rolling machine.

X