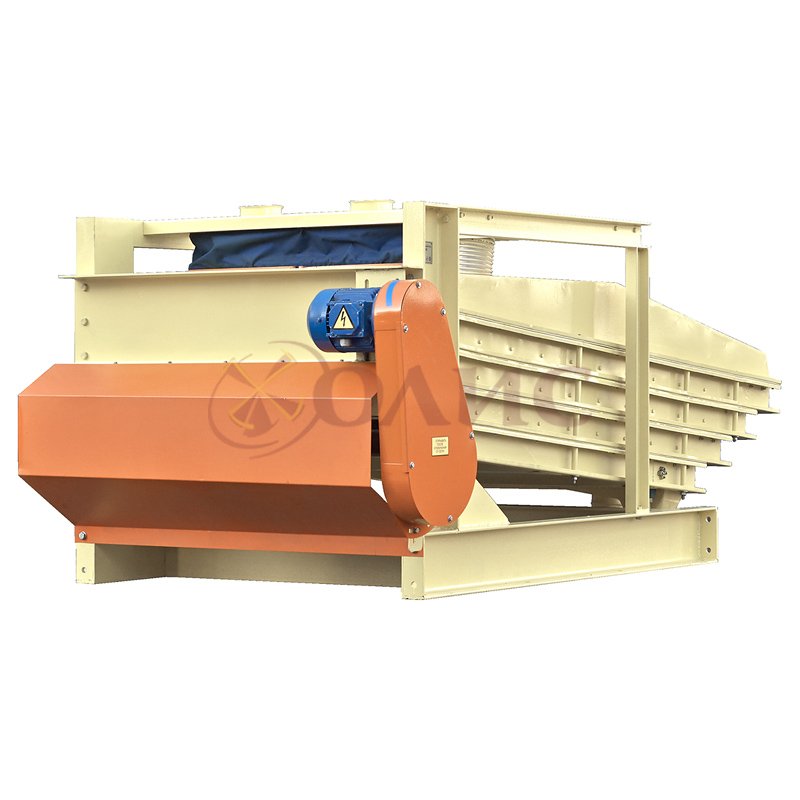

Flake Screen PKHO

Flake screen PKHO is designed for sifting oat flakes after flattening and drying, separating lumps and waste. It is used in groats shops, at oat processing plants.

Product Description

Specifications

Аdvantages

Video/Photo

Additional Information

Описание

Описание

Олис

Олис

Flake screen PKHO is designed for sifting oat flakes after flattening and drying, separating lumps and waste. It is used in groats shops, at oat processing plants.

By means of gravity transport, the product enters the upper sieves, where it goes through three stages: at the first stage, lumps are separated by sieves, at the second stage, the flakes are divided into large and small ones, and at the third stage, middling is separated.

Specifications

Выберите модель

| Model | PKHO |

| Productivity up to, t/h | up to 2-х |

| Motor power supply voltage, V | 380±20 |

| Power supply frequency, Hz | 50 |

| Pre-installed electric power capacity, kW | 1.1 |

| Air consumption for aspiration, m3/h | 300 |

| Aerodynamic resistance, Pa | 300 |

| Weight, kg | 586 |

| Overall dimensions, not more, mm length width height |

2690 1360 1145 |

Аdvantages

- The body of the flakes sieving machine is made of aluminum and stainless steel, which meets modern sanitary and epidemiological requirements.

- Convenience and ease of replacement of sieves, which ensures minimal time spent when switching to other numbers of sieves.

- Efficient sieve cleaning, allowing the entire screening surface to be used.

- Components of well-known European manufacturers are used.

Photos

Выберите модель

| Model | PKHO |

| Productivity up to, t/h | up to 2-х |

| Motor power supply voltage, V | 380±20 |

| Power supply frequency, Hz | 50 |

| Pre-installed electric power capacity, kW | 1.1 |

| Air consumption for aspiration, m3/h | 300 |

| Aerodynamic resistance, Pa | 300 |

| Weight, kg | 586 |

| Overall dimensions, not more, mm length width height |

2690 1360 1145 |

- The body of the flakes sieving machine is made of aluminum and stainless steel, which meets modern sanitary and epidemiological requirements.

- Convenience and ease of replacement of sieves, which ensures minimal time spent when switching to other numbers of sieves.

- Efficient sieve cleaning, allowing the entire screening surface to be used.

- Components of well-known European manufacturers are used.

X