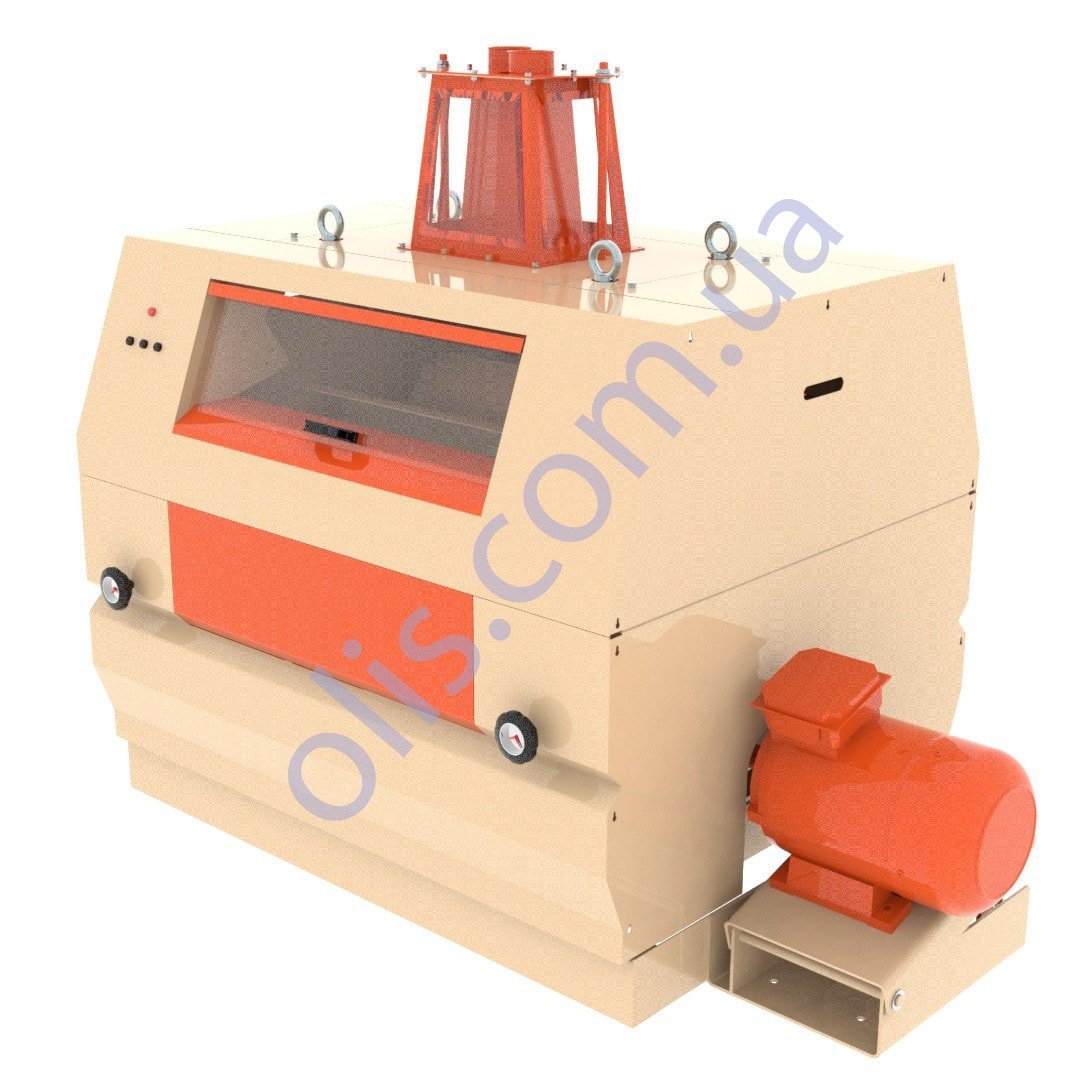

Sieving machine BM

Purpose and scope of application:

Sieving machine BM, manufactured by OLIS Ltd, is designed for sorting hulling and grinding products, as well as for monitoring waste and finished products in the grinding departments of flour mills and groats mills.

Description:

The machine consists of the body, the drive and the rotor with two sieve drums. The product entering the machine through the inlet pipe is fed by the auger into the sieve drum, where it is separated into two fractions. The bypass product enters the second sieve drum, where separation also takes place. The obtained fractions are separately removed from the machine through the outlet pipes. Sieves are cleaned using inertial cleaners and brushes.

Specifications

| Model | BM-0,8 | BM-1,2 | BM-2,0 |

| Productivity up to, kg/h of sorting of waste control |

700-800

300-500 |

1000-1200

400-700 |

1300-1800

500-900 |

| Pre-installed electric power capacity, kW | 0,55 | 0,70 | 0,75 |

| Weight, kg | 200 | 250 | 450 |

| Overall dimensions, mm length width height |

1520 840 1200 |

2000840

1270 |

2922

938 1817 |

Аdvantages

- Separation of the product into four fractions;

- No contaminations;

- Convenience and ease of replacement of sieves;

- Use of components from leading European manufacturers;

- Efficient sieve cleaning.

Photos

| Model | BM-0,8 | BM-1,2 | BM-2,0 |

| Productivity up to, kg/h of sorting of waste control |

700-800

300-500 |

1000-1200

400-700 |

1300-1800

500-900 |

| Pre-installed electric power capacity, kW | 0,55 | 0,70 | 0,75 |

| Weight, kg | 200 | 250 | 450 |

| Overall dimensions, mm length width height |

1520 840 1200 |

2000840

1270 |

2922

938 1817 |

- Separation of the product into four fractions;

- No contaminations;

- Convenience and ease of replacement of sieves;

- Use of components from leading European manufacturers;

- Efficient sieve cleaning.