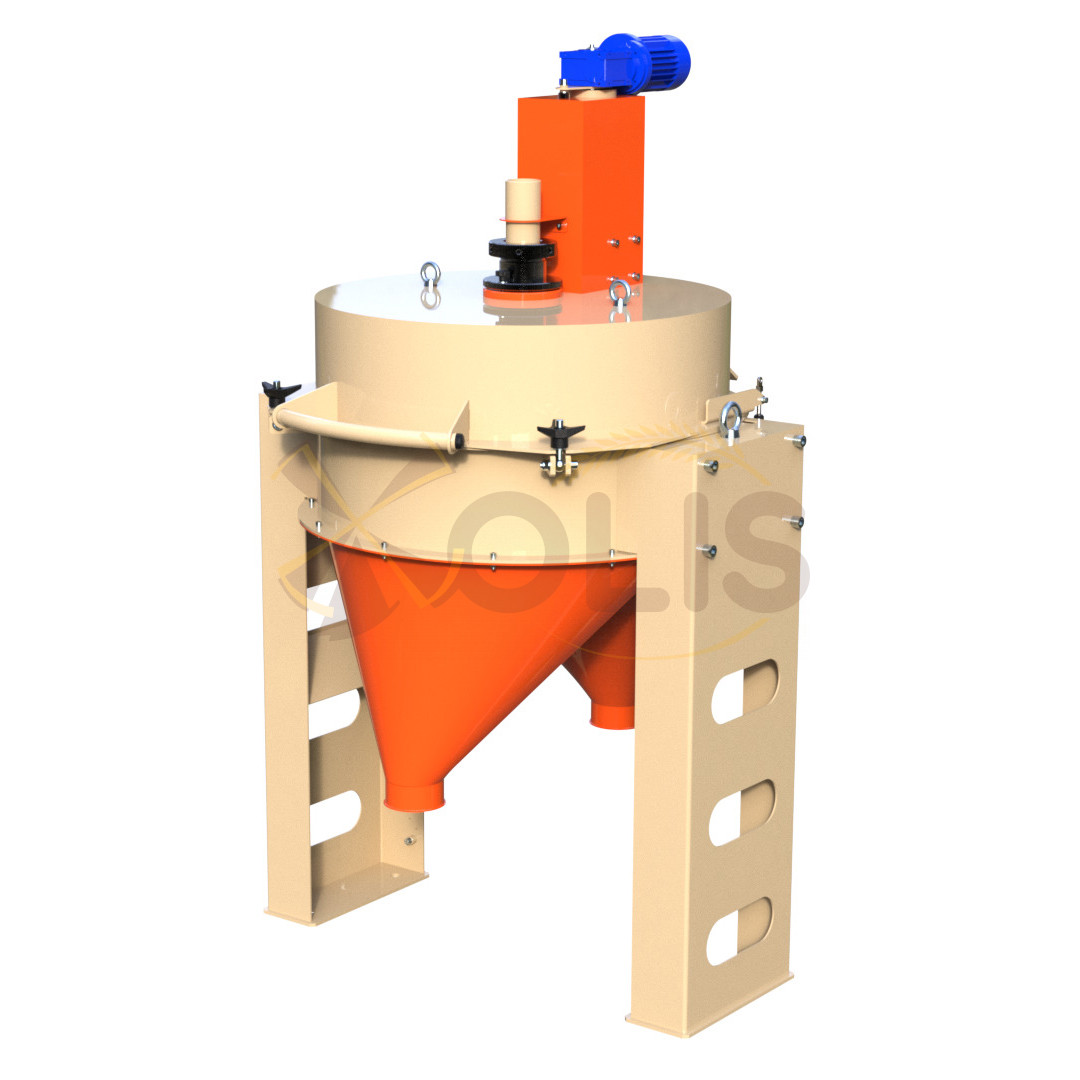

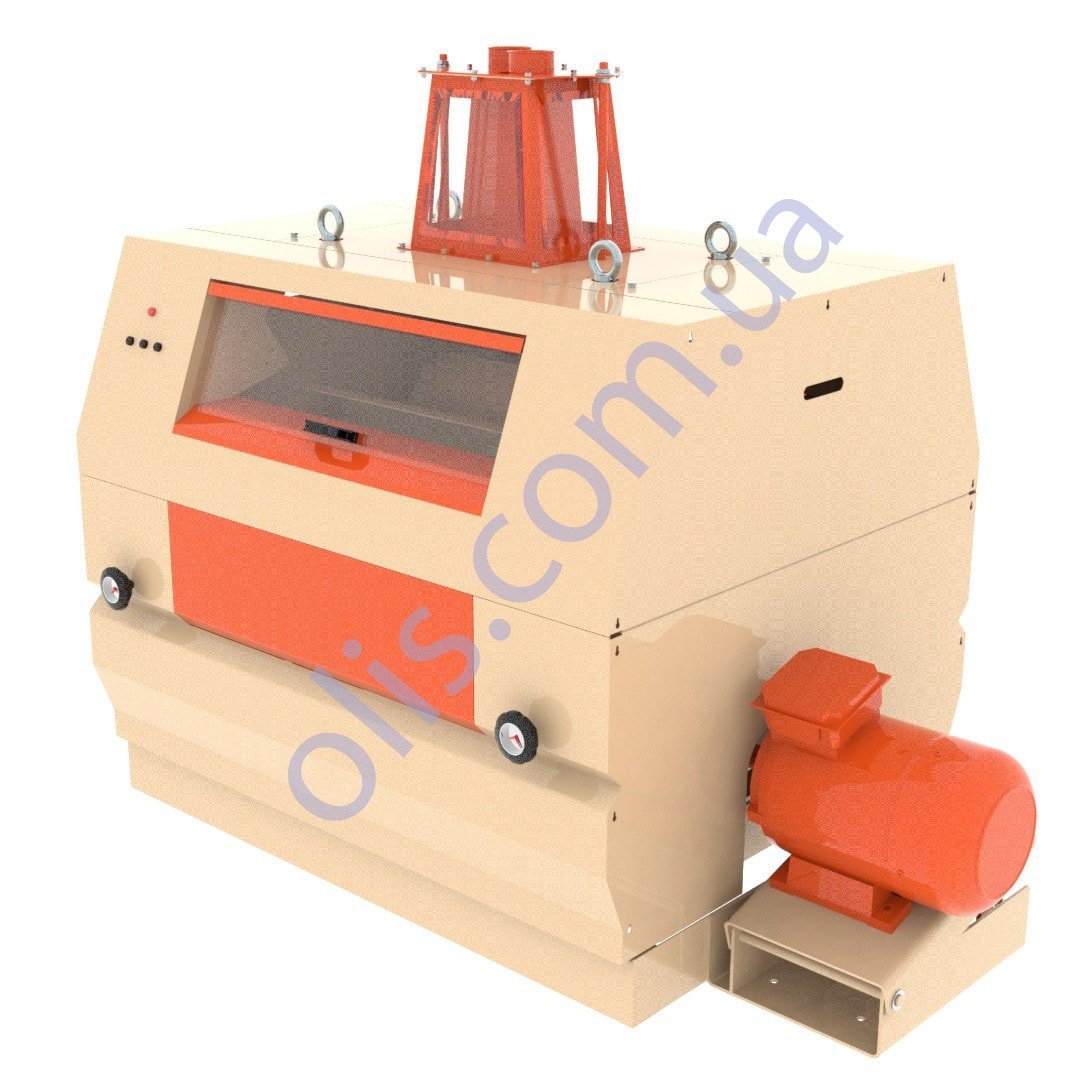

Abrasive dehuller KASKAD

Abrasive dehuller KASKAD is designed for hulling and grinding grain of wheat, barley, peas, corn and millet.

Grain hulling and grinding in the machine is carried out by abrasive discs with intensive removal of husks and flour from the working chamber into the aspiration system. The abrasive dehuller is completed with an aspiration column. To change productivity and degree of processing, tuning adjustments are provided. The machines can be additionally equipped with a feeder and operate in ASO of a groats mill.

Grain hulling and grinding in the machine is carried out by abrasive discs with intensive removal of husks and flour from the working chamber into the aspiration system. The abrasive dehuller is completed with an aspiration column. To change productivity and degree of processing, tuning adjustments are provided. The machines can be additionally equipped with a feeder and operate in ASO of a groats mill.

Product Description

Specifications

Аdvantages

Video/Photo

Additional Information

Описание

Описание

Олис

Олис

Purpose and scope of application:

Abrasive dehuller KASKAD is designed for hulling and grinding grain of wheat, barley, peas, corn and millet.

Description:

Grain hulling and grinding in the machine is carried out by abrasive discs with intensive removal of husks and flour from the working chamber into the aspiration system. The abrasive dehuller is completed with an aspiration column. To change productivity and degree of processing, tuning adjustments are provided. The machines can be additionally equipped with a feeder and operate in ASO of a groats mill.

Specifications

Выберите модель

| Model | KASKAD-0,4 | KASKAD-0,6 | KASKAD-1,6 | KASKAD-3,0-P |

| Productivity, kg/h barley in pearl barley barley in barley grits wheat, corn peas, millet |

250-350 450-500 400-550 450-600 |

350-500 600-1000 650-1050 700-1100 |

600-700 1200-1400 1300-1500 1400-1600 |

700-800 1600-1800 1800-2000 1900-2100 |

| Pre-installed electric power capacity, kW | 7,6 | 11,0 | 22,0 | 37,0 |

| Air consumption, m3/h | 500 | 650 | 800 | 1200 |

| Weight, kg | 270 | 320 | 480 | 855 |

| Overall dimensions, mm length width height |

880 590 1070 |

880 590 1115 |

1020 720 1270 |

1850 740 1280 |

Аdvantages

- Ensuring any required quality of processing in one pass;

- High uniformity of processing;

- Increase whole groats yield by 7-10%;

- Reducing the energy intensity of processing by 2-3 times;

- Convenience and speed of replacement of operating bodies.

Photo

Выберите модель

| Model | KASKAD-0,4 | KASKAD-0,6 | KASKAD-1,6 | KASKAD-3,0-P |

| Productivity, kg/h barley in pearl barley barley in barley grits wheat, corn peas, millet |

250-350 450-500 400-550 450-600 |

350-500 600-1000 650-1050 700-1100 |

600-700 1200-1400 1300-1500 1400-1600 |

700-800 1600-1800 1800-2000 1900-2100 |

| Pre-installed electric power capacity, kW | 7,6 | 11,0 | 22,0 | 37,0 |

| Air consumption, m3/h | 500 | 650 | 800 | 1200 |

| Weight, kg | 270 | 320 | 480 | 855 |

| Overall dimensions, mm length width height |

880 590 1070 |

880 590 1115 |

1020 720 1270 |

1850 740 1280 |

- Ensuring any required quality of processing in one pass;

- High uniformity of processing;

- Increase whole groats yield by 7-10%;

- Reducing the energy intensity of processing by 2-3 times;

- Convenience and speed of replacement of operating bodies.

X