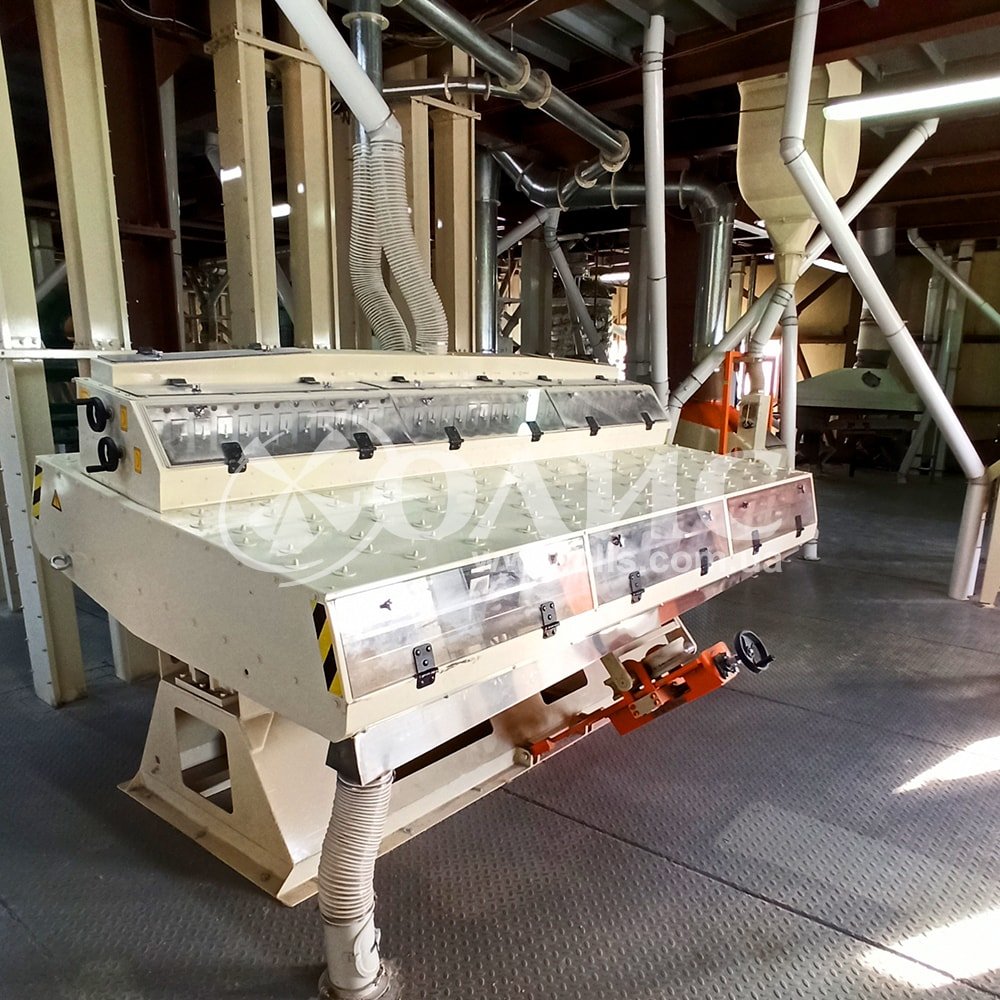

Table separator VECTOR

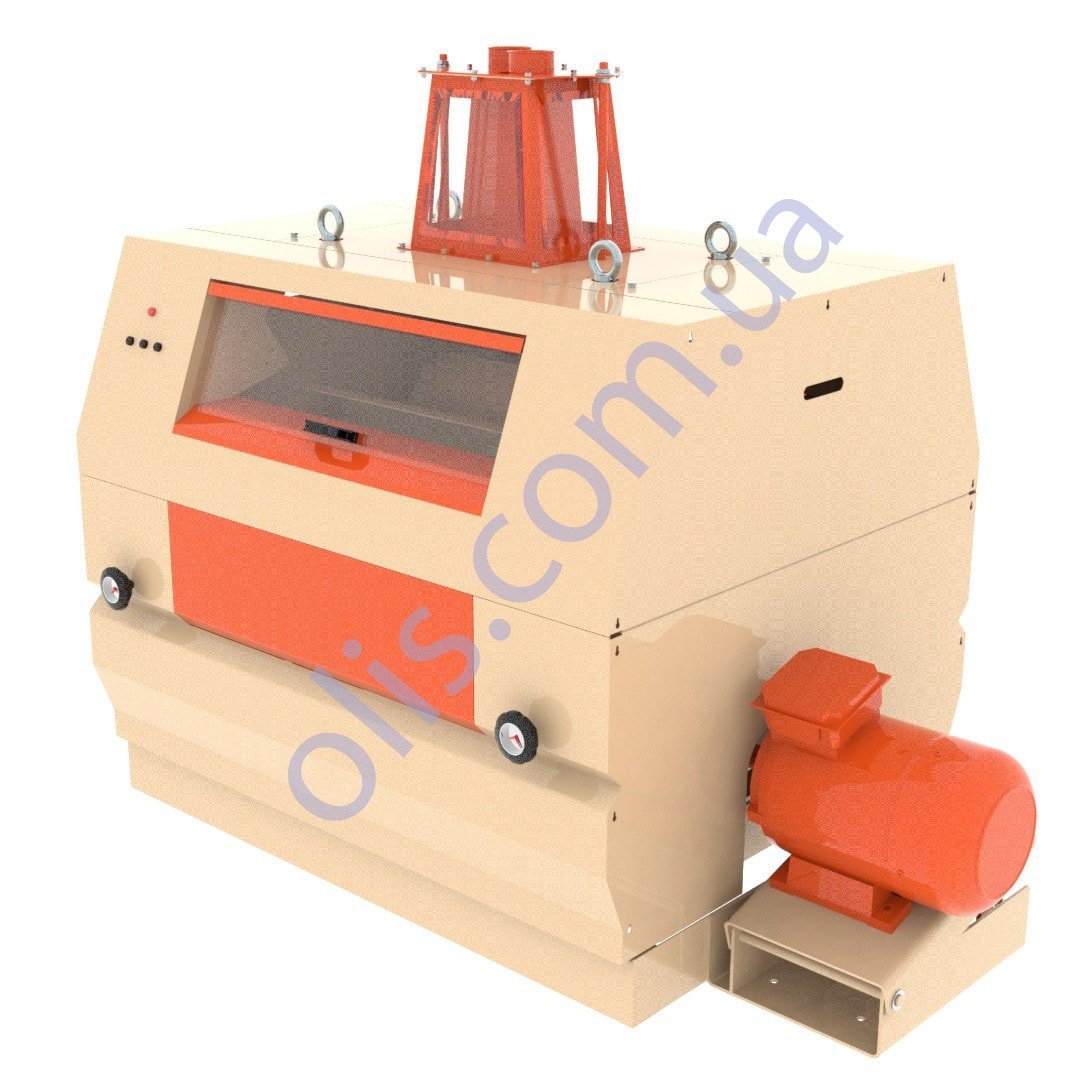

Table separator VECTOR, manufactured by “OLIS” Ltd, are designed to separate the collapsed grain from the mixture by the difference in physical and mechanical properties, as well as for control operations at groats mills. The machines are widely used in the technological processes of groats mills, and especially in the processing of buckwheat, rice and oats.

Product Description

Specifications

Аdvantages

Video/Photo

Additional Information

Описание

Описание

Олис

Олис

Table separator VECTOR, manufactured by “OLIS” Ltd, are designed to separate the collapsed grain from the mixture by the difference in physical and mechanical properties, as well as for control operations at groats mills.

The machines are widely used in the technological processes of groats mills, and especially in the processing of buckwheat, rice and oats.

Specifications

Выберите модель

| Model | VECTOR МSО-1х12 | VECTOR МSО-2х12 | VECTOR МSО-3х12 |

| Productivity, t/h buckwheat, rice oat |

1-2,5 0,8-1,5 |

2,0-3,5 1-1,5 |

3,0-4,5 1,5-2,0 |

| Number of distribution channels, pcs | 12 | 24 | 36 |

| Pre-installed electric power capacity, kW | 3,0 | 3,0 | 3,0 |

| Air consumption for aspiration, m3/h | 200 | 400 | 640 |

| Aerodynamic resistance, Pa | 200 | 250 | 300 |

| Weight, kg | 1800 | 2000 | 2500 |

| Overall dimensions, mm length width height |

2955 2110 1510 |

2955 2110 1580 |

2955 2110 1615 |

Аdvantages

- High technological efficiency;

- Stability of work on the separation of grain hulling products and on the control of finished groats;

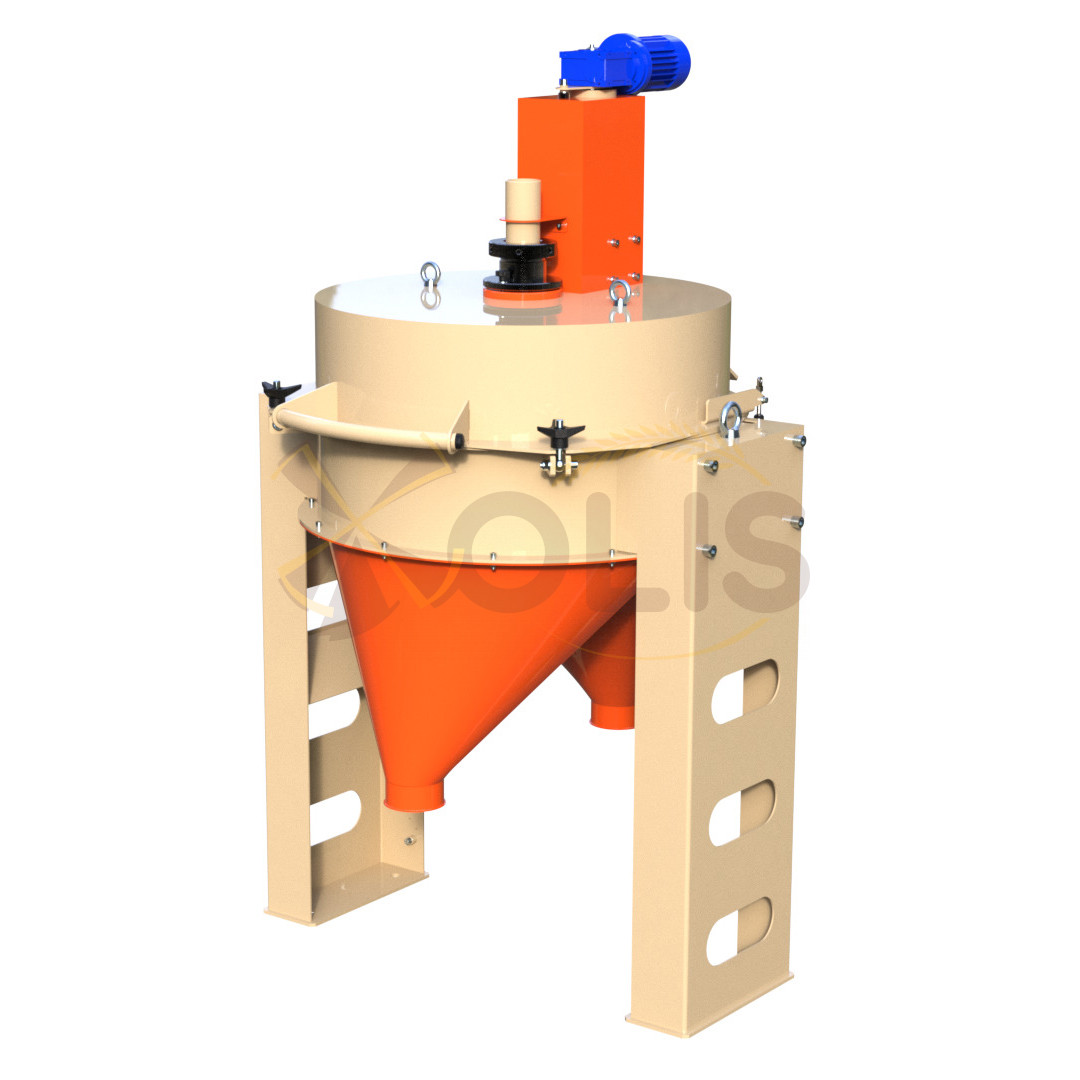

- Specially designed feeder that ensures accurate and even distribution of the product in all channels;

- Presence of an aspiration system, which can significantly reduce the accumulation of oat fluff and dust inside the machine;

- Design of the drive eliminates the occurrence of parasitic vibrations;

- Easy maintenance, convenient adjustment.

Photos

Выберите модель

| Model | VECTOR МSО-1х12 | VECTOR МSО-2х12 | VECTOR МSО-3х12 |

| Productivity, t/h buckwheat, rice oat |

1-2,5 0,8-1,5 |

2,0-3,5 1-1,5 |

3,0-4,5 1,5-2,0 |

| Number of distribution channels, pcs | 12 | 24 | 36 |

| Pre-installed electric power capacity, kW | 3,0 | 3,0 | 3,0 |

| Air consumption for aspiration, m3/h | 200 | 400 | 640 |

| Aerodynamic resistance, Pa | 200 | 250 | 300 |

| Weight, kg | 1800 | 2000 | 2500 |

| Overall dimensions, mm length width height |

2955 2110 1510 |

2955 2110 1580 |

2955 2110 1615 |

- High technological efficiency;

- Stability of work on the separation of grain hulling products and on the control of finished groats;

- Specially designed feeder that ensures accurate and even distribution of the product in all channels;

- Presence of an aspiration system, which can significantly reduce the accumulation of oat fluff and dust inside the machine;

- Design of the drive eliminates the occurrence of parasitic vibrations;

- Easy maintenance, convenient adjustment.

X