Impact Dehuller ShCO

Purpose and scope of application:

Impact dehuller ShCO is designed for hulling oat grain. It is used in groats and feed mills.

Description:

Impact dehuller ShCO works as follows. The grain to be processed from the regular bunker of the technological line by opening its valve is fed into the gravity flow of the loading operating chamber. Next, the grain enters the hammer disk, where centrifugal forces act on the grain. Due to the intense impact of the grain mass on the shell, the grain is separated from the hulls.

An important advantage of the impact dehuller ShCO SHCO-3 is that the shell has its own drive, due to which it moves in the direction opposite to the disk movement. Thus, the efficiency of the hulling process is increased, and the service life of the shell is also increased.

After the operating chamber, the grain enters the outlet funnel, where it is blown with air by aspiration. The grain processed in this way enters the standard workshop communications of pneumatic transport or gravity transport for the following operations according to the technological scheme of the workshop.

Specifications

| Model | ShCO-1,5 | ShCO-3 |

| Productivity up to, kg/h | up to 2000 | up to 4000 |

| Rotor drive power, kW | 3,0 | 4,0 |

| Shell drive power, kW | 0,09 | |

| Air consumption for aspiration, m3/hour | ||

| Rotor speed, rpm | ||

| Weight, kg | 400 | 500 |

| Overall dimensions, mm length width height |

937 917 1319 |

1175 1087 1916 |

Аdvantages

- The shell has its own drive, due to which it moves in the direction opposite to the movement of the disk. Thus, the efficiency of the hulling process is increased, and the service life of the shell is also increased;

- Convenient, easy and precise adjustment of the product supply to the hulling chamber.

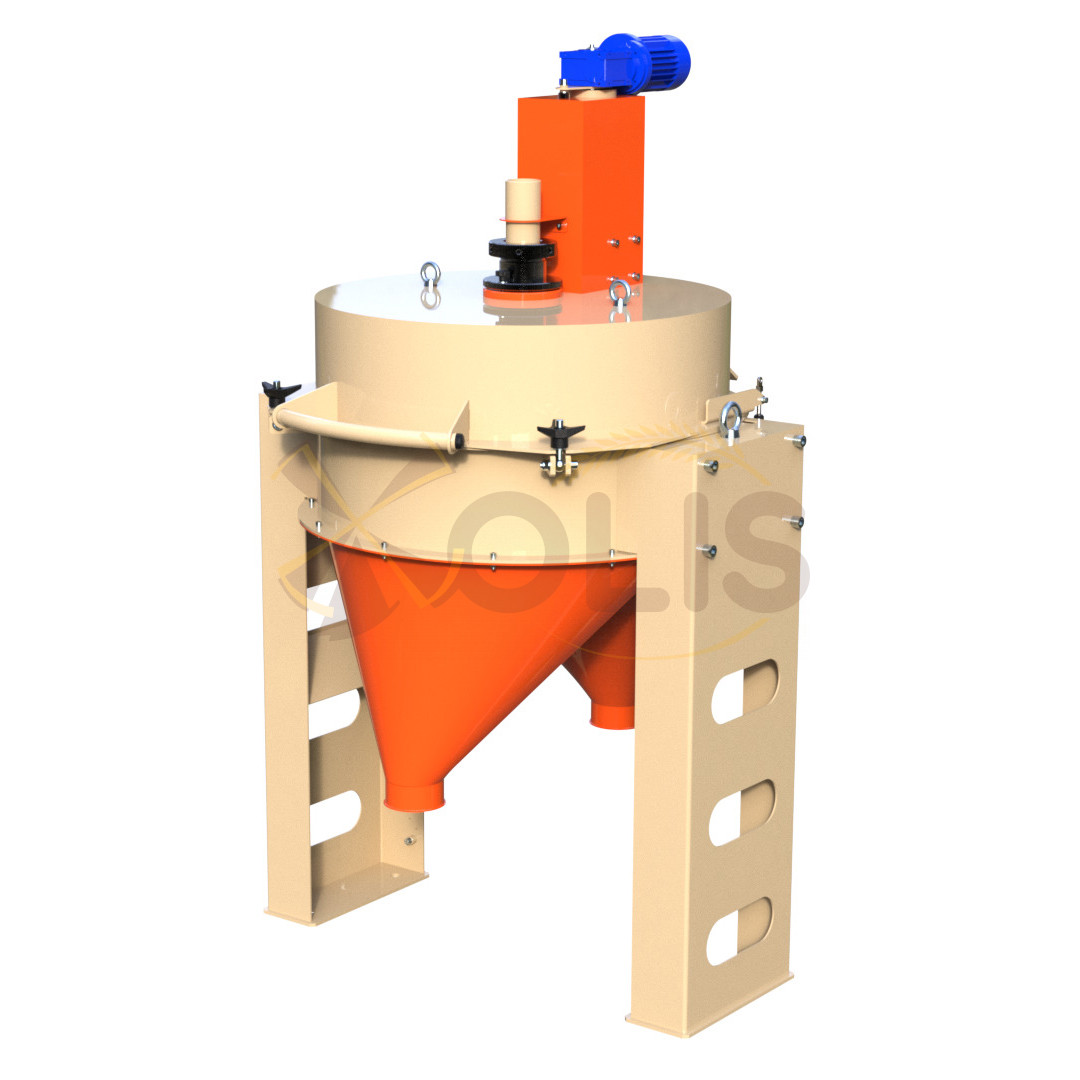

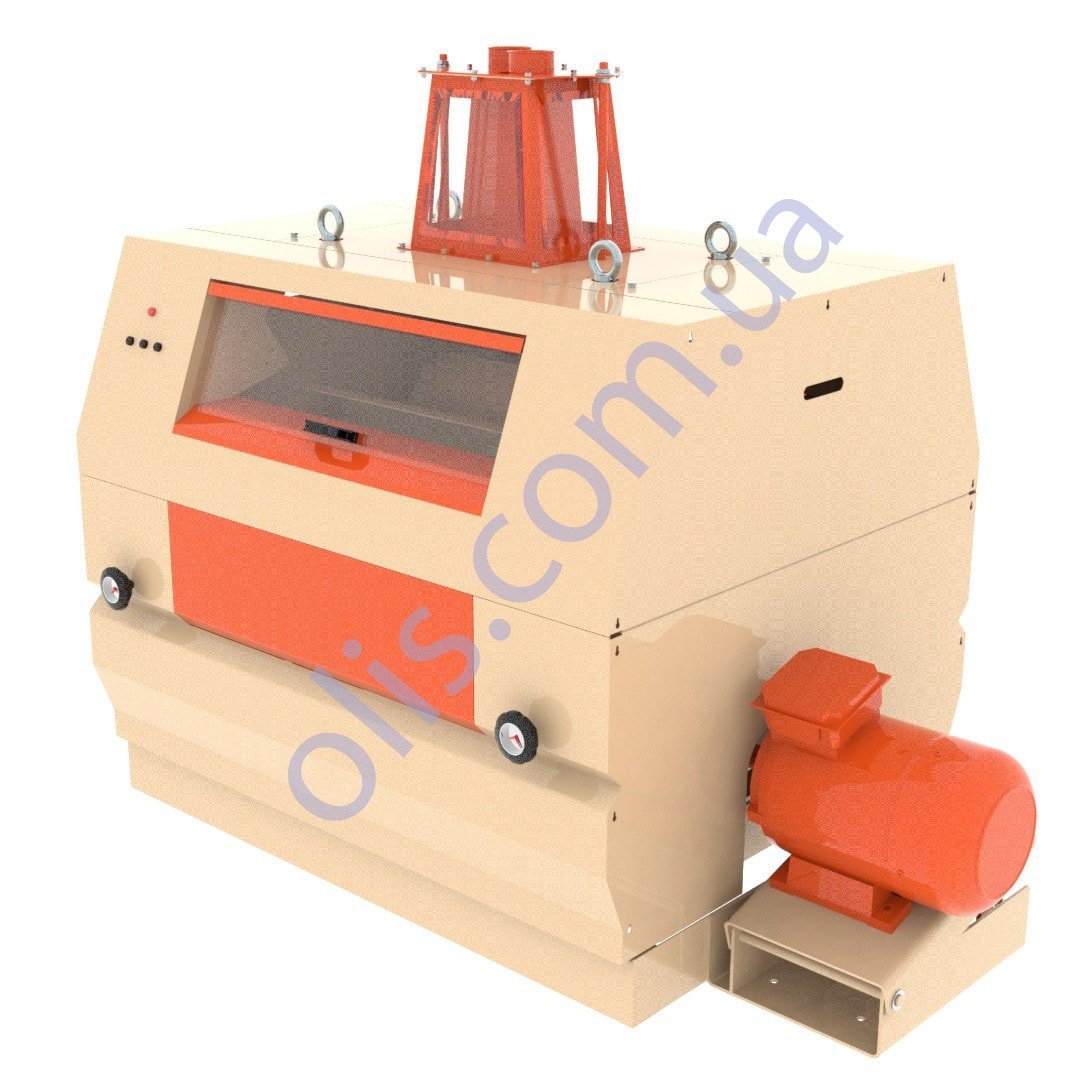

Photos

| Model | ShCO-1,5 | ShCO-3 |

| Productivity up to, kg/h | up to 2000 | up to 4000 |

| Rotor drive power, kW | 3,0 | 4,0 |

| Shell drive power, kW | 0,09 | |

| Air consumption for aspiration, m3/hour | ||

| Rotor speed, rpm | ||

| Weight, kg | 400 | 500 |

| Overall dimensions, mm length width height |

937 917 1319 |

1175 1087 1916 |

- The shell has its own drive, due to which it moves in the direction opposite to the movement of the disk. Thus, the efficiency of the hulling process is increased, and the service life of the shell is also increased;

- Convenient, easy and precise adjustment of the product supply to the hulling chamber.