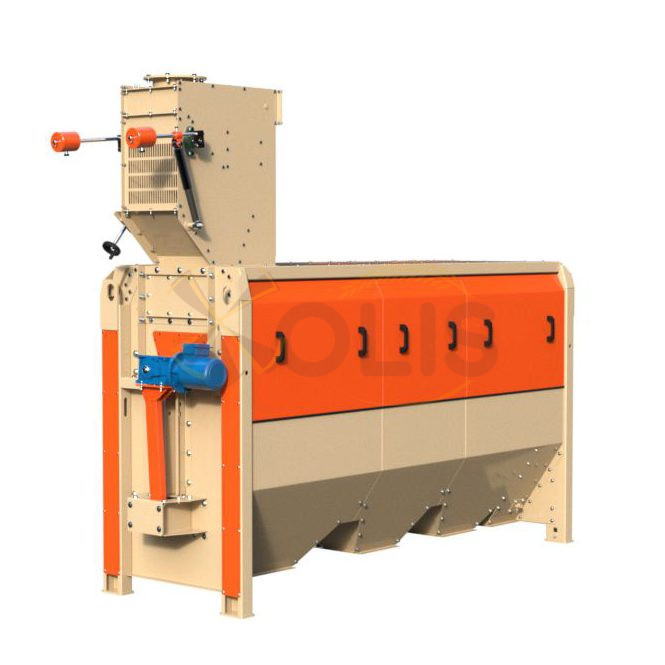

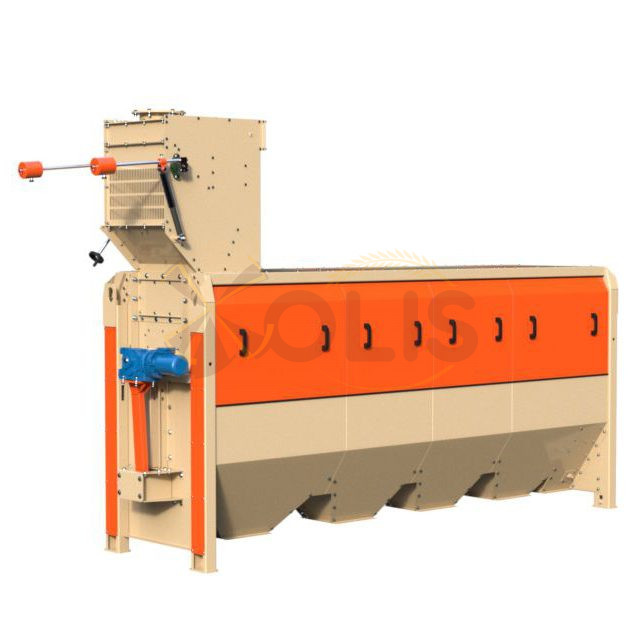

Rotary Drum Cleaner “LUCH” ZSO-200

Purpose:

Rotary drum cleaner “LUCH” ZSO-200 (drum type) is designed for cleaning grain of agricultural crops from coarse, fine and light impurities in grain elevators, mills and other grain processing facilities.

Description:

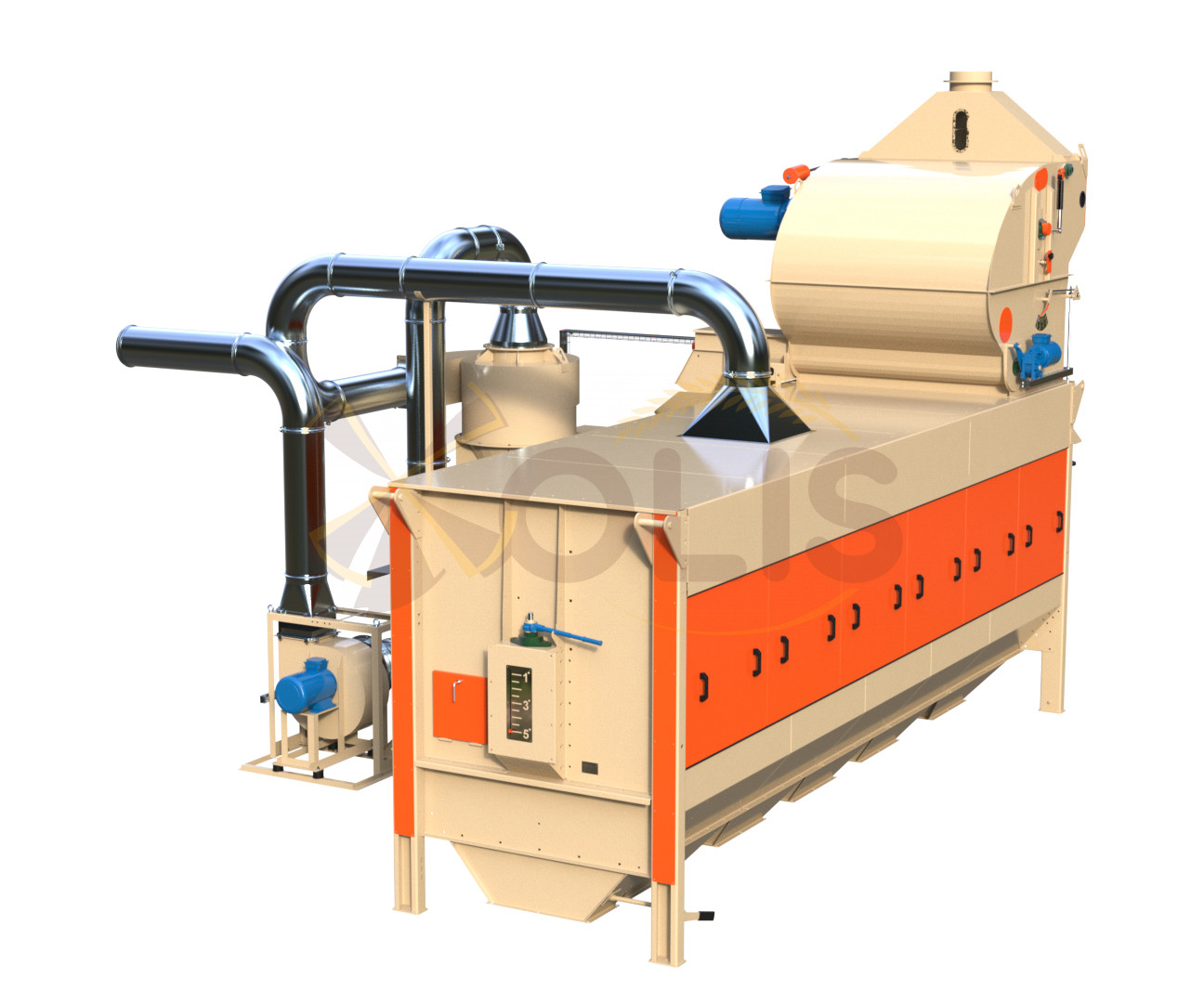

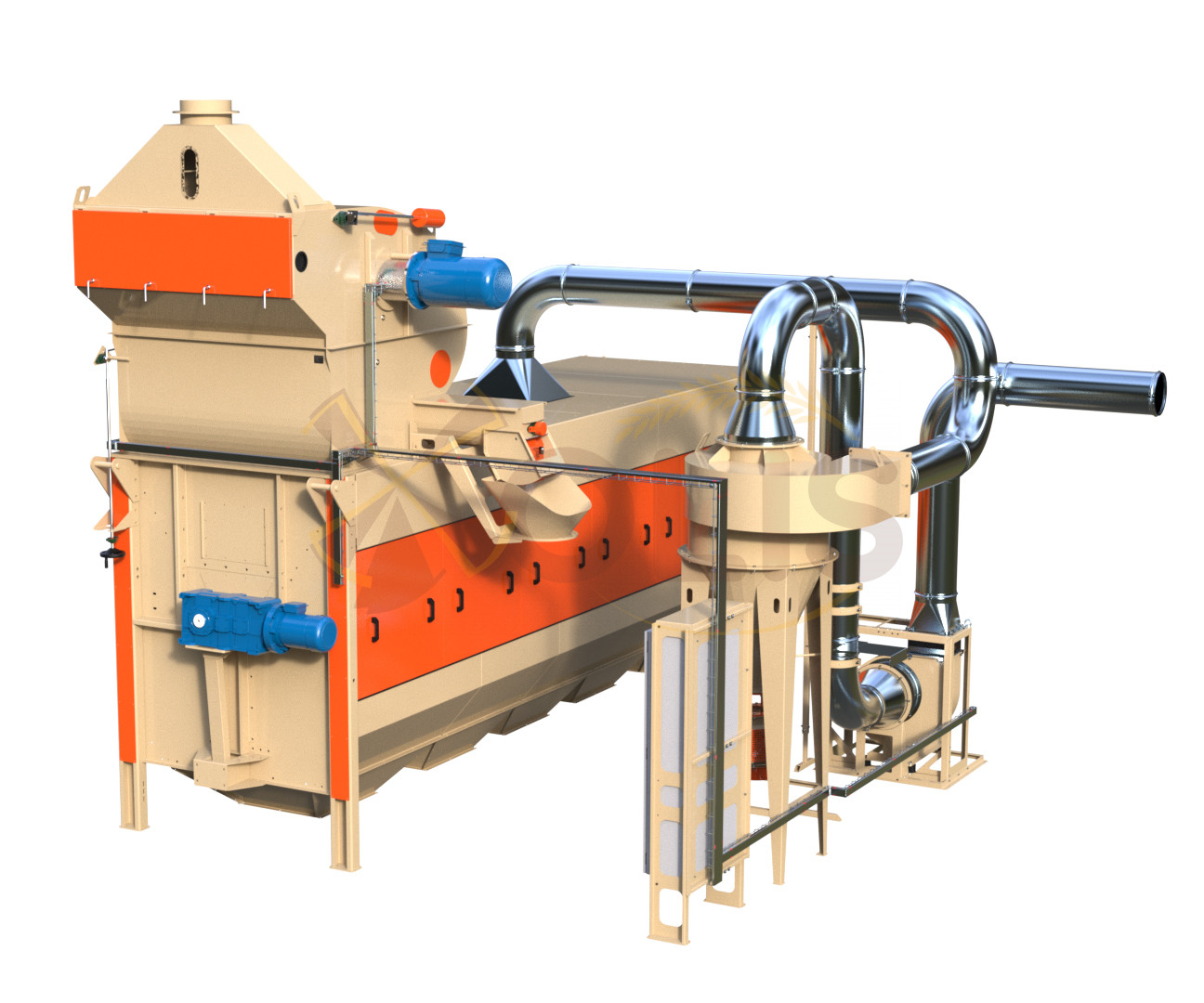

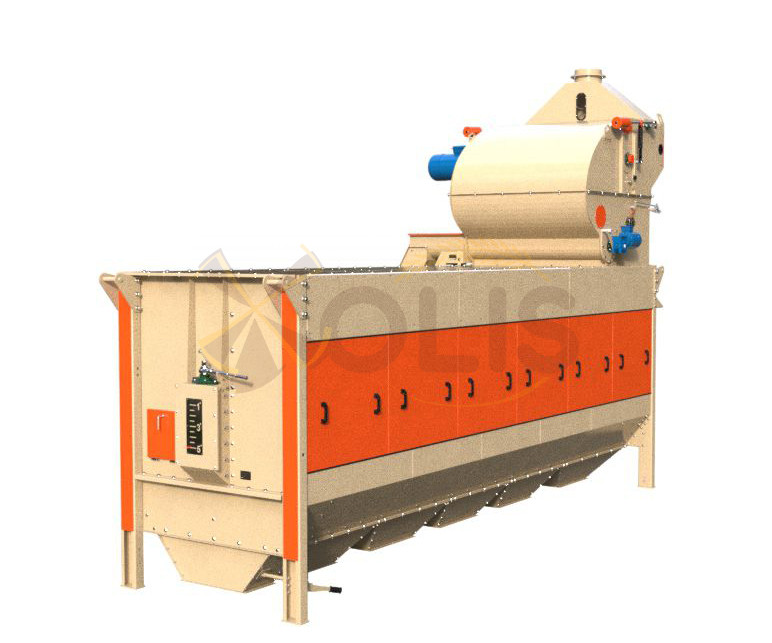

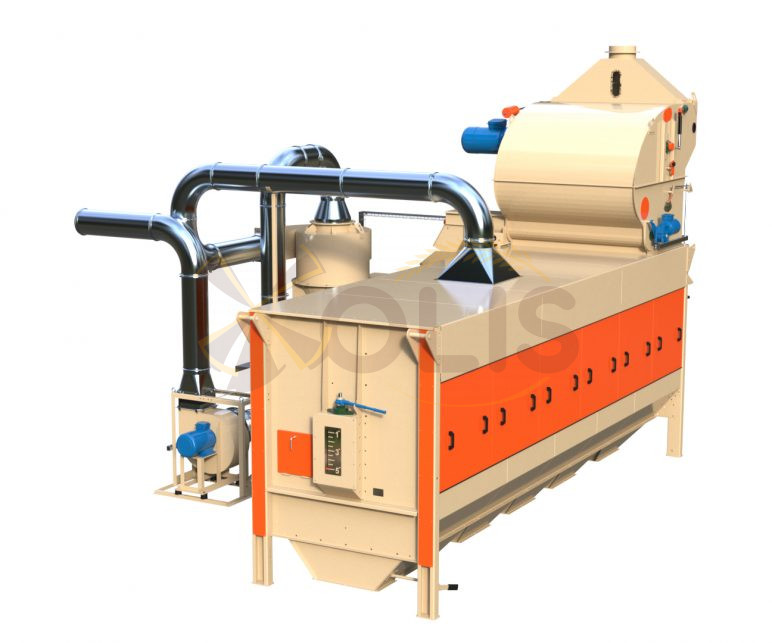

Rotary cleaning machine “LUCH” ZSO-200 consists of sieve and air separators (Fig. 1). The initial grain enters the air separator with a closed air cycle VSZ-160, where it is blown by a counterflow of air, while light impurities are separated. After that, the grain, cleaned of light impurities, enters the sieve drum, where it is cleaned of impurities which differ in size. The obtained fractions of cleaned grain, fine and coarse impurities are separately removed from the machine through the outlet nozzles. Sieves are cleaned by blocks of moving brushes and rollers.

Grain cleaning on sieves (in sieve drum separator) occurs by sieving through a rotating sieve drum according to one of selected cleaning schemes.

To operate the rotary drum cleaner LUCH ZSO-200 with the air separator VSZ-160, it is additionally necessary to install a cyclone, a fan, a control panel and air ducts.

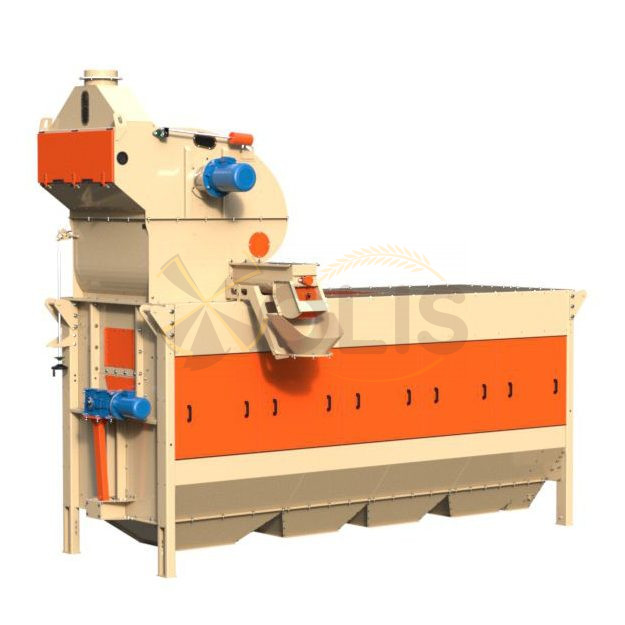

In order to simplify installation work and ensure the most efficient operation of the sieve-air separator, the company OLIS has developed an aggregated solution of LUCH ZSO-200A.

Rotary aggregate drum cleaner LUCH ZSO-200А includes rotary drum cleaner LUCH ZSO-200, air separator with a closed air cycle VSZ-160, cyclone UCO-900 with sluice gate and drive, fan, air ducts, control panel, cables, trays and ladders. (Fig. 2)

Specifications

| Model | ZSO-200 | ZSO-200А |

| Number of sections of the sieve drum | 5 | 5 |

| Diameter of the sieve drum, mm | 1260 | 1260 |

| Power of electromotor | 17,6 | 22,55 |

| Overall dimensions, mm | 7693 *3330 *5332 |

7695 *6090 *5335 |

| Weight, kg | 5199 | 5800 |

| Preliminary cleaning, t/h | 200 | 200 |

| Primary cleaning, t/h | 150 | 150 |

| Secondary cleaning (sorting, calibration), t/h | 25 | 25 |

Grain drum separator “LUCH” ZSO is a high-quality solution for cleaning all types of grain crops from the company OLIS

Schemes of grain cleaning in the grain separator “LUCH” ZSO-200

Аdvantages

- Absence of noise, vibration, as well as dynamic loads on building structures;

- Reliability, provided by simplicity and material consumption of the design;

- Bearing units, drives and electrical components are only from European manufacturers with a high reputation;

- An air separator with a closed air cycle does not require additional installation of a fan, a cyclone and air ducts for cleaning process air volumes;

- No grain damage which ensures effective separator use for seed grain cleaning;

- Common stamped sheets are used as sieves which are installed and fixed on the drum without tightening them on the frames or any other preliminary preparation;

- Effective cleaning of wet grain and grain contaminated with weed seeds;

- Possibility of changing the angle of inclination of the drum from 1° to 5°;

- Use of simple, reliable and very effective means of cleaning sieves, which is a guarantee of efficiency;

- A wide range of separators in terms of productivity allows you to choose the best option for a grain cleaning complex.

Videos

Photos

| Model | ZSO-200 | ZSO-200А |

| Number of sections of the sieve drum | 5 | 5 |

| Diameter of the sieve drum, mm | 1260 | 1260 |

| Power of electromotor | 17,6 | 22,55 |

| Overall dimensions, mm | 7693 *3330 *5332 |

7695 *6090 *5335 |

| Weight, kg | 5199 | 5800 |

| Preliminary cleaning, t/h | 200 | 200 |

| Primary cleaning, t/h | 150 | 150 |

| Secondary cleaning (sorting, calibration), t/h | 25 | 25 |

Grain drum separator “LUCH” ZSO is a high-quality solution for cleaning all types of grain crops from the company OLIS

Schemes of grain cleaning in the grain separator “LUCH” ZSO-200

- Absence of noise, vibration, as well as dynamic loads on building structures;

- Reliability, provided by simplicity and material consumption of the design;

- Bearing units, drives and electrical components are only from European manufacturers with a high reputation;

- An air separator with a closed air cycle does not require additional installation of a fan, a cyclone and air ducts for cleaning process air volumes;

- No grain damage which ensures effective separator use for seed grain cleaning;

- Common stamped sheets are used as sieves which are installed and fixed on the drum without tightening them on the frames or any other preliminary preparation;

- Effective cleaning of wet grain and grain contaminated with weed seeds;

- Possibility of changing the angle of inclination of the drum from 1° to 5°;

- Use of simple, reliable and very effective means of cleaning sieves, which is a guarantee of efficiency;

- A wide range of separators in terms of productivity allows you to choose the best option for a grain cleaning complex.