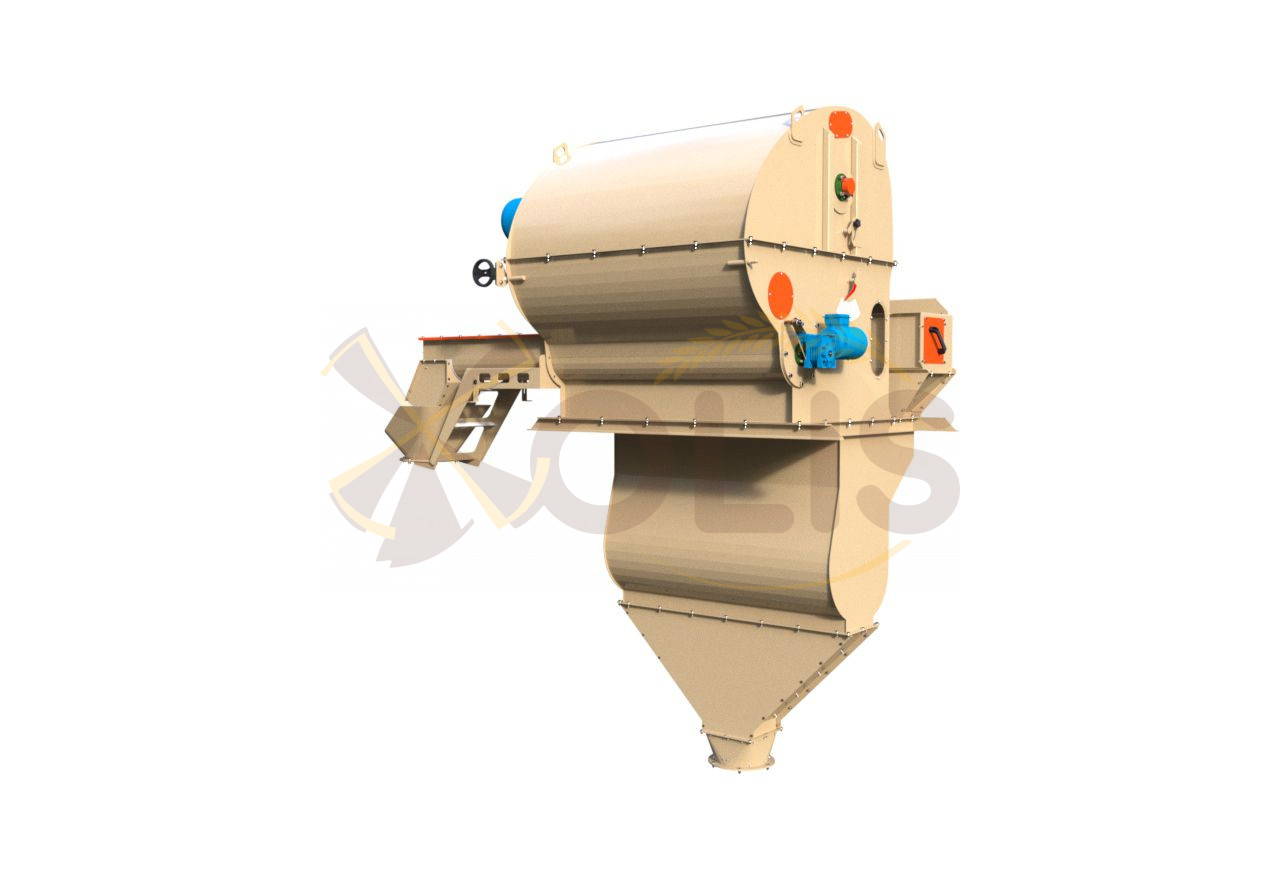

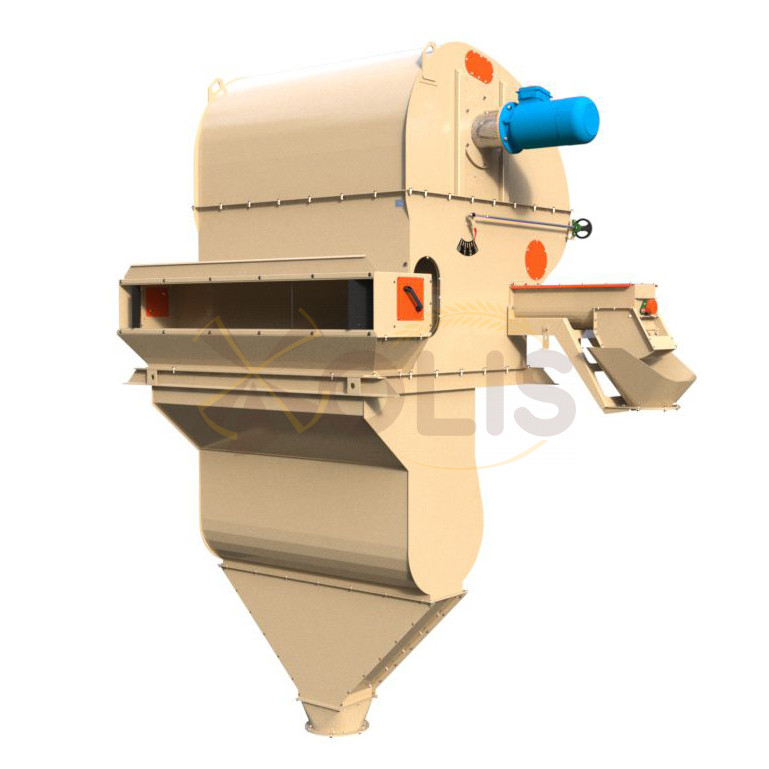

Air separator VSZM-160

Purpose:

Air separator VSZM-160 is designed for grain cleaning from impurities which differ in their aerodynamic properties. It can be used in grain storages, flour mills, feed mills and groats mills.

Air separator VSZM-160 is made with a closed air cycle, without installation of an external fan, a cyclone and air ducts, which contributes to a significant reduction of production emissions into the atmosphere in general, as well as energy savings for heating in the cold season.

Operation description:

Initial product enters the aspirating channel of the air separator where it is ventilated by the upward flow of the air created by tangential flow fan. Purified product is discharged from the machine by gravity. Light impurities are separated in the sediment chamber and removed via the screw conveyor and the air is supplied to the aspirating channel for later use.

Specifications

| Model | VSZM-160 |

| Throughput productivity*, t/h | up to 200 |

| Pre-installed electric power capacity, kW | 12,1 |

| Length of the operating channel, mm | 1600 |

| Weight, kg | 1500 |

| Overall dimensions, mm length width height |

2135 2640 3445 |

*Footnote. Per wheat grain of basic condition (garbage admixture is no more than 2%, moisture content is no more than 13%)

Аdvantages

- It has a closed air cycle, due to which there is no need for air ducts and cyclones for cleaning exhaust air;

- There are no emissions of exhaust air into the atmosphere;

- High degree of grain cleaning;

- Coarse and precise air adjustment is provided, which achieves smoothness of adjustment, which allows to achieve high-quality cleaning of all types of grain;

- Use of components from leading European manufacturers.

Photos

| Model | VSZM-160 |

| Throughput productivity*, t/h | up to 200 |

| Pre-installed electric power capacity, kW | 12,1 |

| Length of the operating channel, mm | 1600 |

| Weight, kg | 1500 |

| Overall dimensions, mm length width height |

2135 2640 3445 |

*Footnote. Per wheat grain of basic condition (garbage admixture is no more than 2%, moisture content is no more than 13%)

- It has a closed air cycle, due to which there is no need for air ducts and cyclones for cleaning exhaust air;

- There are no emissions of exhaust air into the atmosphere;

- High degree of grain cleaning;

- Coarse and precise air adjustment is provided, which achieves smoothness of adjustment, which allows to achieve high-quality cleaning of all types of grain;

- Use of components from leading European manufacturers.