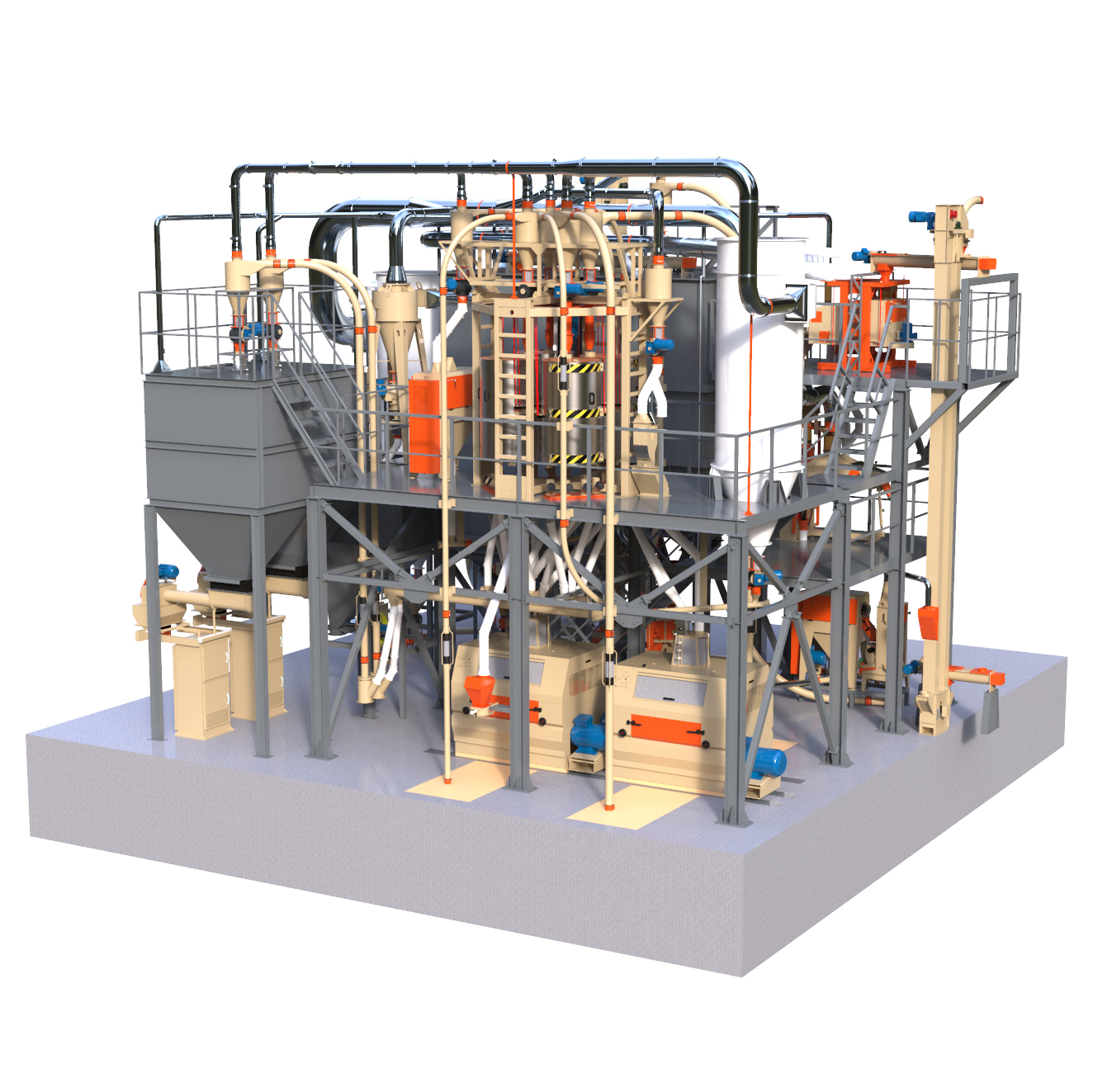

Complete Mill Plant for Grade Wheat Milling with production capacity of 500 tons / day (24 hours)

Purpose:

Complete Mill Plant with production capacity of 500 tons/day (24 hours) consists of two independent sections with production capacity 250 tons/day (24 hours) each, and is designed for processing wheat grains into graded flour to obtain high-grade, first-grade and second-grade flour, as well as semolina. The mill plant performs milling due to compact structure and solves the task of flour supply to bread-making plants, confectioneries and pasta factories on the interregional and national levels. The mill plant is capable of meeting the processers’ export needs including yields of special grades (sorts) of flour.

Description:

To mount the mill plant, a 4-storey building with an overall height of 18m and at least 760m2 of surface area for each floor is required. Recommended dimensions of the building are 20х38 m in plan view. The mill plant operates automatically. Performance control of the mill plant is supported by the operator from the central control panel.

For successful and failure-free operation, the mill plant shall be provided with:

- The line for grains acceptance from motor-vehicle transport (railway transport), as well as the preliminary cleaning;

- The elevator for distribution and storage of operating supply of grains with a line designed for forming mill-blends and their transferring for milling;

- The weighing and packing department with a possibility of packing both into bags and into small packages;

- The warehouse for bulk storage and mill-offal granulation with a delivery line to motor-vehicle transport (railway transport);

- The warehouse for bulk storage of flour with a delivery line to motor-vehicle transport (railway transport);

The mentioned above communications can be developed in the framework of implementing individual design projects due to particular technical tasks.

Specifications

Basis yield of flour will depend on the type actual milling

(from the grains of basic conditions):

Due to the reduction of flour yield, selection of semolina is possible. The reasonable rate of semolina selection is 1,5-3,0 %.

3 phase alternative currency

voltage, V

frequency, Hz

50

Estimated composition of equipment:

Аdvantages

- Highest flour yield and quality, low energy costs.

- Efficient processing of grain of low milling conditions.

- Possibility of selection of semolina, grits, flour and bran, which are part of the recipe of a number of bread varieties.

- It is best suited for re-equipment of existing mills of different periods of construction.

- Operation of the mill is carried out in automatic mode.

- Reliability of the equipment ensures uninterrupted and long-term operation of the mill.

- The mill is able to meet the export needs of flour, including the production of its special types (grades).

Photo

Basis yield of flour will depend on the type actual milling

(from the grains of basic conditions):

Due to the reduction of flour yield, selection of semolina is possible. The reasonable rate of semolina selection is 1,5-3,0 %.

3 phase alternative currency

voltage, V

frequency, Hz

50

Estimated composition of equipment:

- Highest flour yield and quality, low energy costs.

- Efficient processing of grain of low milling conditions.

- Possibility of selection of semolina, grits, flour and bran, which are part of the recipe of a number of bread varieties.

- It is best suited for re-equipment of existing mills of different periods of construction.

- Operation of the mill is carried out in automatic mode.

- Reliability of the equipment ensures uninterrupted and long-term operation of the mill.

- The mill is able to meet the export needs of flour, including the production of its special types (grades).