Confectionery sunflower seeds are intended for obtaining kernels, not oil, which determines their technological and consumer properties. The weight of 1,000 confectionary sunflower seeds exceeds 100 g, the kernel is large and does not adhere to the husk as tightly as in oil sunflower, the husk content exceeds 40%, and the fat content is within 30-35%. Most of the grown confectionery sunflower is exported to the countries of the European Union, where it is processed into a kernel and used in the preparation of salads, included in the composition of bakery and culinary products.

In Ukraine, the cultivated area under confectionery sunflower occupies about 20% of all areas occupied by sunflower crops. The profitability of growing confectionery sunflower is 25-30% higher than the profitability of growing oil sunflower, which determines the interest in its cultivation. On the domestic market, the kernel of confectionery sunflower (Fig. 1) is traditionally used in a toasted form as a snack, as well as for the production of halva and kazinaki.

Only large fractions of seeds are suitable for processing into kernels. A small fraction of the seeds is used for fodder for birds, domestic animals or for processing into oil.

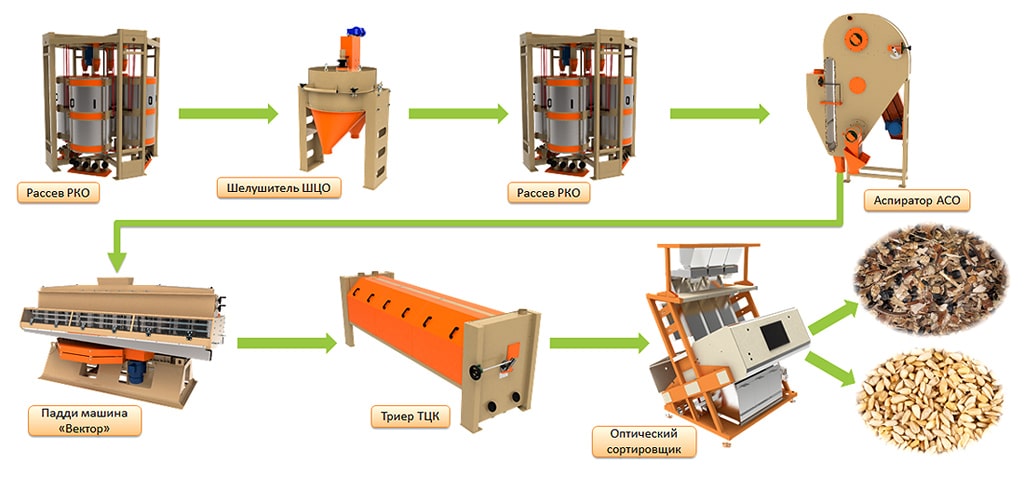

The technology of processing sunflower into a kernel (Fig. 2) involves its thorough cleaning and calibration, crushing, sorting by size, winnowing to separate the husk, separating the crushed grains and their control. The main problem of confectionery sunflower processing is the use of industrial-level technological lines equipped with various adapted equipment for these purposes. As a rule, such lines require long-term proofing, which consists in numerous modifications and additional equipment.

The list of technological equipment manufactured by OLIS allows us to create industrial lines for processing confectionery sunflower into kernels of the highest efficiency within a wide range of productivity. Self-balancing plansifter RKO-4, impact dehuller ShCO, air separator ASO, table separator VECTOR, indented cylinder TCK are the basis for efficient, industrial sunflower kernel processing and the key to your successful business.

We produce: