Complete corn processing plant with germ separation with productivity 100 t/ day

Purpose

The complete corn processing plant with productivity 100 t/day is designed to produce corn grits with germ separation. The obtained groats are characterized by low fat content, which contributes to their wide use in the production of snacks by extrusion method, in beer formulation, and for the preparation of various porridges, confectionery products. The plant is created by traditional technology, significantly improved, and complemented by a number of innovations from OLIS company

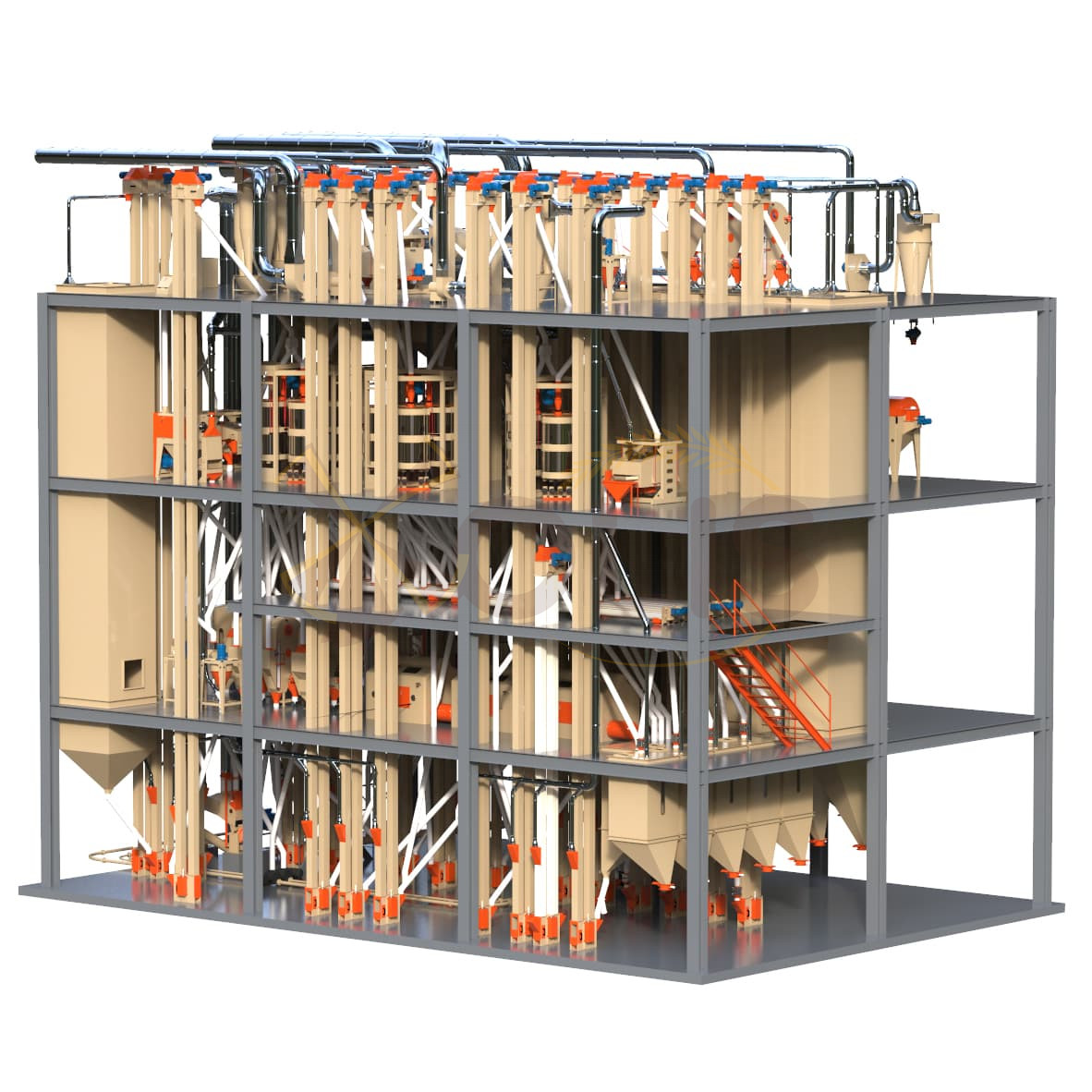

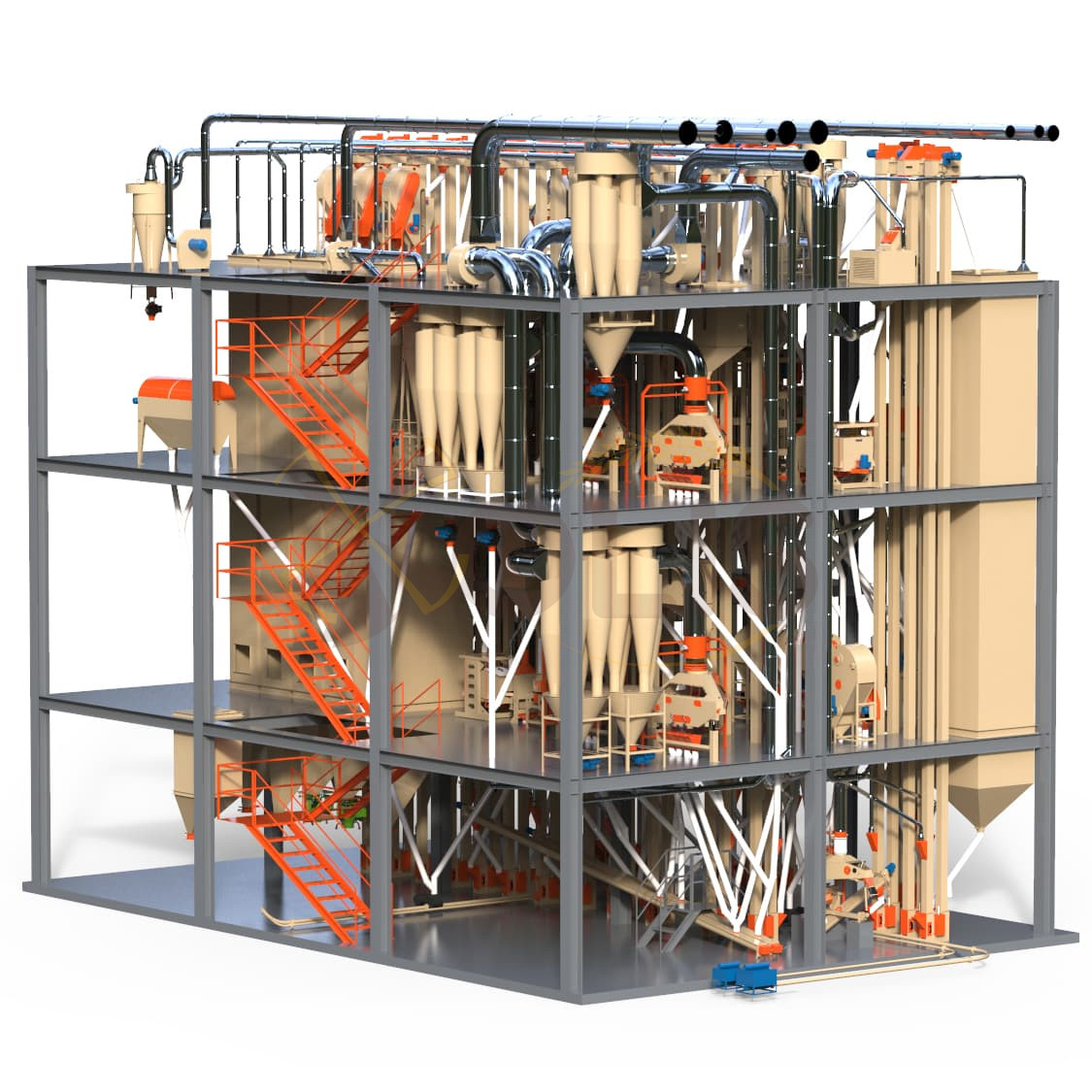

To place the plant, a 4-story building with a floor height of at least 3 m and an area of each floor not less than 200 m ² is appropriate. In the absence of an appropriate building, steel frameworks for the placement of equipment is recommended to be constructed in the form of a four-tiered frame up to 12 m in height with dimensions of 12 m x 18 m in plan and set on their own foundations. In this case, the external enclosures (walls and roof) it is advisable to arranged on reinforced concrete structures and foundations, independent of the load-bearing equipment of steel structure. The expected height of the building – 16 m. The construction part can be supplemented with rooms for the operator’s room, laboratory, warehouses, etc.

As part of fulfilment individual project to the plant can be tied such utilities as:

- The receiving line of grain from vehicles and pre-cleaning;

- Warehouse placement and storage of the operative stock of grain with the line of its supply to the processing;

- Weight-unloading section with the possibility of selecting the finished product both in bags and in small packaging;

- Warehouse bulk storage of flours and husks with a line of loading on trucks;

The plant operate in automatic mode. The operator from the central control desk provides control of the plant.

Specifications

Output of finished products from basic quality grain

(humidity – 14%, trash – 1%, grain admixture – 2%)

* – fat content 0.6-1.2%;

** – fat content 1,2-1,5%.

Voltage, 380W, 50Hz

Equipment composition of the plant

Аdvantages

- Guaranteed low-fat groats and flours at the highest possible yield.

- Minimum content of “dark” inclusions in the groats, i.e. particles of the gillard layer.

- The possibility of processing grains of low quality, providing an acceptable yield and high quality of the finished product.

- Increased yield of flour and groats by using the floury layer of the endosperm of grain.

- Using the germ of the grain to produce oil and cake.

- Possibility to produce one or two numbers of groats and flour or entirely flour without readjustment.

- Operation of the groats factory in automatic mode.

- Reliability of the equipment provides uninterrupted and long-lasting operation of the groats plant.

- Payback period of 2-3 years due to the exclusion of expensive equipment of Western manufacturers and high operating costs for wear parts.

Output of finished products from basic quality grain

(humidity – 14%, trash – 1%, grain admixture – 2%)

* – fat content 0.6-1.2%;

** – fat content 1,2-1,5%.

Voltage, 380W, 50Hz

Equipment composition of the plant

- Guaranteed low-fat groats and flours at the highest possible yield.

- Minimum content of “dark” inclusions in the groats, i.e. particles of the gillard layer.

- The possibility of processing grains of low quality, providing an acceptable yield and high quality of the finished product.

- Increased yield of flour and groats by using the floury layer of the endosperm of grain.

- Using the germ of the grain to produce oil and cake.

- Possibility to produce one or two numbers of groats and flour or entirely flour without readjustment.

- Operation of the groats factory in automatic mode.

- Reliability of the equipment provides uninterrupted and long-lasting operation of the groats plant.

- Payback period of 2-3 years due to the exclusion of expensive equipment of Western manufacturers and high operating costs for wear parts.