General Director of “OLIS, Ph.D. Vereshchynsky A.P .

“Grain storage and processing” – № 1 2009

Separation is one of the most important operations in the cultivation, storage and processing of grain. The degree of purification and classification of seed in many ways affect the crop. The degree of separation of the grain piles after harvest determines the stability of grain quality during storage. Cleaning grain to flour and cereal plants determines the quality of the finished product. Selecting the method of separation depends on the core topics differences particles of components that must be divided. However, in any case, any grain necessarily be cleaned in a sieve, air separators, consisting, respectively, from the air and sieve separators. When cleaning in the air separator air flow, blowing seed, takes light impurities. Thus, the grain is separated from the main part of the stems and ears of corn, chaff, weed seeds, a frail, eaten by pests of grain, dust, etc. Sieving grain mass separators in sieving on sieves provides separation of the geometric dimensions (thickness and width). Since the grain is cleaned of major and minor impurities, as well as calibrated by fractions size. On a design major working organs sieve separators are divided into cages with flat or cylindrical screens. In turn, the cylindrical screen can be made in the form of vertical sieve cylinders or horizontal sieve drum.

The implementation process of screening on the flat sieve in the sieve of vertical cylinders required to bring them to vibrate, which is achieved using a variety of oscillatory and vibratory drives. Vibrations generated by the supports and the suspension transferred to the frame separator, and then on building structures. Caused thereby, dynamic loads and resonance phenomena are very important, which requires a corresponding increase of foundations, columns, beams and other elements of building structures, as well as the high degree of rigidity. Thus, the cages with flat or vertical cylindrical sieves are complex drive, require high strength and rigidity of the moving parts and frames, which reduces their reliability. Generated by fluctuations in the form of noise and vibration create adverse impacts on staff. In addition, for the installation of separators to the construction material-building designs that require significant expenditures.

These deficiencies deprived separators with horizontal sieve drum. In these separators to be cleaned grain is fed into a rotating drum, moving from an input to its output under the influence of backwater and a small slope. When rolling on the sieve surface, the grain is sifted through a sieve. Part of the grain that has not passed through a sieve to the next screen comes at the end of the drum displays shedding. For an organization of workers sifting fluctuations are not required. The prerequisites for screening is provided only by rotating the drum about its axis at low speeds. Consequently, in the separators of this type dynamic loads on the working bodies, beds, and constructions are virtually absent. Such separators are considerably easier, safer, and can be installed and mounted with a much lower cost. It should be noted that in contrast to flat screens, the use of cylindrical sieve drum creates conditions for the use of simple, reliable and very effective means of cleaning screens, that is the key to the effectiveness of separation.

The above benefits have long been well known since Machines with horizontal rotating drum sieve is widely applied in our country before. Domestic researchers in the middle of last century are well substantiated theory and studied the practice of their work. However, in view of the design features of the surface area of the sieve of these machines use only 30%. Therefore, when identity performance are more bulky compared to machines from other types considered. Specified argument was sufficient reason for the disappearance of such machines in the country in recent decades, the Soviet period. However, in European countries such machines are manufactured to date, companies such as «Cimbria», Denmark, «Denis», France and successfully used by grain processors throughout the world. Now we have time to read. In our view, the modernization and the introduction of machines of this type of lie is the best deal on the equipment of the modern domestic agriculture and processing reliable, simple, effective and inexpensive means of cleaning the grain.

Our company, possessing the necessary scientific, technical and industrial potential, specializes in developing and implementing technology and machinery for grain processing. Therefore, as a result of research searching our specialists have found effective ways to increase utilization of the surface area of sieve separators with horizontal rotating drums in 1,5 times. Mentioned innovations have been a grave reason to create a sieve-air separator is a new level. In addition, the creative elaboration of the experience of air separation are also allowed to find their rational grain. As a result we have created the design of a sieve-air separator “BEAM SBV, which by virtue of the above-mentioned reasons for effective and productive counterparts.

Our company has developed and put into batch production range of separators with different productivity (Photo). Their specifications are listed in the table.

Photo. General view of the separator RAY SBV

Specifications:

Model |

Number of sections Sieve drum unit |

Diameter Sieve drum, mm |

Power of electric motors, kW |

Dimensions, mm |

Weight, kg |

Cleaning food grains, tons per hour |

Thorough cleaning from small grains, t / h |

Calibration of seed material, t / h |

ЗСО-25 |

3 |

630 |

7,35 |

3400 х2000 х3290 |

1674 |

25 |

10 |

5 |

ЗСО-40 |

4 |

630 |

7,35 |

4155 х2000 х3345 |

1924 |

40 |

25 |

6,5 |

ЗСО-50 |

3 |

900 |

8,1 |

3400 х2355 х3590 |

2600 |

50 |

30 |

7,5 |

ЗСО-75 |

4 |

900 |

8,1 |

4165 х2345 х3500 |

2700 |

75 |

50 |

10 |

ЗСО-100 |

3 |

1260 |

12,6 |

4500 х2820 х3975 |

3550 |

100 |

50 |

15 |

ЗСО-150 |

4 |

1260 |

12,6 |

5565 х2675 х4050 |

4350 |

150 |

100 |

20 |

ЗСО-200 |

5 |

1260 |

19,6 |

6650 х2780 х4060 |

5670 |

200 |

150 |

25 |

ЗСО-300 |

5 |

1600 |

23,1 |

6650 х2970 х4385 |

6700 |

300 |

200 |

30 |

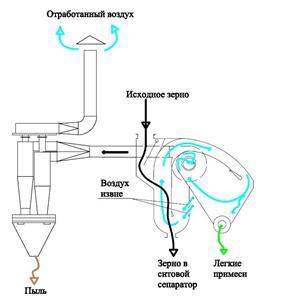

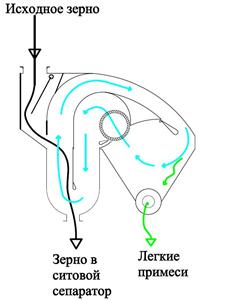

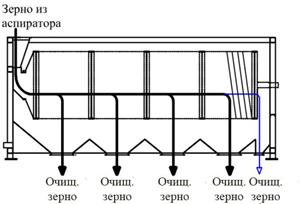

Separators can be equipped with air separator as a closed and with open-loop air flow (Figure 1). When a closed loop air from the working area enters the sediment chamber, where it is cleared from the blown impurities and fed back into the work zone. Separation of impurities are ejected through the valve screw conveyor. The air is driven by a built-in car fan. Thus, air is used repeatedly without supplying him into a car outside and released into the atmosphere, and the separator has a compact form without ductwork and extra parts. With open-loop air into the work area comes from the outside, and after cleaning is released into the atmosphere. Cages with open-loop air also contain sediment chamber, which separates large impurities. However, to avoid dust emissions from the exhaust air must, without fail, to go further purification. Separators of this type structurally simpler, but requires additional installation of cyclones and fans. Typically, such separators are used, if necessary, the selection of very fine particles and dust. When designing separators attention was paid to ensure the reliability of mechanisms to regulate air modes, as well as the convenience of visual inspection performance.

Fig. 1 Scheme of purification of grain in an air separatorAir separator with an open-cycle air

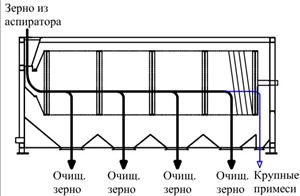

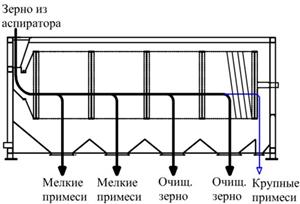

Cleaning grain sieve cylinder available at several of the most frequently used scheme (Figure 2). The design features of sieve separator should include the fact that the drive gear-motor mounted directly on the drum shaft and equipped with a shock of jet thrust. This decision greatly simplified the design of the drive, increasing reliability of the product. Shaft of the drum is fully collapsible and, if necessary, as all the other nodes in the drum can be removed from the car in parts. To ensure the tilt axis of the drum to the shaft mounted in special bearings made outside the working area that allows you to monitor their condition, even during work, and protects from dust. Developed and implemented a new reliable method of securing screens is simple and designed to use conventional perforated canvases in standard sizes, does not require the pre-padding on the frame or mount them any hooks, clips, etc. Replacement of all screens, even on the separator of the largest size is performed by two workers for time not exceeding one hour. Special design of fixing elements of cleaning screens automatically adjusts to any angle of inclination of the drum, and “floating” their suspension ensures high cleaning efficiency.

Fig. 2 Arrangement of clean grain in sieve separator

The electrical part of separators made in accordance with the requirements of the security elements in IP54, contains all the necessary locks for security personnel, as well as an immediate stop in case of emergency operating modes. When equipped separators we made for the use of bearing assemblies, actuators and electrical components only European manufacturers with high reputation, which eliminates random breakdowns and repairs.

Thus, the sieve-air separators “RAY SOA” is a worthy replacement set exhausted their resource grain cleaning machines on the currents, elevators and other grain processing facilities, as well as a decent alternative to the obsolete types of equipment when creating new industries.