Vereshchinsky A.L., Candidate of Technical Sciences, General Director of OLIS LLC

One of the effective methods of preparing wheat for grinding is peeling. As a result of peeling treatment, the ash content and strength of the grain, the content of impurities are reduced, and the prerequisites for effective conditioning are created. This ensures an increase in the quality of flour and its overall yield. and mainly due to high-grade flour.

The anatomical features of the structure of wheat grain determine strong connections between all grain shells, as well as between the shells and the endosperm. Taking this into account, the most effective method of peeling wheat grain is abrasion and shear, which is ensured by processing in hulling and grinding machines with an abrasive rotor. These machines have long been widely used for peeling grain of various crops during processing into cereals. However, despite this, there is no information in the existing literature about the properties and features of the interaction of their main working bodies – grinding wheels in relation to grain processing, which limits their rational use.

Based on the existing experience in the creation and operation of peeling and grinding machines, the most preferable for their abrasive rotors is the use of commercially produced straight profile grinding wheels (Type 1 – according to GOST 2424-83) on a ceramic bond with different outer diameters.Regulatory documentation provides for various characteristics of the material of such wheels, which include the grade of grinding grain, grain size (i.e., the size of the grinding grain), wheel hardness and the number of the wheel structure (the degree of convergence of the grinding grains). In table Table 1 shows the characteristics of grinding wheels used for grain processing, taking into account the currently produced nomenclature.

Table 1. Characteristics of grinding wheels according to GOST 2424 – 83, GOST 3647 – 80 (ISO 8486]

| Profile | Brand grade | Grit | Hardness | Structure number | Bundle |

| Type 1 | 14A, 25A, 54C, 64C | 16, 25, 40 (F80, F60, F46) |

SM1, SM2, C2, ST1, ST2, T1 (K, L, N, O, P, R) |

6,7 | K (V) |

The study of the properties of grinding wheels was carried out using a laboratory hollendr, the design of which made it possible to change the characteristics of the material of the grinding wheels by replacing them, to process grain samples of different initial masses Mref for different periods of time t, measure the drive power spent on peeling Nw, and also separately obtain processing products to calculate the grain peeling index k and further study their quality.

As a result of exploratory studies, it was found that the interaction of the working surface of grinding wheels with grain is characterized by several modes and corresponding states of the grain mass. The boundaries of the existence of the observed modes depend on many factors, the determining one of which is the mass of the initial grain sample Min, which determines the degree of filling of the working area of the device. At low values of Mout, but sufficient to fluidize the grain mass under the action of a rotating rotor, its state is characterized as scattered movement of individual grains. In this case, a low intensity of peeling and uneven surface treatment of the grains are observed, some of which acquire characteristic damage to the ends or are crushed. The contact of grains with the working surface of grinding wheels is short-term. It is obvious that in this case the radially directed components of the interaction forces prevail over their components directed tangentially to the working surface of the rotor. The drive power Nw, spent on implementing such a mode, is extremely insignificant and is within the idle speed values of the device. The considered mode does not provide effective peeling and cannot be recommended for practical use.

Increasing Mout to certain values leads to a qualitative change in the nature of the interactions of the working surface of the grinding wheels with the grain. The flow of the fluidized grain mass is compacted, the values of the directional interaction forces increase, the grains are “captured” by the working surface of the circles, which causes longer phase contact. This mode is characterized by a sharp increase in peeling intensity, drive power Nw, uniformity of surface treatment of grains, while their damage is reduced to negligible values. The specified processing mode should be considered effective.

Further increase in the Mout values in the effective peeling mode range leads to a further increase in the peeling intensity and drive power Nw. When certain values of Mout are reached, the grain mass loses its mobility and fluidized state, causing the rotor to jam. This mode should be characterized as emergency.

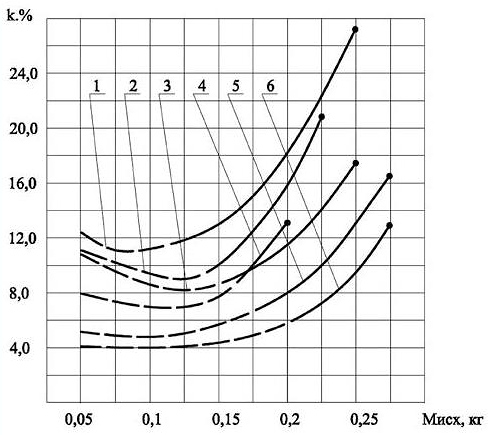

Fig.1. Dependency graphs: k = f(Mout) at t = 100 s.

1 – F46 14A SM1, V р = 17 m/s, W = 12.4%;

2 – F46 14A SM1, Vр = 17 m/s, W = 16.9%;

3 – F60 25A SM1, Vr = 17 m/s, W = 12.4%;

4 – F60 25A SM1, Vр = 17 m/s, W = 16.9%;

5 – F46 14A SM1, Vр = 11 m/s, W = 12.4%;

6 – F60 14A SM1, Vр = 11 m/s, W = 12.4%;

Figure 1 shows graphs of the dependences k = f(Mout), determined for wheels with different material characteristics when working under different conditions. The section of each curve, made by a broken line, characterizes an ineffective peeling mode, and the sections indicated by a solid line correspond to an effective peeling mode. The end points of the curves correspond to the maximum possible values of Mout range of the effective peeling mode, followed by emergency jamming of the rotor.

It should be noted that the degree of filling of the working area, modeled in this case by changing the mass of the initial sample Mind, in continuous peeling and grinding machines can be quickly an adjustable parameter, which is ensured by the design of the machine. Therefore, in production conditions, setting an effective peeling mode, as well as ensuring its functioning at any point in the range, should be a quickly solvable task.

Based on the possible modes of interaction of the working surface of grinding wheels with grain, further studies were carried out in the mode recognized as effective.

As a result of research, it has been established that during the operation of grinding wheels the nature of their working surfaces changes, which is associated with the presence or absence of a self-sharpening effect, similar in nature to self-sharpening when grinding metals. The presence of the self-sharpening effect and its intensity depend on the characteristics of the material of the circles and their operating conditions, which determine the magnitude and nature of force interactions. Thus, after dressing, the working surface of the grinding wheels is characterized by micro-roughness, determined by the size of the grinding grains (grain size) and the degree of their convergence, specified by the structure number. However, during the process of self-sharpening, irregularities are formed and developed on the working surfaces of the wheels that exceed the linear dimensions of the grinding grains and the distances specified by the structure of the wheels. When peeling grains, the working surfaces of the grinding wheel experience repeated scattered impacts of the grains, which leads to loosening and separation of entire agglomerates of grinding grains, with the formation of a new surface by agglomerates attached to the wheel. Thus, the nature of the interaction of the grain with the working surface of the wheels is determined not by individual grains that form a smooth surface, as when grinding metals, but by their agglomerates, which create macro-roughness. This property is the main feature of the self-sharpening of grinding wheels and their operation during grain peeling.

In the absence of a self-sharpening effect, the grinding grains of the working surface lose their cutting ability (become dull) without subsequent separation from the wheels. In the absence of regeneration of the working surface, the circles lose their functionality with the cessation of the peeling process. Due to the lack of practical value, studying the properties of wheels and the features of their interaction with grain outside of self-sharpening conditions is not advisable.

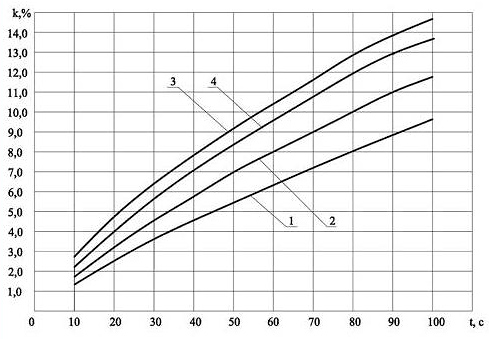

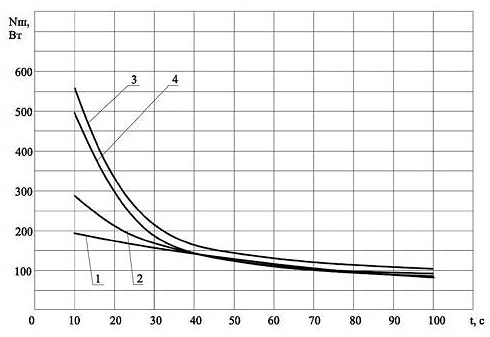

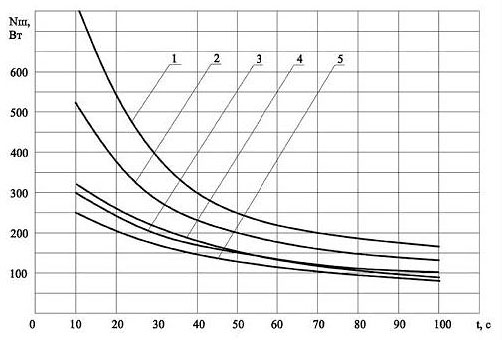

Our observations have shown that during self-sharpening over a certain period (period of increased performance), the working surfaces of newly dressed wheels gradually acquire macro-roughness, which reaches maximum values and is determined by the operating conditions of the wheels. These changes are accompanied by an increase in peeling intensity and drive power Nw with the achievement of maximum values and their stabilization during the subsequent period of operation. Figure 2 shows graphs of the dependences k = f(t) and Nw = f(k), obtained at different operating times T for the circles. Curves 1 and 2 correspond to the period of increased performance of the circles, and curves 3 and 4 correspond to the period of their stable operation under the tested conditions. The period of stable operation of the wheels ends with a period of decreased performance and its complete loss as a result of wear, characterized by a change in the initial profile of their working surfaces and a reduction in diameter to critical values.

Fig. 2. Dependency graphs: a) k = f(t); b) Nw = f(t).

25A F60 CM1; Mout = 0.25 kg; Vр = 11.0 m/s. 1 – T1, 2 – T2, 3 – T3, 4 – T4; T1<T2<T3<T4.

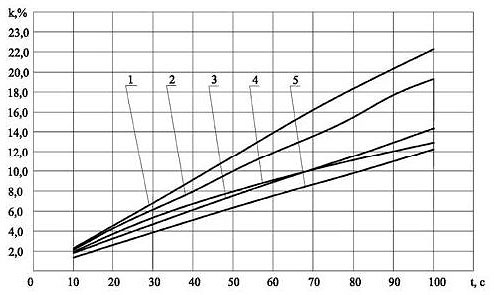

Fig.3. Dependency graphs: a) k = f(t); b) Nw = f(k).

Mref = 0.25 kg; Vр = 11.0 m/s.

1 – 64C F46 CM1; 2 – 64CF60 CM1; 3 – 64CF80 CM1;

4 – 14A F60 SM1, 25A F60 SM1; 5 – 64CF46 CT1.

It has been established that the duration of the periods defined above, the resource and quantitative indicators of the operation of grinding wheels depend on the intensity of the self-sharpening process. The specified properties of grinding wheels are determined by their hardness and grain size, and also depend on the brand of grinding grain. In Fig. Figure 3 shows graphs of the dependences k = f(t), determined for grinding wheels of different grain size, hardness and with different grades of grinding grain during a period of stable operation under identical conditions. As can be seen from the presented graphs, wheels of lower hardness and larger grain size with grinding grain grades 54C and 64C correspond to a higher peeling intensity. These wheels are characterized by a more developed macro-roughness acquired during the self-sharpening process, which is explained by the lower strength of the grinding grains in them. In addition, the agglomerates of the grinding grains of such wheels have sharper edges due to shorter periods of operation. 54C and 64C grades of abrasive grits are harder than 14A and 25A grits and have more angular and sharper edges, so their agglomerates maintain high cutting ability for longer working hours.

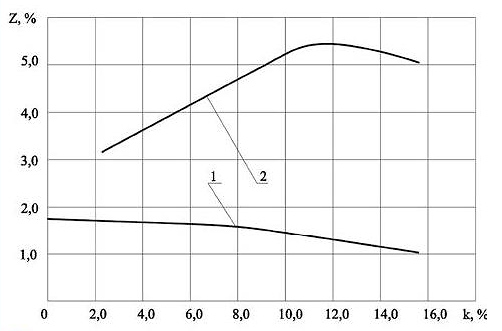

Fig.4. Dependency graphs: z = f(k).

14A F60 CM1; Mout = 0.25 kg; Vр = 11.0 m/s.

1 – grain; 2 – shells.

The influence of the characteristics of the material of grinding wheels on the quality of grain processing was studied by determining the ash content of peeling products, as well as the increment in the number of injured grains. The research results allowed us to conclude that with an effective peeling mode, the only significant factor determining the ash content of peeling products is the value of the peeling coefficient k (Fig. 4). This pattern is explained by the absence of hard contact of the working surface of the grinding wheels with the grains, which are in a fluidized state during the processing process. Thus, the impact of agglomerates of grinding grains, which differ as a result of self-sharpening in the size and sharpness of the edges, does not lead to an excessive depth of their penetration into the surface layers of the grains. However, an analysis of the fractional composition of shell particles (Table 2) indicates that the use of grinding wheels with a higher intensity of self-sharpening, and therefore with a more developed macro-roughness of the working surface, ensures the separation of shells into larger parts. The increase in the number of injured grains over the entire range of effective peeling mode is insignificant and does not exceed 0.5%.

Table 2. Fractional composition of shell particles

| Circle material | Passage of sieve No. 43, % k=3.2%; W=11.6%. |

Passage of sieve No. 43, % k=8.9%; W=11.6% |

Passage of sieve No. 43, % k=3.2%; W=16.4% |

Passage of sieve No. 43, % k=3.2%; W=16.4% |

| 25A F80 CM1 | 57.8 | 73.6 | 42.8 | 59.4 |

| 25A F60 CM1 | 54.4 | 71.3 | 37.3 | 52.1 |

| 25A F46 SM1 | 51.1 | 68.7 | 34.2 | 46.8 |

The completed research allows us to formulate a number of practical conclusions:

- To ensure grain processing within the range of the effective peeling mode, hulling and grinding machines with an abrasive rotor should be equipped with means of operational control of the degree of filling of the working area – a feeding device for supplying the initial grain to the machine and a device for removing the processed grain from the machine, synchronized with it in terms of productivity.

- The selection of the characteristics of the wheel material, ensuring a rational intensity of peeling and an interconnected service life, must be carried out experimentally for each specific operating conditions, taking into account the patterns outlined above.

- Ensuring a reliable self-sharpening effect and shortening the period of increasing the performance of new wheels is possible by first artificially creating macro-roughness on their working surfaces during the dressing process.

- The absence of a practically significant influence of the characteristics of the material of grinding wheels on the quality of grain processing gives grounds to assert that in production conditions, ensuring a rational intensity of peeling and service life of grinding wheels is a sufficient condition for choosing the characteristics of their material.

Published based on materials

“Grain storage and processing”

scientific and practical journal

№11 (149) November 2011