Vereshchinsky A.P., Candidate of Technical Sciences, General Director of Olis LLC;

Shevchenko A.V., process engineer at Olis LLC

According to the recommended standards [1], grain supplied to flour mills should contain no more than 2% of impurities (if there is equipment for grain processing at the elevator – no more than 1%) and not more than 5% grain impurity. At the same time, the maximum permissible content of impurities in grain sent to the first torn system for baking wheat grinding should not exceed 0.4%, and grain grain is not regulated.

However, grinding practice shows that increasing the quality and yield of flour, especially high grades, requires more significant extraction of impurities. An analysis of the results of the work of two mills over several years shows [2] that with an increase in the content of weeds by 0.1% in the grain before the I torn system, the total yield of flour decreases by approximately 1.4%, or the weighted average ash content of flour increases by approximately 0 .04%. An increase in the content of grain impurities in purified grain by 1% leads to a decrease in the total flour yield by approximately 0.8%, or an increase in the weighted average ash content by 0.15%. Researchers have determined that among all the quantities that influence the yield of flour during varietal grinding, 55% is accounted for by the residual content of weeds and grain impurities in the grain before the first grinding system.The data presented clearly illustrate the importance of grain cleaning when preparing it for grinding and the need to find ways to increase its efficiency. It is obvious that the standards for the content of impurities in grain sent to the preparation department of the mill and then to grinding are adopted taking into account the capabilities of modern cleaning technology.

This means that, despite the wide arsenal of means used (separators, concentrators, combiners, trieres, beakers), modern methods of grain cleaning using complex and expensive machines, as well as substantial resources are not always able to ensure high efficiency. Thus, the search for ways to improve the efficiency of grain cleaning should be carried out outside of existing approaches.

As you know, one of the effective methods of preparing grain for grinding is peeling. The main influencing factor of such processing is considered to be a decrease in the ash content of grain due to a decrease in the specific content of the shells. However, it has been noted that the result of such treatment is also a reduction in the content of impurities, i.e. The peeling process has a cleaning effect. As a result of peeling, the grain mass is subjected to abrasion and shear, as well as interaction with air currents. Therefore, the destruction of particles with lower strength characteristics, which apparently include a significant part of the impurities, and their removal from the grain mass is a completely natural result. However, to date there is no scientifically based data on the effectiveness of such cleaning and the advisability of its use in preparing grain for grinding.

The patterns of grain purification during the peeling process were studied using a laboratory hollendr, which allows processing grain samples with different impurity contents to the required values of the peeling index k, as well as separately obtaining the main grain and separated particles. In addition, to obtain comparative estimates, the content of impurities separated by the most common and effective sieve-air grinding method in each initial test sample was determined. Sifting of samples was carried out using laboratory sieving on sieves 4×25 and 1.7×20 until complete extraction of passing fractions. Pneumoseparation was carried out in a laboratory aspirator by repeated passes until the impurities released by the air flow were completely removed. During the experiments, the initial and final content of impurities was determined using standard methods, and the purification efficiency was calculated.

The study of samples selected from batches of wheat grain supplied to the mills of a number of enterprises in Ukraine allows us to conclude that the efficiency of purification by the sieve-air method in isolating impurities is about 55%, and grain – about 32%.

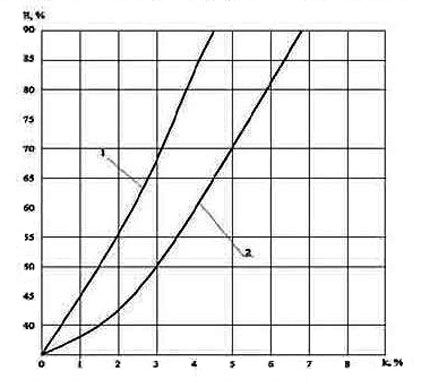

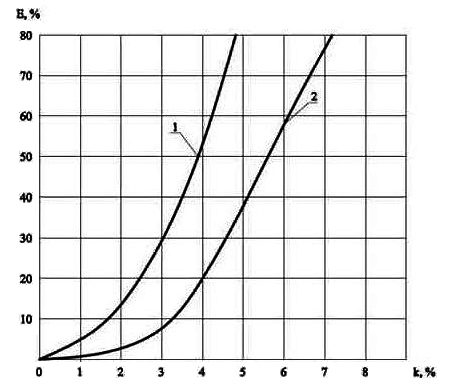

Generalized results of the efficiency of grain cleaning E during the peeling process when installing sieve shells on the hollendr with opening sizes of 1.3×12 and Ø2 mm, which exclude small grains from entering the waste, are presented in Fig. 1 and 2.

Fig.1. Graphs of the dependence of the efficiency of grain cleaning E on the peeling index k for the release of weeds:

1 – sieve shell with holes 1‚3×12 mm;

2 – sieve shell with holes Ø2 mm

Fig.2. Graphs of the dependence of grain cleaning efficiency E on the peeling index k for the release of grain impurities:

1 – sieve shell with holes 1‚3×12 mm;

2 – sieve shell with holes Ø2 mm

From the analysis of the presented data it follows that peeling with indices k = 2-3.5% in terms of efficiency of weed release, and peeling with indices k = 3-4.5% in the separation of grain impurities is identical to cleaning using a sieve-air method. A further increase in peeling indices k leads to a further significant increase in cleaning efficiency.

As can be seen from the graphs, grain cleaning by peeling, especially from impurities, is more effective using a sieve shell with elongated holes, which were located along the direction of rotation of the abrasive rotor. The observed effect is explained by the higher throughput of the shell with oblong holes for removing small particles formed by peeling from the grain mass.

It should be noted that with k index values of more than 5%, when the grain mass of wheat is peeled, the barley grains present lose the flower, as well as partially the fruit and seed shells, which are released into waste. The exclusion of these anatomical parts of barley ensures that they do not have a negative impact on the grinding results.

When processing the wheat grain mass by peeling, the present wild oat grains, which are a difficult to separate impurity, are partially destroyed and released. The remaining part of the wild oat grains after peeling is characterized by tears and peeling of the shells, which reduces the rate of soaring of the grains, which facilitates their separation from the wheat grain by subsequent pneumatic separation.

The results of the studies show that the peeling of wheat grain mass is highly efficient in cleaning. The effect of peeling as an operation to prepare grain for grinding can be used as a complement to existing methods, as well as an alternative and replacement method. Thus, the use of peeling in grinding practice can significantly increase their efficiency, and also, in some cases, eliminate the use of complex, expensive and resource-intensive machines.

Published based on materials

“Grain storage and processing”

scientific-practical journal

№7 (157) July 2012

- Rules for organizing and maintaining the technological process at flour mills. – K.: Kiev Institute of Bread Products, 1998. – 144 p.

- Fractional separation of grain at flour mills. Dulaev V.G., Gortinsky V.V., Alterman A.N., Gorshunov A.N., Muravin V.S., Bessonov V.Ya., Zotikov V.M., Fedorova A.N. Series “Flour-milling and feed industry”, – M; TSIITEI Ministry of Foreign Affairs of the USSR 1978. – 60 p.