A.P. Vereshchinsky, Ph.D. tech. Sciences, General Director of LLC “OLIS” (Odessa)

In varietal wheat grinding, groats formation, as a substage of the grinding process, determines the structure of all subsequent processing and significantly affects the quality and yield of flour. Therefore, improving grit formation is a primary goal in ensuring the effectiveness of varietal grinding. The main technical and technological requirements for the grain formation process are to obtain the maximum amount of intermediate products of the best quality with the least expenditure of energy and other resources.

In laboratory studies carried out earlier [1], it was established that grinding pre-hulled grain provides an improvement in the quality of intermediate products, an increase in the number of their large fractions, as well as a reduction in the energy intensity of grinding. Taking this into account, a subject of practical interest is to check the results of reducing the number of cereal-forming systems through the use of low grinding modes of hulled grain in the torn process. In this work, in the production conditions of a mill with a capacity of 30 tons/day. The effectiveness of the cereal formation process when grinding hulled grain, implemented through one system, was studied, as well as its influence on the final results of varietal baking wheat grinding carried out without enrichment.

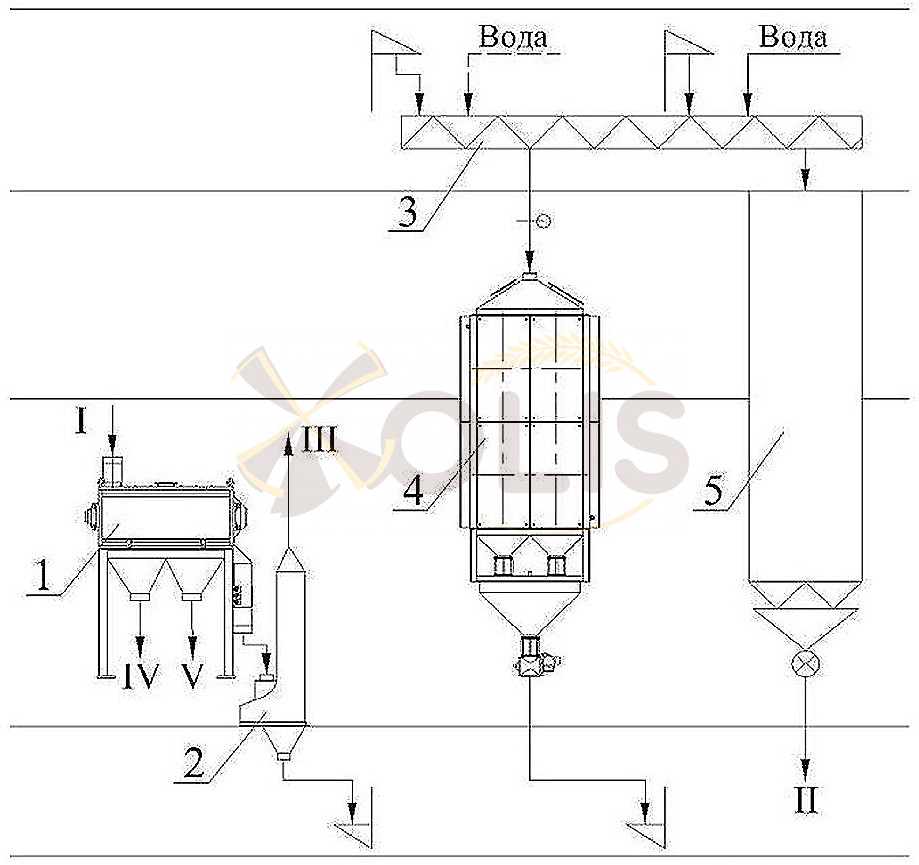

Wheat grain with a natural content of 782 g/l was supplied for processing., glassiness 45% and ash content 1.53%. After conditioning, the grain was hulled with a hulling index of 6.8% in hulling and grinding machines of the “Cascade” design [2], which ensured a reduction in its ash content to 1.27%. Grain grinding (Fig. 1) was carried out to ensure a total extraction on the I frayed system of 73.4% of the load on the hulling and grinding machines (78.8% of the load on the system). In addition to the roller machines on grinding systems II, 1 and 2, dismembrators with adjustable rotor speed were used.

Fig.1. Schematic flow diagram of the grinding stage

Analysis of the quantitative and qualitative indicators of intermediate products (Table 1) obtained on the first torn system showed that the main part of them is characterized by a sufficiently high quality factor, allowing further grinding without enrichment to produce flour High Quality. At the same time, large grains are characterized by a relatively high content of shell particles, which requires solving the problem of their enrichment. In this regard, sieves with opening sizes of 800 microns were installed in the first group of sieves in the screening section I of the torn system, which made it possible to direct part of the coarse grains with a reduced quality factor for further grinding in the torn process.Thus, on the first torn system, flour was selected (11.4/0.55), and coarse grains (7.1/0.8), medium grains (14.1/0.73) were also extracted and sent to the grinding process ), small grits (10.5/0.67) and duns (13.2/0.57). The total amount of intermediate products sent to the grinding process was 44.9% with an average weighted ash content of 0.66%. 37.0% of the waste product with an average weighted ash content of 2.22% was sent to the second torn system. When processing the specified product on a roller machine of the II torn system, ensuring a total extraction value of 34.7% of the system load, 8.5% of flour with an ash content of 0.64%, 8.7% dunst, as well as products of other fractions formed mainly shells. Taking into account the quantitative and qualitative results of grinding on a roller machine of the II torn system, the resulting product was subjected to further grinding. Thus, we can conclude that in this case the process of graupel formation is carried out on the I torn system, and the II torn system actually performs the function of cutting and threshing.

Table 1. Quantitative and qualitative indicators of grinding ensuring a total recovery of 73.4% per I dr.s. in % of the load on the peeling and grinding machines (output, % / ash content, %)

| Product | After the machine I torn system |

Before the machine II torn system |

After the machine II torn system |

| Ramp 1.0 | 19.9 / 2.68 | 19.9 / 2.68 | 6.9 / 4.05 |

| Large grains | 18.8 / 1.56 | 11.7 / 2.02 | 5.7 / 3.62 |

| Medium grain | 17.1 / 0.79 | 3.0 / 1.1 | 6.2 / 2.49 |

| Fine grains | 11.9 / 0.62 | 1.4 / 0.77 | 1.0 / 2.40 |

| Dunst | 13.4 / 0.58 | 0.2 / 1.26 | 0.7 / 1.20 |

| Flour | 12.2 / 0.57 | 0.8 / 0.85 | 8.5 / 0.64 |

According to the results of the grinding, 73.2% of flour was obtained, incl. premium flour 54.8% with whiteness 60 conventional units. units R3-BPL and first grade flour 18.4% with a whiteness of 43 conventional units. units R3-BPL. Taking into account the data obtained, we can conclude that carrying out the cereal-forming process even on one system at low grinding conditions for hulled grain allows one to obtain satisfactory grinding results and can be considered effective for milling plants without enrichment. In addition, reducing the number of grinding systems leads to a reduction in the capital intensity of creating such grinding plants, and also provides savings in energy and other resources during operation.

published in the publication “Bread Products” 6/2013

- Vereshchinsky A.P. Patterns of grinding hulled wheat grains [Text] / A.P. Vereshchinsky // Bread products. – 2012. – No. 12. – P.38-39.

- Vereshchinsky A.P. The effectiveness of “Cascade” hulling and grinding machines in the preparation of wheat grain in varietal grinding [Text] / A.P. Vereshchinsky // Bread products. – 2012. – No. 11. – P.40-41.