A.P. Vereshchinsky – General Director of LLC “OLIS”, Doctor of Technical Sciences;

D.V. Shevchenko – Head of the Development and Implementation Department of OLIS LLC

Development of the consumer market of goods determines the actual directions of improvement of technologies of their production. So, the analysis of modern conjuncture of the market of cereals shows a steady advantage in demand for split peas. Traditional technology of cereal production from peas provides for the production of split peas together with whole peas in a set proportion. The traditional technology does not provide for increasing the output of split peas, let alone the production of peas only split. In the arsenal of existing technological operations and machines for their implementation special means of solving this problem are absent. But practice shows that the development and use of new equipment can effectively meet this need, as well as provide a significant reduction in processing technology and reduce its energy intensity.

The traditional technology [1, 2] of pea husking uses machines of A1-ZSHN type. The necessary technological efficiency of their work is provided by the previous fractionation of pea grain with processing of coarse and fine fraction separately on two consecutive peeling and grinding systems. At the same time, tests of modern peeling machine design “Cascade” (Fig. 1) revealed the possibility of effective implementation of pea husking operation without pre-fractionation and on a single peeling and grinding system.

Fig. 1 Peeling and grinding machine of “Cascade”

Checking the efficiency of sorting of husked peas, obtained without prior fractionation of grain, showed that the use of sieves with oblong holes of size 4×20 and even 4.2×20 reliably provides a complete separation of peas chopped in the passing fraction and excludes getting into its composition of small peas whole.

Thus, the introduction of peeling and grinding machines of “Cascade” design in pea processing technology allows to completely eliminate the fractionation operation, and instead of four peeling systems to provide only one.

A centrifugal-type impact machine of the MKG brand was developed for grinding whole peas into seeds (Fig. 2). The named machine consists of a rotor, providing acceleration of a grain to a certain speed, and a reflecting ring with a surface of a special profile. Tests of such a machine showed that intensification of pea grinding by increasing the rotor speed necessarily entails an increase in the content of flour and crushed peas. Therefore, for each batch of peas it is necessary to choose the most acceptable mode of grinding, the resulting mixture is sorted, and the separated whole peas should be sent for re-milling.

Fig. 2 Machine for grinding whole peas into seed pods of MKG

Traditional pea processing technology [1, 2] includes polishing of husked peas, both whole and pounded. Carrying out such operation slightly improves the commodity appearance of groats, but does not affect the increase in its nutritional value and leads to an increase in cost. Under these conditions, polishing pea groats is not a prerequisite for their successful sale and, as practice shows, in most cases can be excluded.

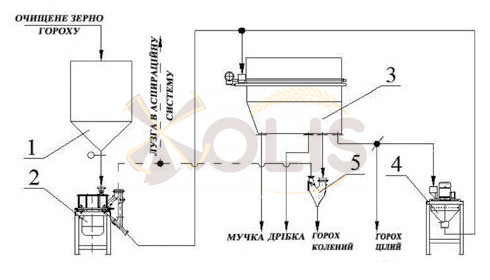

The above innovations are fully realised in the development of the technological scheme (Fig. 3) of pea groats production for universal groats workshops of small capacity “OPTIMATIK-K”. The named groats production units with productivity of 7 and 15 tonnes/day are serially produced by LLC “OLIS” with the use of Ukrainian patent for invention [4]. The experience of work of a number of such production facilities shows that the actual yield of whole peas and split peas is provided in the range of 83- 85%, and when receiving only split peas – 80-82% in relation to the grain after grain cleaning. At the same time, the cost of electricity for processing 1 tonne of grain is 32-34 kWh!

According to the scheme shown in Fig.3, it is possible to create pea processing of any productivity with the use of equipment of greater capacity than we have in our arsenal.

Fig. 3 Principal technological scheme of pea groats production,

which is realised in universal grits grinding machines “OPTIMATIK-K”:

1 – hopper; 2 – peeling and grinding machine of “Cascade” design 3 – PG sifter;

4 – machine for pea seedling grinding MKGG; 5 – aspiration column AK

As it is known, seed pods in pea grain make up 90-94% of its weight [2], therefore, even taking into account the above results, further search for means to increase the yield of groats from peas is relevant and promising.

LITERATURE

-

- Kroshko G.D. Rules of organisation and conduct of technological process at large’yanichnyh plants [Text]/G.D. Kroshko [and others]. – K.: “Vipol”, 1998. – 145 p.

- Shutenko Є.І. Technologiya krup’yanogo vroobniztva [Text] / Є. І. Shutenko, S.M. Sots. – K.: “Osvita Ukrainy”, 2010. – 272 c.

- Universal grits processors “OPTIMATIK-K- 07” and “OPTIMATIK-K- 15” [Electronic resource]. – Access mode: www.olis.com.ua

- Patent No. 99424 Ukraine, B02B 3/02 (2006.01). Installation for knee pea production [Text]/O.P. Vereshchinskiy. Vereshchinskiy; patentslasnik Vereshchinskiy O.P. – No. a 2011 13880; avv. 25.11.2011; published 10.08.2012 ; Bulletin No. 15. – 4 p.