A.P. Vereshchinsky, Ph.D. tech. Sciences, General Director of LLC “OLIS”, Odessa;

M.S. MUSIC, process engineer at OLIS LLC, Odessa;

A.V. SHEVCHENKO, process engineer at OLIS LLC, Odessa

This article provides ways to improve the preparation of wheat grain for high-quality baking grinding. A technological scheme for grain conditioning using pre-husking and heating has been proposed.

Compared with hot methods of water-heat treatment (WHT), the cold method does not require expensive and complex equipment using steam, vacuum or excess pressure, as well as energy costs due to the need to heat the grain to a temperature of 50…70 °C. These advantages have led to the use of exclusively cold air conditioning in modern economic conditions. However, the implementation of the cold WTO method is complicated by the limited water absorption capacity of the grain when moistened, which in some cases requires this operation to be carried out in several stages with intermediate dampening. In addition, to ensure a technological effect during cold conditioning, long-term refrigeration of grain is necessary, which requires bins of significant capacity.Thus, in accordance with current recommendations [1], depending on the glassiness and initial moisture content of wheat, the increase in moisture during one stage of moistening does not exceed 3.5%, and the total recommended duration of dampening can exceed 24 hours. In addition, the low rate of moisture diffusion and biochemical processes observed at low grain temperatures during the cold and transition periods of the year prevents the full use of the technological potential of WTO. Heating grain to a temperature of 20…25 °C, despite its effectiveness, is not used in grinding practice at most flour mills. This is explained by the inappropriate choice of place for heating grain in the structure of preparing it for grinding [1], which reduces the efficiency of this operation. In addition, the common design of a grain heater [2] requires the use of steam, the provision of which creates significant difficulties in the conditions of most flour mills.

Thus, the development and practical use of effective methods for intensifying the cold WTO method is one of the promising ways to increase grinding efficiency.

Laboratory studies carried out earlier have established a significant increase in the increase and rate of spread of moisture deep into the pre-hulled grain [3], as well as an increase in the efficiency of cleaning the surface of the grain [4], and a decrease in the content of impurities [5], as a result of its peeling. Thus, peeling can be used not only as a grain surface cleaning operation, usually carried out before WTO in wallpaper machines, but also as a way to intensify WTO and additionally remove impurities. At the same time, processing wheat grain to ensure a hulling index above 3.0% leads to a sharp decrease in the viability of the grain and the active development of mold fungi on the surface of its grains under conditions of high humidity. The indicated value of the peeling index is an appropriate limit for grain processing, which can be carried out before WTO.

Analysis of typical structures [1] for preparing grain for grinding showed that the operation of heating grain is carried out at the very beginning of its preparation, that is, before the sieve-air separator.Thus, before conditioning operations, the heated grain passes through a number of machines (sieve-air separator, destoner, concentrator, wallpaper machine, aspirator), where it actively interacts with cold aspiration air coming from the working area of the premises and is cooled. It is obvious that heating of grain should be carried out immediately before moistening in heaters of simple design, using, for example, hot water as a heating agent, and cooling should be carried out in thermally insulated bunkers.

Thus, the purpose of this work is to test in practice the considered methods of intensifying WTO, increasing the efficiency of grain surface cleaning, additional removal of impurities and determining a rational technological scheme for their implementation.

From the practice of grinding it is known that, taking into account the milling properties of grain, satisfactory conditioning results are more difficult to achieve when processing grain with high glassiness and low humidity. At the same time, shortcomings in the conditioning of this particular grain have the most negative impact on the results of grinding, which in most cases is expressed by a decrease in flour yield, and especially a decrease in its whiteness. In this regard, these studies were carried out at flour mills in the southern regions of Ukraine and Russia, where the risks could be most manifested: Agrofirm Khlebnaya Niva LLC, AP Protos LLC (Odessa region), Olvia LLC (Nikolaev region region), LLC “Vector Plus” (Krasnodar region), SEC “Novobatayskaya” (Rostov region), working on local raw materials. The necessary operations were carried out using a wallpaper-husking machine of the MAO type [6] and a grain heater of the PZ type [7].

Based on the quality indicators of the available raw materials, the grain of the majority of the grinding batches studied was characterized by an initial glassiness of 55…70% and a moisture content of 11.0…12.5%. In table Table 1 shows the quality indicators of grain from one of the most typical grinding batches, which, after cleaning, enters a wallpaper-husking machine of the MAO type and is processed in it under different modes.

Table 1. Quality indicators of the original grain and those processed under different modes

| Indicator, % | Original grain | Mode 1 | Mode 2 | Mode 3 |

| Humidity | 11.6 | — | — | — |

| Vitreousness | 67 | — | — | — |

| Ash content | 1.63 | 1.55 | 1.54 | 1.54 |

| Weed content | 0.56 | 0.31 | 0.26 | 0.24 |

| Grain admixture content | 3.20 | 3.44 | 3.58 | 3.61 |

| Content of broken grains | 2.70 | 3.02 | 3.14 | 3.22 |

The quantitative characteristics of the modes established during the testing process, as well as the ash content of the separated products, are given in table. 2.

Table 2. Quantitative and qualitative characteristics of grain processing modes

| Parameter | Power consumption, kW/t | Wallpaper dust | Separated shells | ||

| Quantity, % | Ash content, % | Quantity, % | Ash content, % | ||

| Mode 1 | 2.36 | 0.30 | 12.65 | 1.5 | 4.68 |

| Mode 2 | 2.72 | 0.33 | 12.50 | 2.0 | 4.20 |

| Mode 3 | 3.04 | 0.38 | 9.01 | 2,3 | 4.22 |

During the entire test period, the specified grain treatment ensured its further stable moistening in one stage to a moisture content of 16.0…16.5% by dosing water with a rotameter and mixing in a screw conveyor, then eat without the use of intensive humidification machines. In addition, such processing of grain ensured reliable cleaning of its surface, as well as the removal of up to 60% of impurities. The content of grain impurities increased insignificantly due to a slight increase in broken grains. Based on the quantitative and qualitative indicators of the grinding results, it was established that the grain processing carried out by separating wallpaper dust and shells in an amount of 1.5…2.5% allows reducing the time of its cooling by 4…5 hours. With a standard defrosting duration of 16…20 hours, established for processed grain in accordance with current recommendations [1], the reduction in defrosting duration was about 25%. Similar results were obtained at other industries.

During the cold periods of the year, the grain arriving for conditioning was heated immediately before humidification in a PZ-type heater at a capacity of 1.0…1.8 t/h. per section. Taking into account the fact that in certain periods the air temperature in the preparatory department of flour mills dropped to 8…10 ° C, the quality and yield of flour corresponded to the indicators that were obtained from grain grinding batches of the same quality processed during the warm period.

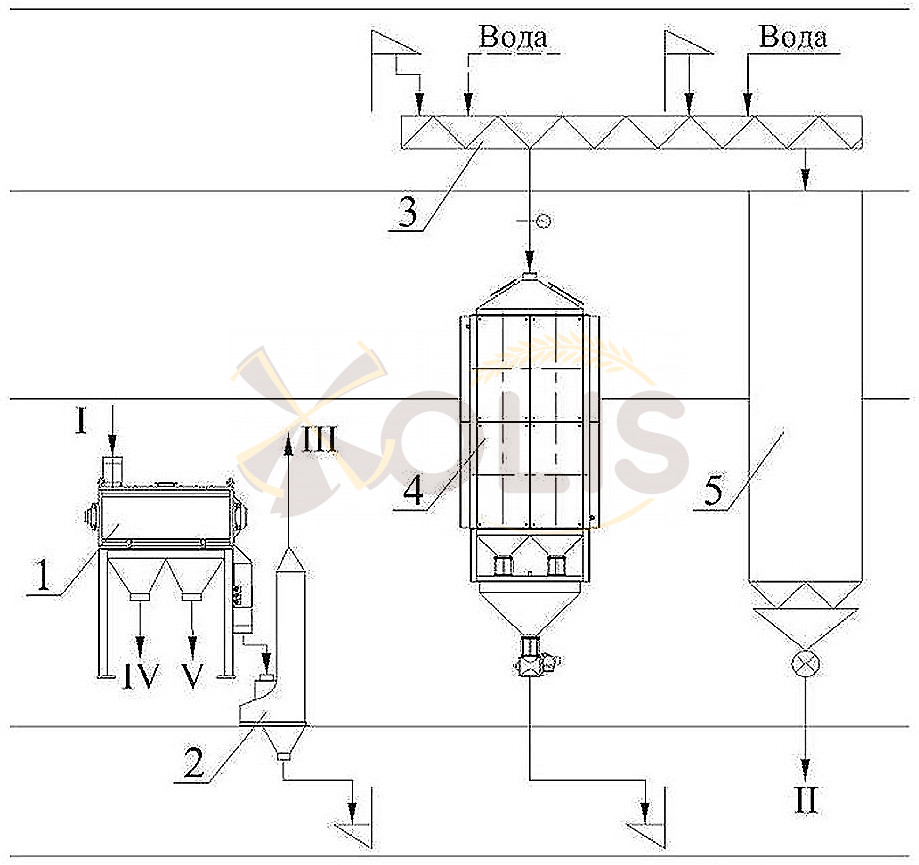

Fig.1. Recommended technological scheme of the WTO:

1 – MAO type wallpaper peeling machine; 2 – air separator type A1-BNA;

3 – screw conveyor; 4 – heater type PZ; 5 – thermally insulated dehumidification bunker

I – grain after cleaning; II – conditioned grain;

III – into the aspiration system; IV – wallpaper dust; V – bran.

Based on the results of production research, a technological scheme for implementing the WTO was proposed for implementation (Fig. 1). In addition to the above, such a technological scheme, if necessary (if the initial grain moisture content is less than 10.5…1 1.0%), allows, without significant changes, to additionally moisten the grain before the heating operation.It is obvious that the temperature gradient and humidity gradient, simultaneously directed deep into the grain during its stay in the heater shaft (about an hour), contribute to the rapid spread of moisture into the inner layers of the shells and the aleurone layer, which is characterized by high water permeability and hydrophilicity [8]. Thus, when re-wetting, the active surface of the grain in the form of capillaries and pores is again capable of absorbing (“capturing”) moisture.

- 1. Kroshko G.D. Rules for organizing and conducting the technological process at boron mills [Text] / G.D. Kroshko [ta in.]. – K: Vipol, 1998. – 145 p.

- Demsky A.B. Equipment for the production of flour, cereals and compound feeds [Text] / A.B. Demsky, V.F. Vedenev. – M: DeLi print, 2005. – 760 p.

- Vereshchinsky A.P. Peeling as a way to intensify water-heat treatment in varietal wheat grinding [Text] / A.P. Vereshchinsky, N.S. Music // Grain storage and processing – 2012. – No. 6 – P.38-40.

- Dudarev I.R. Scientific and technical foundations of process intensification and the creation of machines for grain surface treatment [Text]: dis. … dr. technical sciences / I.R. Dudarev. – Odessa, 1989. – 437 p.

- Vereshchinsky A.P. Cleaning grain from impurities during the peeling process during varietal grinding of wheat [Text] / A.P. Vereshchinsky, A.V. Shevchenko // Grain storage and processing – 2012. – No. 7 – P.36-37.

- Machines for cleaning the surface of grain [El. resource]

- Grain heaters PZ [El. resource].

- Egorov G.A. Technological properties of grain [Text] / G.A. Egorov. – M: Agropromizdat, 1985. – 333 p.