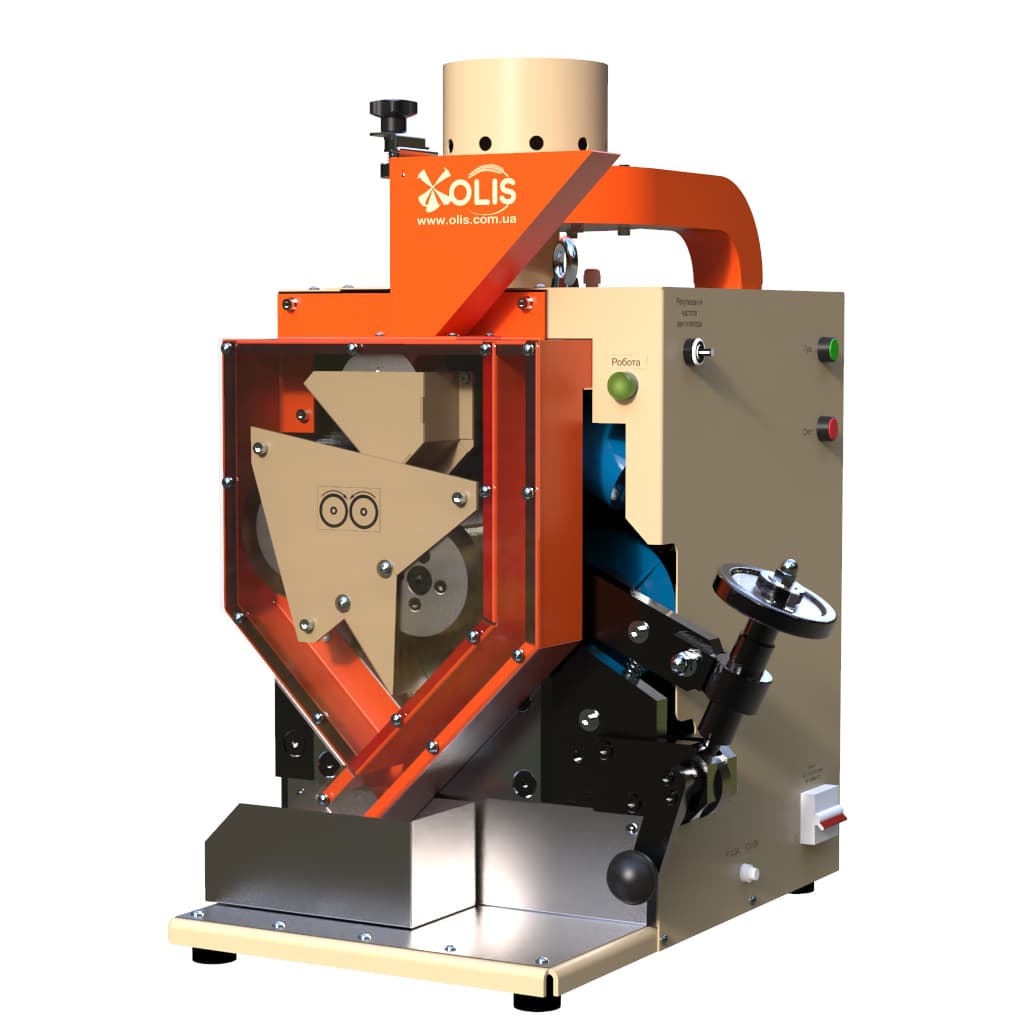

Laboratory Huller OLISLAB 3200

Purpose and scope:

Laboratory huller Olislab 3200 (for rice and millet), a modernized version of the PR-1 huller, roll type, designed for mechanization of labor-intensive processes of grain hulling and separation of hulling products, when determining hull content; fractures of rice-grain; the content of spoiled, red, glutinous and yellowed grains in raw rice; content of spoiled grains in millet.

With the help of the device, the process of grain hulling is realized according to the principle of action of compression and shear deformations between rubber-coated rolls with the formation of hulling products in the form of hulls.

It is used in grain processing enterprises, feed mills, variety testing breeding stations and research laboratories.

For a standardized determination of the cereal properties of grain according to DSTU ISO 6646:2003 / ISO 6646:2000 / “Rice – Determination of the potential milling yield from paddy and from husked rice”; ISO 6646:2011 “Rice – Determination of the potential milling yield from paddy and from husked rice”; as well as for use in other methods according to domestic and international standards.

Description:

The device consists of the body, the front panel with an indicator board and control buttons placed on it, the electric motor, the roller with rubberized rollers, the loading funnel and the aspiration channel.

Ideal for hulling hulled grain crops, which have a strong kernel, and the outer hulls cover the core without growing together with it – rice, millet.

Principle of operation: the initial product from the loading hopper is evenly fed into the working chamber with the help of the feed roll, where the grain come into contact with rubberized working rolls rotating towards each other at different speeds. Hulling waste in the form of hulls enter the pneumatic channels and are directed to the dust collectors with the help of the oncoming air flow. The cleaned kernels of grain crops are deposited in a separate collection of clean grain. The degree of grain hulling is controlled by changing the size of the roll gap. The degree of cleaning grain from waste is regulated by the speed of rotation of the fan that forms the air flow.

Specifications

| Model | OLISLAB 3200 |

| Type | roll |

| Loading hopper volume, cm3 | 680 |

| Roll size: | |

| diameter, mm | 120 |

| length, mm | 60 |

| Roll speed: | |

| – rapidly rotating, vib./min | 960 |

| – slowly rotating, vib./min | 510 |

| – warm-up, vib./min | 56 |

| Fan speed, vib./min | 0…25000 |

| Protection class against electric shock | I |

| Network type | 3N~ |

| Power supply: voltage / frequency, V / Hz | 380±38 / 50 |

| Power consumption, W | 2650 |

| Overall dimensions L × W × H, | |

| – in working condition, mm, not more | 700 × 520 × 750 |

| – in transport condition, mm, not more | |

| Net weight / gross weight, kg | 130 / |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – relative humidity, % | 60 ± 15 |

Аdvantages

ADJUSTMENT ACCURACY

Convenient adjustment of the inter-roll gap due to the presence of a halt / dump system for the rolls.

Adjustment of the feed rate of the product into the working area using a screw pair.

Infinitely adjustable air flow.

ERGONOMICS

Possibility of visual observation of the hulling process.

VERSATILITY

Can be used for:

– settings of technological equipment and scientific substantiation of the construction and modes of processes: hulling, moisture heat treatment;

– evaluation of cereal properties of grain.

SAFETY AND DURABILITY

Presence of the aspiration column with the cyclone and the filter.

Device resource before the first average repair is 10 thousand hours.

The service life of the device is 10 years.

Photo

| Model | OLISLAB 3200 |

| Type | roll |

| Loading hopper volume, cm3 | 680 |

| Roll size: | |

| diameter, mm | 120 |

| length, mm | 60 |

| Roll speed: | |

| – rapidly rotating, vib./min | 960 |

| – slowly rotating, vib./min | 510 |

| – warm-up, vib./min | 56 |

| Fan speed, vib./min | 0…25000 |

| Protection class against electric shock | I |

| Network type | 3N~ |

| Power supply: voltage / frequency, V / Hz | 380±38 / 50 |

| Power consumption, W | 2650 |

| Overall dimensions L × W × H, | |

| – in working condition, mm, not more | 700 × 520 × 750 |

| – in transport condition, mm, not more | |

| Net weight / gross weight, kg | 130 / |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – relative humidity, % | 60 ± 15 |

ADJUSTMENT ACCURACY

Convenient adjustment of the inter-roll gap due to the presence of a halt / dump system for the rolls.

Adjustment of the feed rate of the product into the working area using a screw pair.

Infinitely adjustable air flow.

ERGONOMICS

Possibility of visual observation of the hulling process.

VERSATILITY

Can be used for:

– settings of technological equipment and scientific substantiation of the construction and modes of processes: hulling, moisture heat treatment;

– evaluation of cereal properties of grain.

SAFETY AND DURABILITY

Presence of the aspiration column with the cyclone and the filter.

Device resource before the first average repair is 10 thousand hours.

The service life of the device is 10 years.