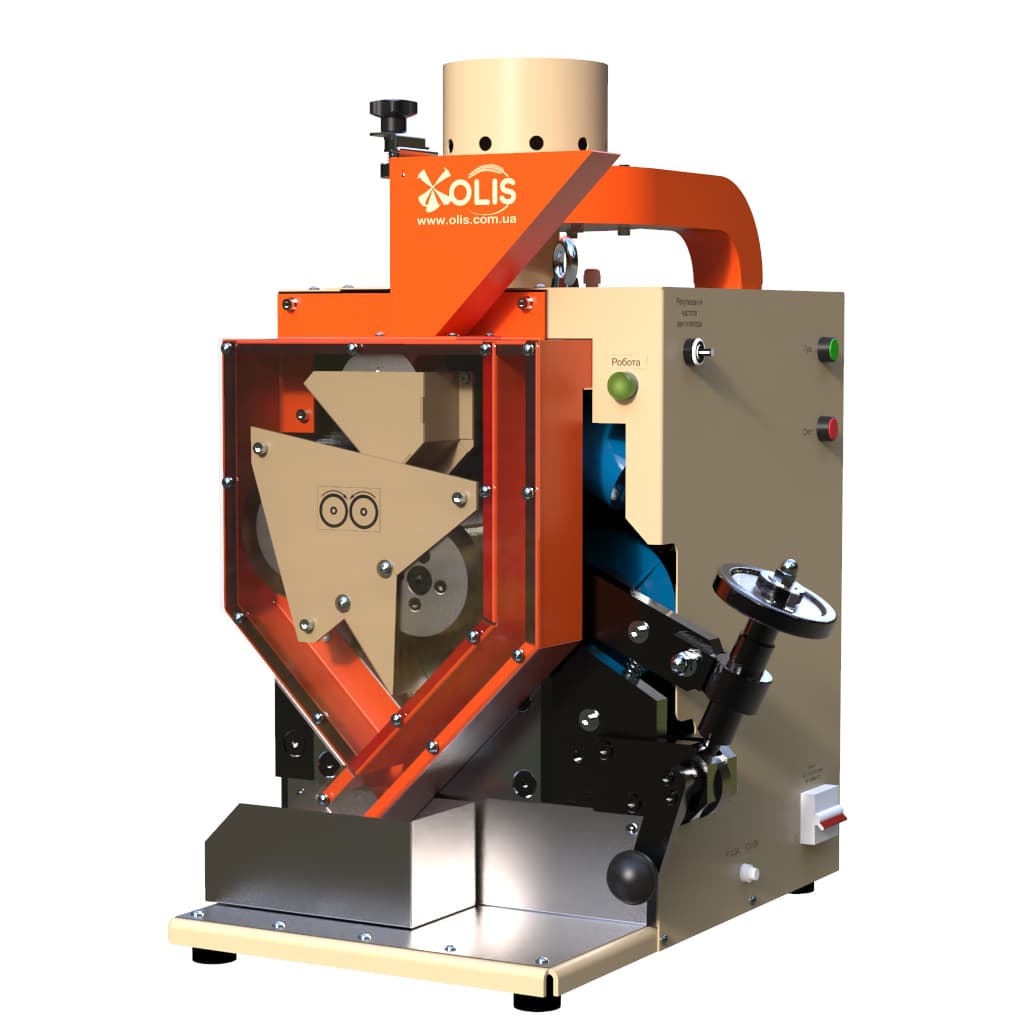

Laboratory Mill OLISLAB 2200

Purpose and scope:

Laboratory mill OlisLab 2200, a modernized version of the LMT-2 mill, hammer type, cyclone principle of operation, designed for grinding grains, legumes and oilseeds and their products in order to prepare samples for further analysis, which require grinding to a given fineness. namely: when determining the quantity and quality of gluten, Falling Number, protein content, as well as other indicators of product quality, including on the NIR analyzer.

With the help of the mill, the process of grinding a solid product with brittle or brittle-plastic properties is realized, due to impact deformation and abrasion, which is provided by the working body in the form of the impeller rotating at high speed.

It is used in grain receiving and grain processing enterprises, feed mills, oil extraction, bakery and other food enterprises, variety testing breeding stations, research laboratories and inspection companies.

Scope of application: for grinding a sample with a standardized determination in grain: gluten according to GOST 13586.1-68 (canceled in Ukraine); ISO 21415-1; ISO 21415-2; FN according to ISO 3093:2009; protein content according to ISO 20483:2013; as well as for use in other methods according to domestic and international standards.

Description:

The laboratory mill consists of the body on which the plate with the cyclone is mounted, the electric motor with the impeller, the receiving funnel, the table with a container for the ground product.

The principle of operation of the laboratory mill is based on grinding the product with the help of steel impeller blades rotating at high speed. When the impeller rotates, its blades act like the blades of a fan wheel, which creates a directed airflow. The initial product coming from the receiving funnel is picked up by the air flow and enters the shell of the plate with the impeller through a groove with a hole in the lid. When moving along the surface of the shell with a notch, the product is crushed, and its particles, together with air, pass through the sieve and are forced into the cyclone. After separation from the product, the air is forced out through the shell of the cover into the cavity of the plate, where it passes through the filters for cleaning and is thrown out. The crushed and separated from the air product enters the receiving container to collect the crushed product. The fineness of grinding is regulated by the size of the openings of the calibration sieve.

Specifications

| Model | OLISLAB 2200 |

| Type | hammer |

| Loading hopper volume, cm3 | 280 |

| Receiving hopper volume, cm3 | 250 |

| Sample weight (for wheat), g | 10…100 |

| Moisture content of grinding product, %, not more | 20 |

| Maximum size of crushed grains, mm, not moreе | 14 |

| Working body spindle speed, vib/min | 10200 |

| Operating mode: number of grindings per hour, pcs, not more | 30 |

| Sieve opening diameter, mm | 0,8; 1,0 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply: voltage / frequency, V / Hz | 230±23 / 50 |

| Power consumption, W | 550 |

| Overall dimensions L × W × H, | |

| – in working condition, mm, not more | 345 × 180 × 410 |

| – in transport condition, mm, not more | 370 × 190 × 450 |

| Net weight / gross weight, kg | 15,8 / 17,0 |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – relative humidity, % | 60 ± 15 |

Аdvantages

ERGONOMICS

Speed and convenience of loading and unloading products.

ACCURACY

The presence of self-cleaning devices for the dosing system, grinding chamber and product pipeline eliminates the mixing of the ground sample with the remnants of the previous sample.

Grinding of high uniformity.

VERSATILITY

It can be used for grinding grain of any grain and leguminous crop with high moisture content (up to 20%) due to the use of steel blades in the impeller and the presence of an adjustable automatic dosage of the product.

Adjustment of fineness of a grinding due to quick change of a calibration sieve.

SAFETY AND DURABILITY

The use of the air filter allows you to get rid of fine dust in the air that occurs when grinding grain.

The drive belt is multi-layered, reinforced – it is practically not removed and does not require regular tension.

Photo

| Model | OLISLAB 2200 |

| Type | hammer |

| Loading hopper volume, cm3 | 280 |

| Receiving hopper volume, cm3 | 250 |

| Sample weight (for wheat), g | 10…100 |

| Moisture content of grinding product, %, not more | 20 |

| Maximum size of crushed grains, mm, not moreе | 14 |

| Working body spindle speed, vib/min | 10200 |

| Operating mode: number of grindings per hour, pcs, not more | 30 |

| Sieve opening diameter, mm | 0,8; 1,0 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply: voltage / frequency, V / Hz | 230±23 / 50 |

| Power consumption, W | 550 |

| Overall dimensions L × W × H, | |

| – in working condition, mm, not more | 345 × 180 × 410 |

| – in transport condition, mm, not more | 370 × 190 × 450 |

| Net weight / gross weight, kg | 15,8 / 17,0 |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – relative humidity, % | 60 ± 15 |

ERGONOMICS

Speed and convenience of loading and unloading products.

ACCURACY

The presence of self-cleaning devices for the dosing system, grinding chamber and product pipeline eliminates the mixing of the ground sample with the remnants of the previous sample.

Grinding of high uniformity.

VERSATILITY

It can be used for grinding grain of any grain and leguminous crop with high moisture content (up to 20%) due to the use of steel blades in the impeller and the presence of an adjustable automatic dosage of the product.

Adjustment of fineness of a grinding due to quick change of a calibration sieve.

SAFETY AND DURABILITY

The use of the air filter allows you to get rid of fine dust in the air that occurs when grinding grain.

The drive belt is multi-layered, reinforced – it is practically not removed and does not require regular tension.