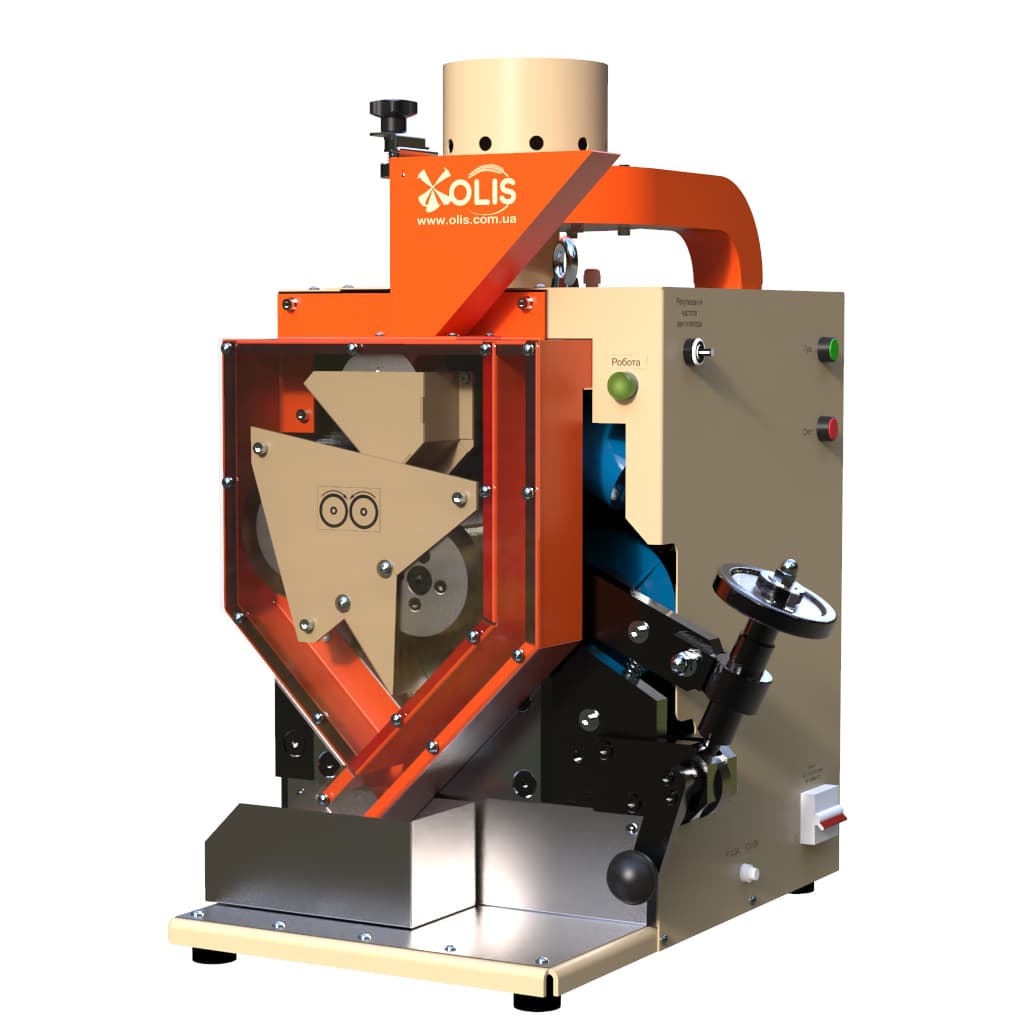

Laboratory Huller & Polisher OLISLAB 3100

Purpose and scope:

Laboratory huller & polisher OlisLab 3100 (universal), a modernized version of the UShZ-1 huller, abrasive type, designed to study the processes of hulling, grinding, evaluating groats properties and grain hardness.

With the help of the device, the process of grain peeling is realized according to the principle of intensive abrasion of its surface against the abrasive surface of the grinding wheel, with the formation of hulling products in the form of flour, as well as the process of grinding (polishing) the peeled core.

It is used in grain processing enterprises, feed mills, variety testing breeding stations and research laboratories.

Scope of application: for the standardized determination of cereal properties of grain according to DSTU ISO 6646:2003 / ISO 6646:2000 / “Fig. Determining the potential amount of milling from paddy and husked rice”; ISO 6646:2011 “Rice – Determination of the potential milling yield from paddy and from husked rice”; as well as for use in other methods according to domestic and international standards.

Description:

The device consists of a huller, in which grinding wheels are installed, and an electric motor, which are placed on the plate. The front panel contains an indicator board and control buttons.

With the help of the device, the process of grain peeling is realized according to the principle of intensive abrasion of its surface against the abrasive surface of the grinding wheel, with the formation of hulling products in the form of flour, as well as the process of grinding (polishing) the peeled core.

Ideal for surface treatment of grains and assessment of the hulling index of such grains and legumes as: barley, wheat, corn, peas, chickpeas, lentils. It can be used to assess the large properties of sorghum, sorghum oryzoidum.

Principle of operation: the initial product from the loading hopper enters the working chamber, in which it interacts with rotating grinding wheels and a sieve. Due to the intense friction of the grain, both on the surface of the grinding wheels and on the surface of the sieve, the shells are separated from the grain and abraded into small particles. Small particles of shells pass through the sieve shell, with an opening diameter of 2.0 mm, and fall into collection containers for flour. After the set hulling/grinding time has elapsed and the grinding wheels have stopped, the gate valve is opened by the user and the processed product (hulled grain) enters the collection container for the main product.

For effective operation of the huller, it is necessary to select the dimensions (width) of the grinding wheels (2×20; 1×32, 1×20); kinematic parameters (mode 1 or 2); the weight of the product and the duration of treatment, depending on the type of grain and the desired degree of processing of its surface.

Specifications

| Model | OLISLAB 3100 |

| Type | abrasive |

| Receiving hopper volume, cm3 | 200 |

| Humidity of hulling products, %, not mor | 20 |

| Hulling duration setting range, min / sec | |

| Sieve opening diameter, mm | 2,0 |

| Number of kinematic modes of operation | 2 |

| Working body spindle speed, vib/min | 1500/2500 |

| Circumferential speed of the grinding wheel, m/sec | 9,6 / 1 |

| Noise level, dB, no more | 70 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply, V / Hz | 230±23 / 50 |

| Power consumption, W | 550 |

| Overall dimensions L × W × H, | |

| – in working condition, mm, not more | 525 × 375 × 485 |

| – in transportable condition, mm, not more | |

| Net / gross weight, kg | 25 / |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – relative humidity, % | 60 ± 15 |

Аdvantages

FUNCTIONALITY

Low yield of broken grains.

Fast removal of particles from the working zone.

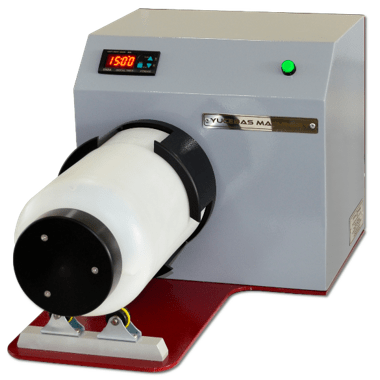

ERGONOMICS

Convenient adjustment of hulling duration.

The indicator panel with a countdown is clearly visible.

Sound alarm.

Fast and convenient replacement of grinding wheels if necessary.

COMPACT

Small dimensions and relatively low weight of the device do not require a special reinforced design of the desktop.

VERSATILITY

It can be used to assess the groats properties of such grains and legumes as: barley, wheat, corn, peas, chickpeas, lentils, sorghum, sorghum oryzoidum.

Can be used for:

– evaluation of groats properties of grain;

– determination of grain hardness by hulling index;

– setting up technological equipment and scientific substantiation of the structure and modes of processes: hulling, grinding, moisture-thermal treatment.

SAFETY AND DURABILITY

Device resource for the first medium repair is 10 thousand hours.

The service life of the device is 10 years.

Photos

| Model | OLISLAB 3100 |

| Type | abrasive |

| Receiving hopper volume, cm3 | 200 |

| Humidity of hulling products, %, not mor | 20 |

| Hulling duration setting range, min / sec | |

| Sieve opening diameter, mm | 2,0 |

| Number of kinematic modes of operation | 2 |

| Working body spindle speed, vib/min | 1500/2500 |

| Circumferential speed of the grinding wheel, m/sec | 9,6 / 1 |

| Noise level, dB, no more | 70 |

| Protection class against electric shock | I |

| Network type | 1N~ |

| Power supply, V / Hz | 230±23 / 50 |

| Power consumption, W | 550 |

| Overall dimensions L × W × H, | |

| – in working condition, mm, not more | 525 × 375 × 485 |

| – in transportable condition, mm, not more | |

| Net / gross weight, kg | 25 / |

| Operating conditions: | |

| – ambient temperature, ℃ | 5…30 |

| – relative humidity, % | 60 ± 15 |

FUNCTIONALITY

Low yield of broken grains.

Fast removal of particles from the working zone.

ERGONOMICS

Convenient adjustment of hulling duration.

The indicator panel with a countdown is clearly visible.

Sound alarm.

Fast and convenient replacement of grinding wheels if necessary.

COMPACT

Small dimensions and relatively low weight of the device do not require a special reinforced design of the desktop.

VERSATILITY

It can be used to assess the groats properties of such grains and legumes as: barley, wheat, corn, peas, chickpeas, lentils, sorghum, sorghum oryzoidum.

Can be used for:

– evaluation of groats properties of grain;

– determination of grain hardness by hulling index;

– setting up technological equipment and scientific substantiation of the structure and modes of processes: hulling, grinding, moisture-thermal treatment.

SAFETY AND DURABILITY

Device resource for the first medium repair is 10 thousand hours.

The service life of the device is 10 years.