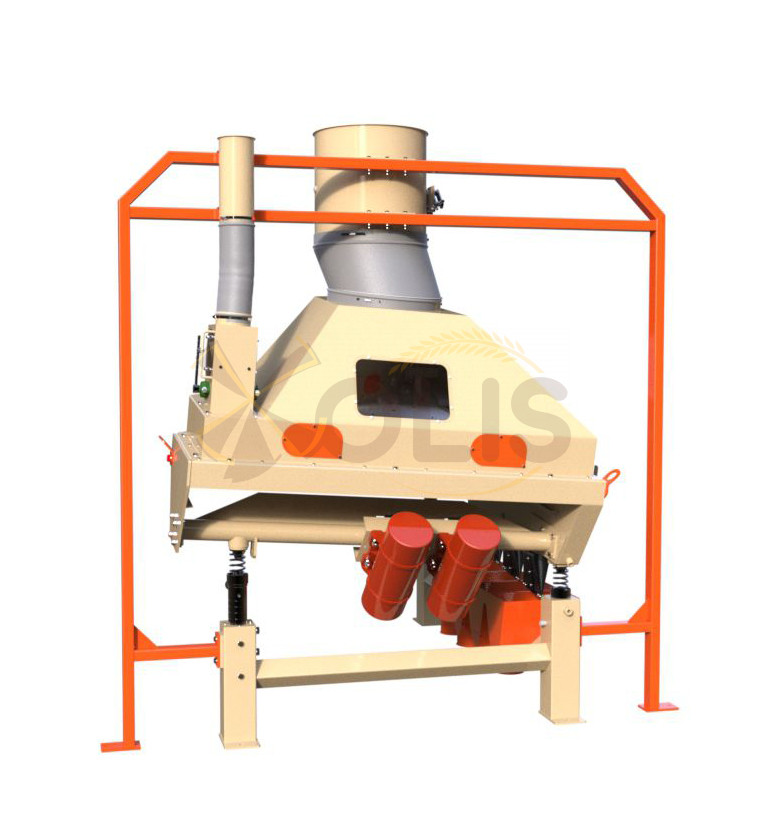

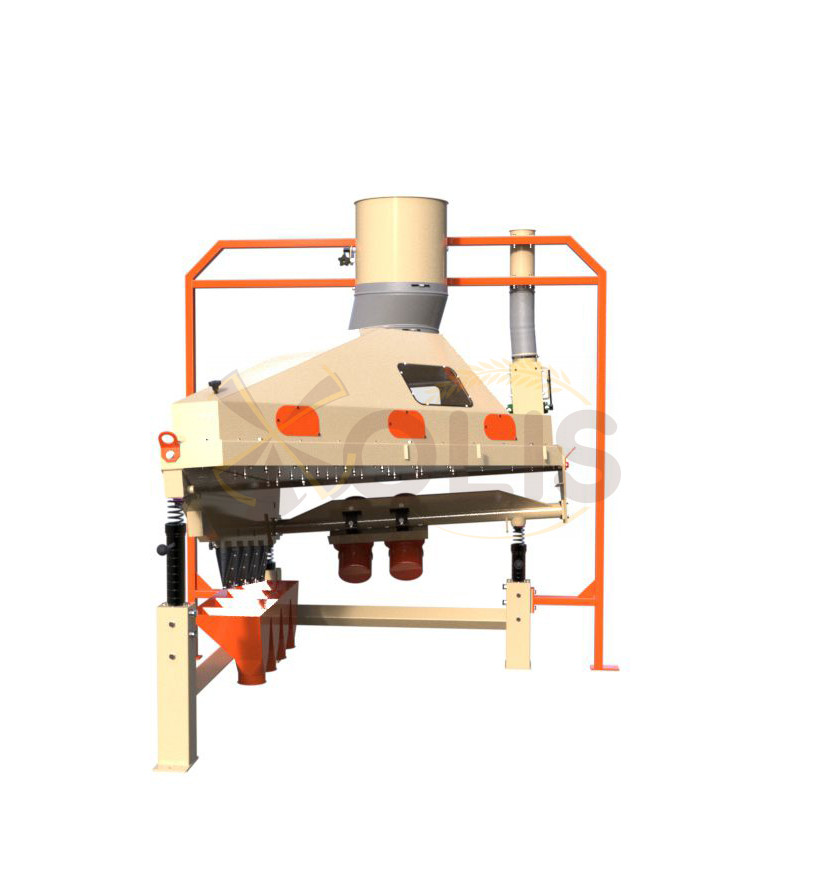

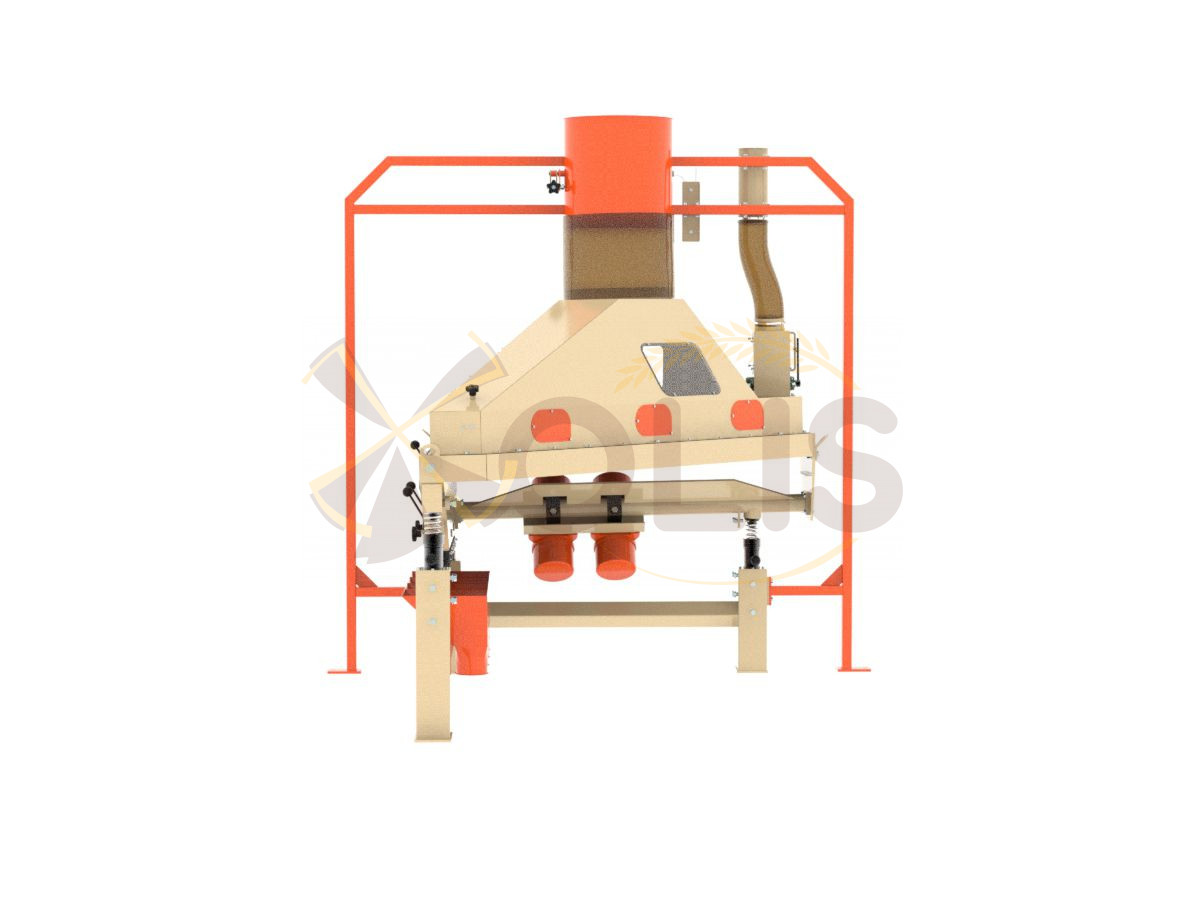

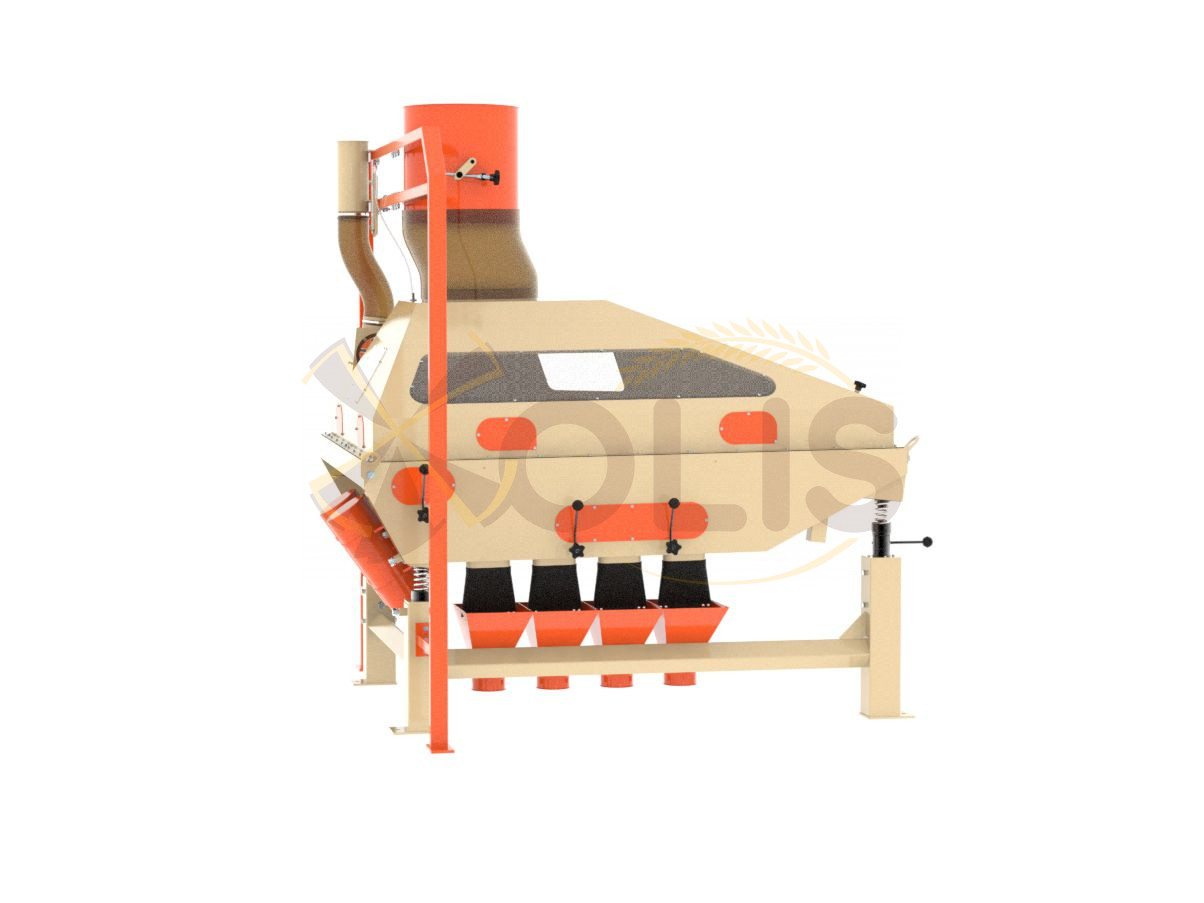

Gravity Separator SPS-3.5

Purpose:

Gravity separator SPS-3.5, manufactured by “OLIS” Ltd, is used for cleaning the seeds of grain legumes crops, grain crops, oilseeds crops and groats crops from hard-separable impurities which differ from the main grain in shape, surface properties, and volume weight. The gravity separator can also be used for selection of mineral impurities.

Description:

On the vibro-pneumatic table, grain mass is divided into fractions depending on shape, volume weight and surface properties, ensuring the selection of fine, shrunken, broken and damaged by pests and some microorganisms’ grain from grain mass, which allows to obtain from one to four fractions equal in size and density. As a result which SPS-3.5 has a wide technological application, it can be installed at the stage of grain cleaning from various impurities, its calibration, including selecting the best quality seed material. It can be also installed in lines of groats production for hulled grain separation or forming finished products to sort groats into grades and numbers. It is used for groats enrichment units UOK-1 and UOK-2 manufactured by OLIS Ltd.

Grain processing:

Before feeding the grain to the machine, it is necessary to clean the grain mass on a sieve-air separator and indented cylinder separator and ensure the moisture content corresponding to this product.

The product enters the working area of the machine through the loading pipe, thanks to a special valve it is evenly distributed along the inclined plane of the deck. The valve eliminates the possibility of suction of air through the loading nozzle into the machine working area. The body of the pneumatic sorting table is sheathed with the special metal mesh and performs longitudinal oscillatory motion. Steadiness of air flow is ensured by the provided distribution device.

With uniform vibration of the working plane, air intake through the pipe with the throttle valve and lateral, as well as transverse inclination, high-quality sorting of the product is carried out. All coarse products remain on the deck grid and under the influence of lateral oscillations is sent through the pipe to the outlet. Light particles are proceeded to the lateral sides of the deck and are discharged through the pipe.

The coarse fraction goes in the opposite direction – in the direction of the horizontal valve of the deck with the hole. This valve allows creating countercurrent circulation of adjustable speed air flow. Thus, the product can be separated in fractures, which differ in weight, which are proceeded into the bottom container. Air used in separation may contain light product fractions or dust and, thus, is thoroughly cleaned in a filter or a cyclone.

Specifications

| Model | SPS-3,5 |

| Productivity (of wheat), t/h | 3,5 |

| Pre-installed electric power capacity, kW | 1,1 |

| Table oscillation frequency, c-1 (oscillations/min) | 15,6 (940) |

| Table oscillation amplitude, mm | 5-6 |

| Angle of inclination of the deck (of the table), ° lateral transverse |

0-8 0-8 |

| Degree of impurity separation, % | 75-90 |

| Main grain content in the impurities, % | 5-15 |

| Required air flow, m3/min, (m3/h), no more | 140(8400) |

| Weight, kg | 540 |

| Overall dimensions, mm length width height |

2149 1937 2341 |

Аdvantages

- High accuracy of adjustment of sorting parameters, which allows to achieve optimal modes;

- A special viewing glass is installed, which allows you to conveniently observe the adjustment process;

- High strength construction;

- Use of components from leading European manufacturers;

- Use of a deck of a special design, which significantly increases the quality of sorting.

Videos

Photos

| Model | SPS-3,5 |

| Productivity (of wheat), t/h | 3,5 |

| Pre-installed electric power capacity, kW | 1,1 |

| Table oscillation frequency, c-1 (oscillations/min) | 15,6 (940) |

| Table oscillation amplitude, mm | 5-6 |

| Angle of inclination of the deck (of the table), ° lateral transverse |

0-8 0-8 |

| Degree of impurity separation, % | 75-90 |

| Main grain content in the impurities, % | 5-15 |

| Required air flow, m3/min, (m3/h), no more | 140(8400) |

| Weight, kg | 540 |

| Overall dimensions, mm length width height |

2149 1937 2341 |

- High accuracy of adjustment of sorting parameters, which allows to achieve optimal modes;

- A special viewing glass is installed, which allows you to conveniently observe the adjustment process;

- High strength construction;

- Use of components from leading European manufacturers;

- Use of a deck of a special design, which significantly increases the quality of sorting.