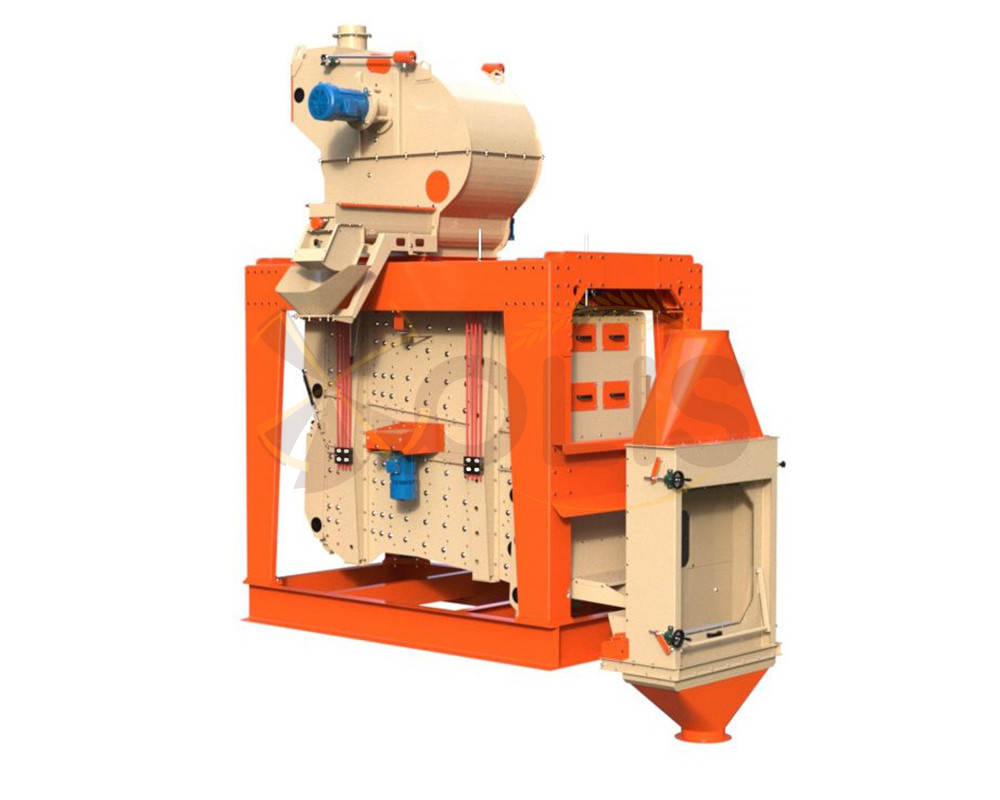

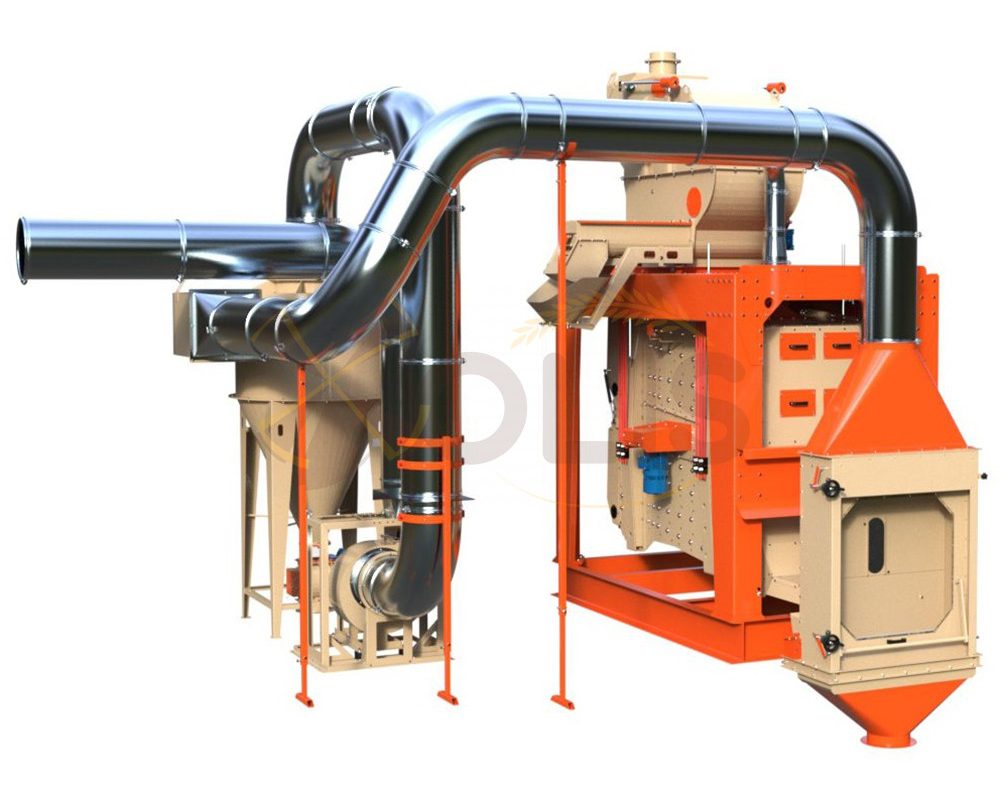

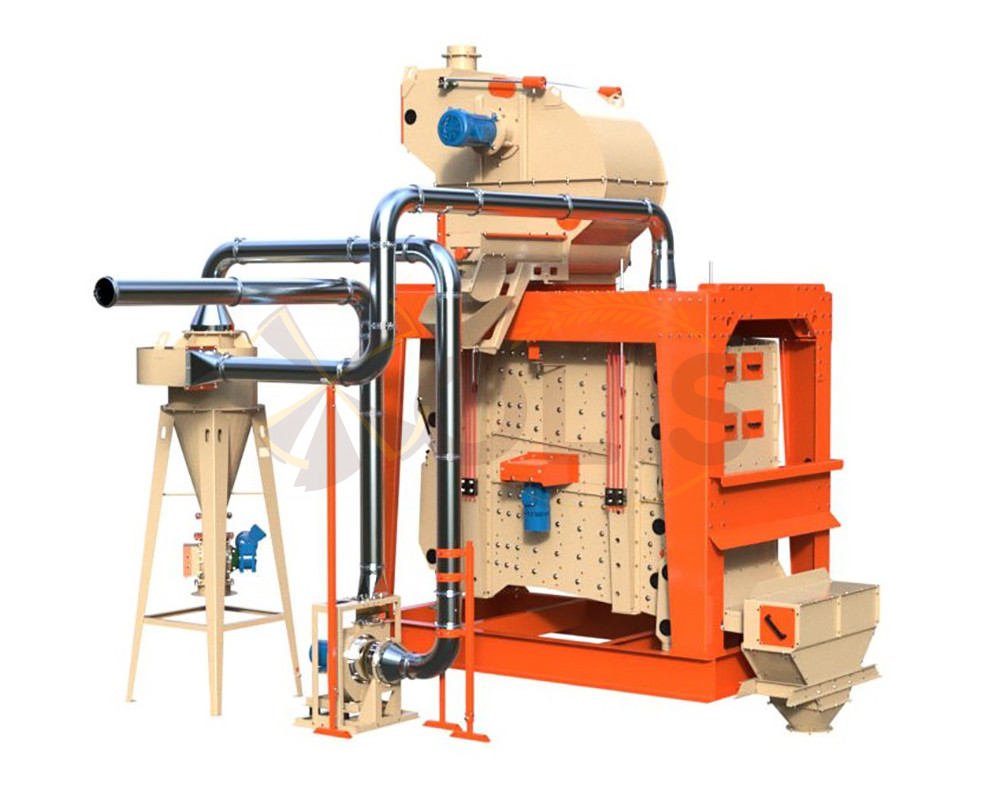

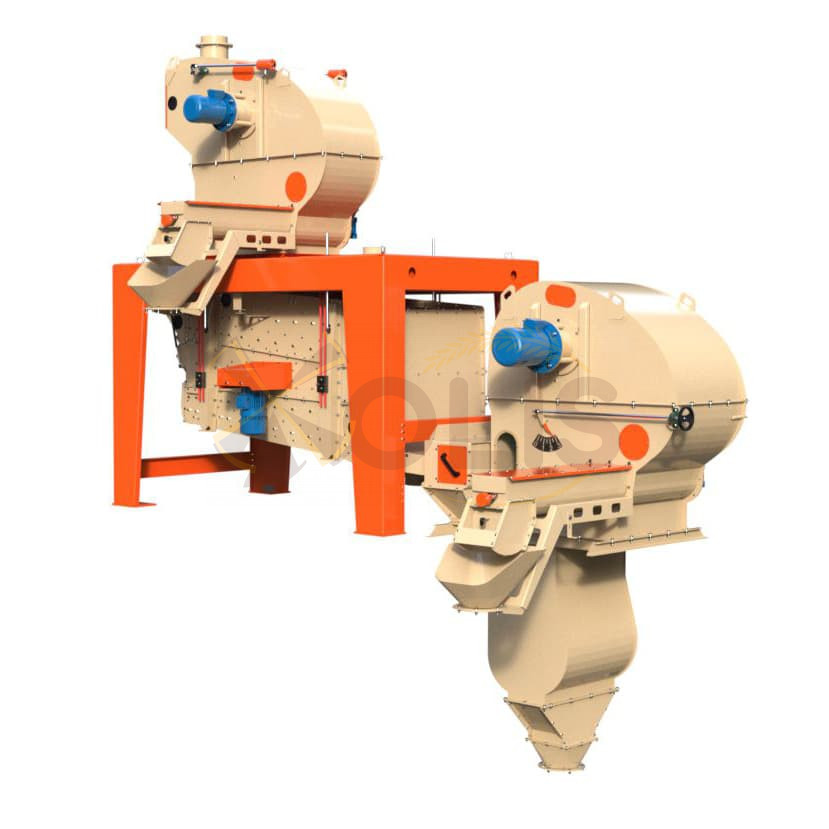

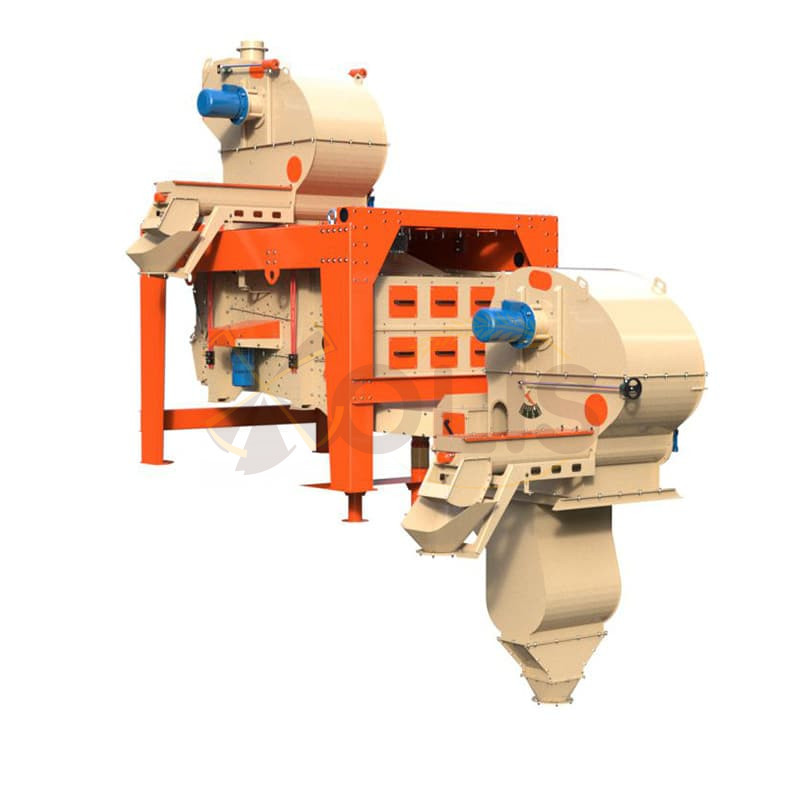

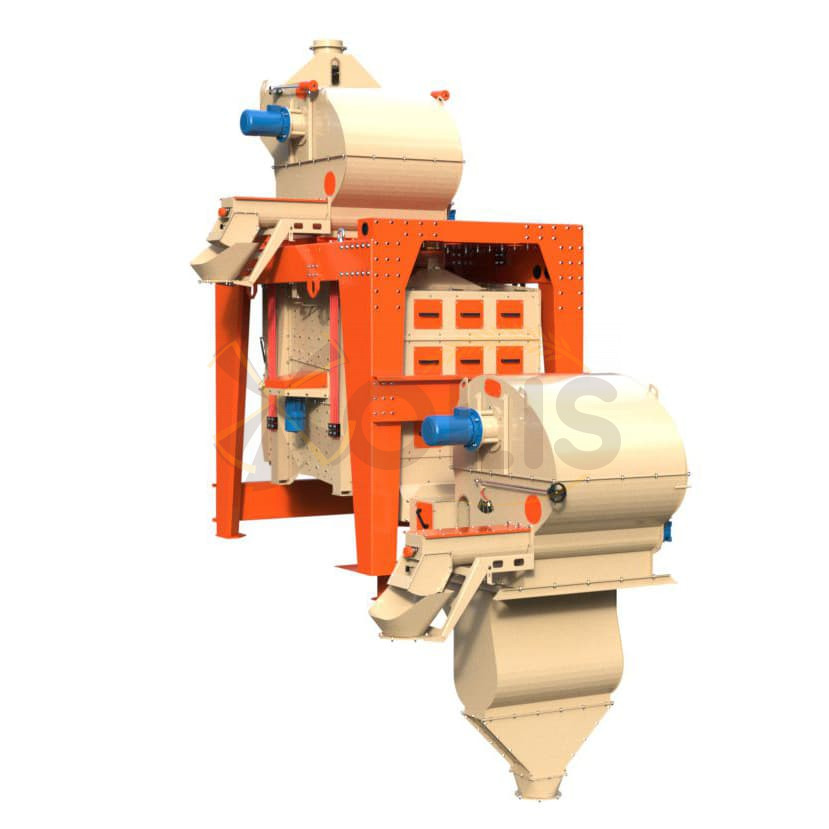

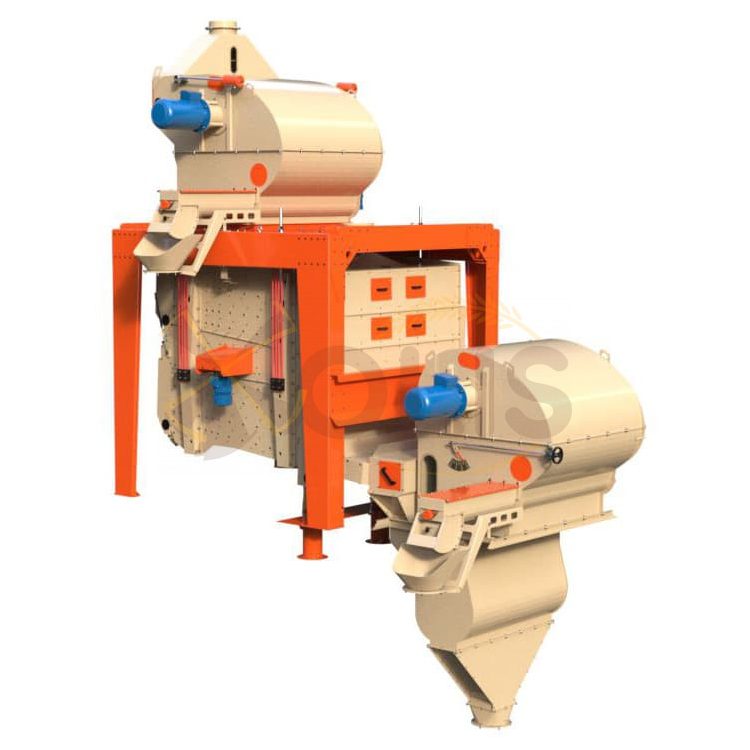

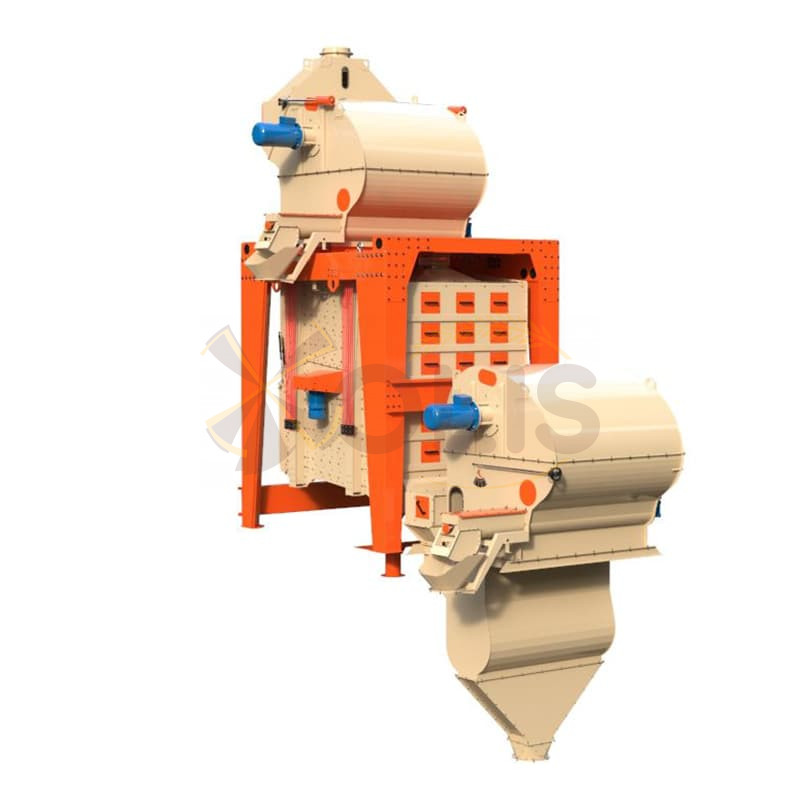

Screen Cleaner HORIZONT-К-250

Application:

Screen cleaner “HORIZONT-K-250” is designed for grain cleaning from coarse, fine and light impurities in grain elevators, mills and other grain processing facilities. The separator ensures the following operations: preliminary cleaning, primary cleaning, secondary cleaning (sorting, calibration).

The screen cleaner “HORIZONT-K-130” can be equipped with an air separator with a closed air cycle VSZ-80, an air separator with a closed air cycle VSZM-80, as well as an aspiration column KAO-1.3.

Principle of operation:

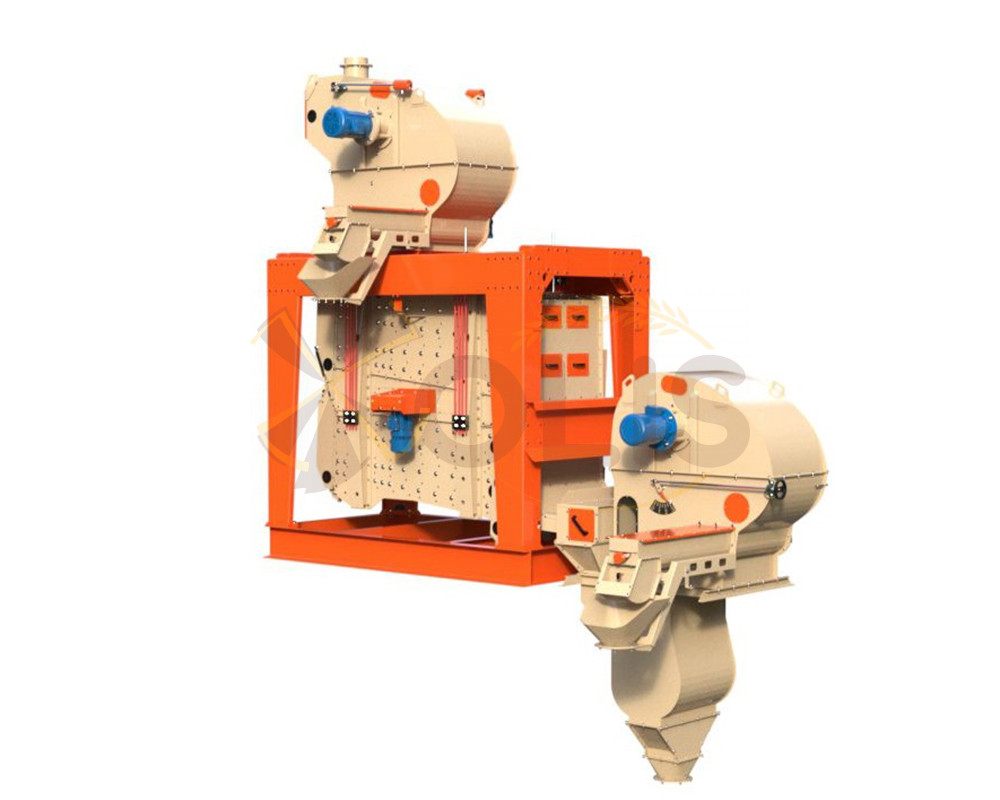

Composition: sieve flat-grid separator Horizont-K-250, air separator with a closed air cycle VSZ-80, air separator with a closed air cycle VSZM-80, control panel.

Description: The cleaned grain after the flat-sieve separator can be additionally directed to the air separator with a closed air cycle VSZM-80 for additional selection of light impurities.

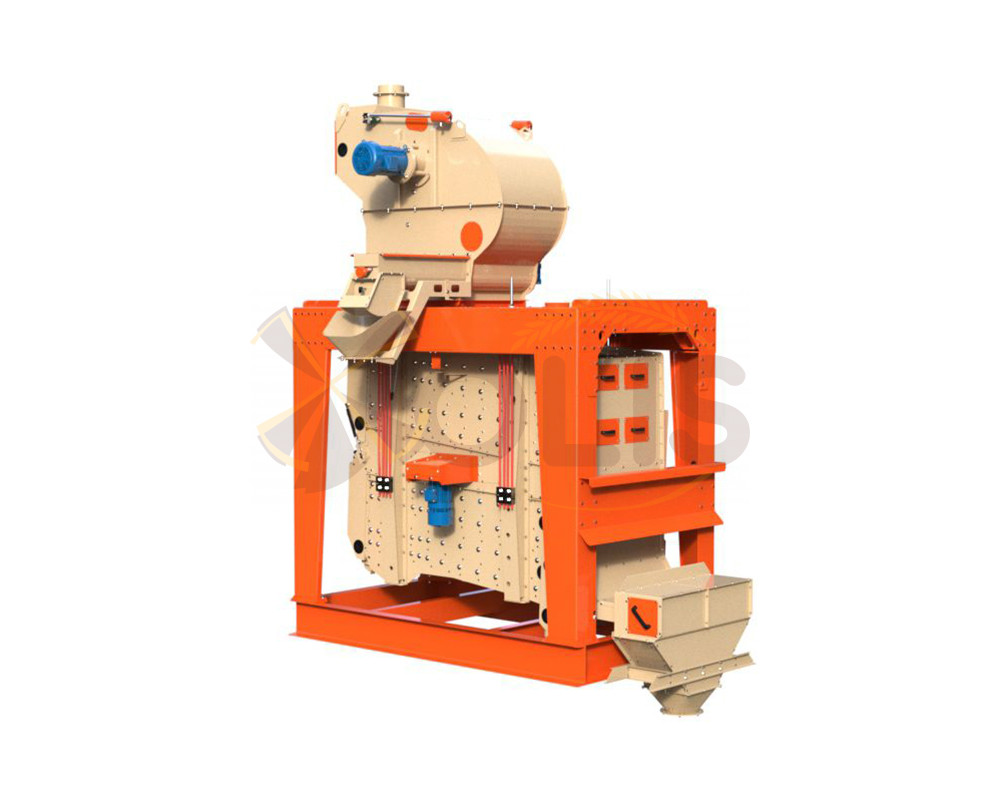

Composition: sieve flat-grid separator Horizont-K-250, air separator with a closed air cycle VSZ-80, aspiration column КАО-1.3, control panel.

Description: The cleaned grain after the flat-sieve separator can be additionally directed to the aspiration column KAO-1.3 for additional selection of light impurities.

Composition: sieve flat-grid separator Horizont-K-250, air separator with a closed air cycle VSZ-80, funnel, control panel.

Description: The initial grain enters the air separator with a closed air cycle VSZ-80 for light impurities separation, after which it enters the flat-sieve separator, where the grain is cleaned of impurities which differ in geometric dimensions. The obtained fractions of purified grain and impurities are separately removed from the machine through outlet nozzles.

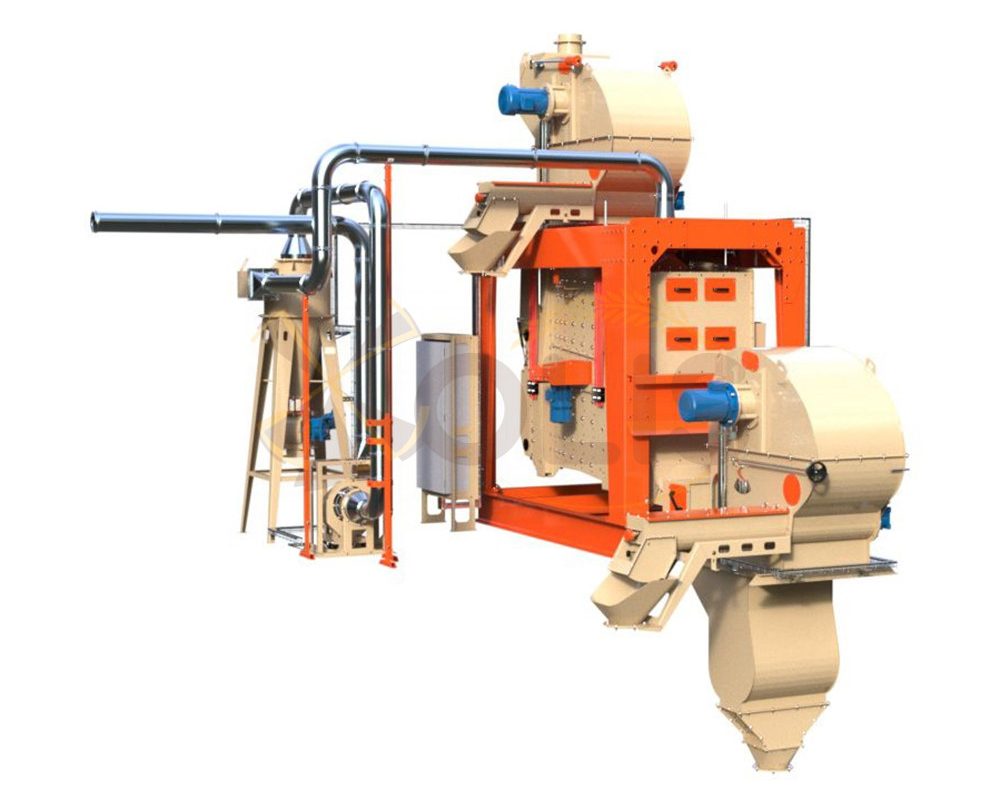

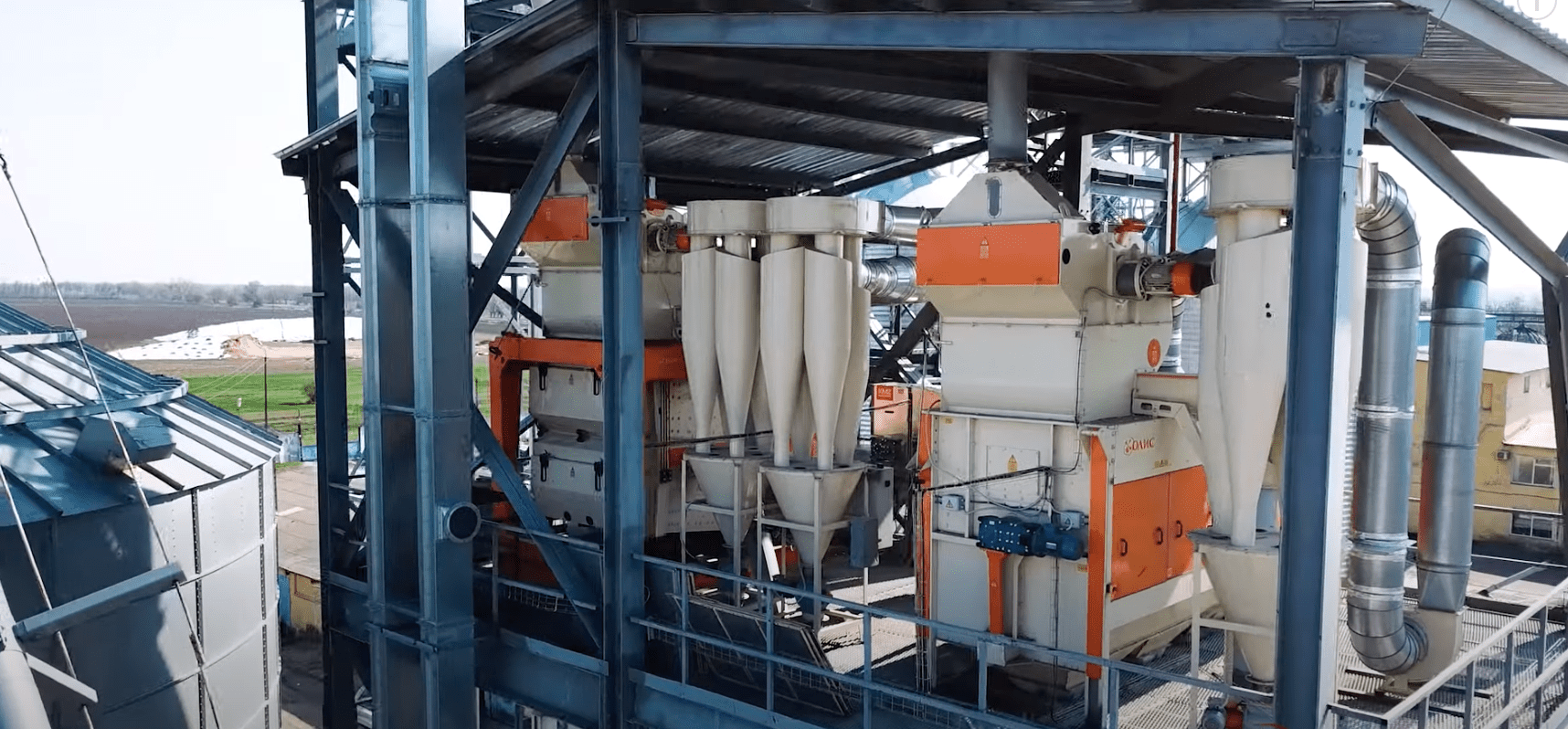

To simplify installation work and ensure the most efficient operation of the flat-grid type separator, the company OLIS has developed an aggregated solution Horizont-К-250А.

Aggregate screen cleaner Horizont-К-250А includes 3 variants of complete sets:

Modification 01 – sieve flat-grid separator Horizont-K-250, air separator with a closed air cycle VSZ-80, air separator with a closed air cycle VSZM-80, cyclone with sluice gate and drive, fan, air ducts, control panel, cables, trays and ladders.

Modification 02 – sieve flat-grid separator Horizont-K-250, air separator with a closed air cycle VSZ-80, aspiration column KAO-1.3, cyclone with sluice gate and drive, fan, air ducts, control panel, cables, trays and ladders.

Modification 06 – sieve flat-grid separator Horizont-K-250, air separator with a closed air cycle VSZ-80, funnel, cyclone with sluice gate and drive, fan, air ducts, control panel, cables, trays and ladders.

Specifications

| Model | HORIZONT-К-250 | HORIZONT-К-250А |

| Productivity, up to t/h: Primary cleaning (of wheat) |

80 | 80 |

| Working surface of sieves, m2 | 16 | 16 |

| Modification 01 | VSZ-80 + VSZM-80 | VSZ-80 + VSZM-80 + АС + ЭС |

| Air consumption for aspiration, m3/h | 1000 | 1000 |

| Pre-installed electric power capacity, kW | 15,40 | 19,15 |

| Weight, kg | 6791 | 7272 |

| Overall dimensions of the separator, mm: length width height |

5305 2875 4680 |

5305 6140 4680 |

| Modification 02 | VSZ-80 + КАО-1.3 | VSZ-80 + КАО-1,3 + АС + ЭС |

| Air consumption for aspiration, m3/h | 7300 | 7300 |

| Pre-installed electric power capacity, kW | 8,80 | 17,05 |

| Weight, kg | 6114 | 7001 |

| Overall dimensions of the separator, mm: length width height |

3995 2630 4680 |

3995 6450 4680 |

| Modification 06 | VSZ-80 + PKPSO-130 | VSZ-80 + PKPSO-130 + АС + ЭС |

| Air consumption for aspiration, m3/h | 1000 | 1000 |

| Pre-installed electric power capacity, kW | 8,80 | 12,55 |

| Weight, kg | 5961 | 6424 |

| Overall dimensions of the separator, mm: length width height |

3650 2630 4680 |

3650 6140 4680 |

А * – с применением аспирации, кабельных лотков, шкафа управления.

Аdvantages

- High productivity with a small area occupied by the separator;

- Effective grain cleaning due to large area of operating surface of sieves;

- Design reliability and ease of use;

- Use of simple, reliable and highly effective means of cleaning sieves;

- Possibility of organizing a double air separation of grain (at the entrance to the sieve body and at the exit from it) with the additional installation of an air separator VSN or an air separator VSZ;

- Low power consumption.

Videos

Photos

| Model | HORIZONT-К-250 | HORIZONT-К-250А |

| Productivity, up to t/h: Primary cleaning (of wheat) |

80 | 80 |

| Working surface of sieves, m2 | 16 | 16 |

| Modification 01 | VSZ-80 + VSZM-80 | VSZ-80 + VSZM-80 + АС + ЭС |

| Air consumption for aspiration, m3/h | 1000 | 1000 |

| Pre-installed electric power capacity, kW | 15,40 | 19,15 |

| Weight, kg | 6791 | 7272 |

| Overall dimensions of the separator, mm: length width height |

5305 2875 4680 |

5305 6140 4680 |

| Modification 02 | VSZ-80 + КАО-1.3 | VSZ-80 + КАО-1,3 + АС + ЭС |

| Air consumption for aspiration, m3/h | 7300 | 7300 |

| Pre-installed electric power capacity, kW | 8,80 | 17,05 |

| Weight, kg | 6114 | 7001 |

| Overall dimensions of the separator, mm: length width height |

3995 2630 4680 |

3995 6450 4680 |

| Modification 06 | VSZ-80 + PKPSO-130 | VSZ-80 + PKPSO-130 + АС + ЭС |

| Air consumption for aspiration, m3/h | 1000 | 1000 |

| Pre-installed electric power capacity, kW | 8,80 | 12,55 |

| Weight, kg | 5961 | 6424 |

| Overall dimensions of the separator, mm: length width height |

3650 2630 4680 |

3650 6140 4680 |

А * – с применением аспирации, кабельных лотков, шкафа управления.

- High productivity with a small area occupied by the separator;

- Effective grain cleaning due to large area of operating surface of sieves;

- Design reliability and ease of use;

- Use of simple, reliable and highly effective means of cleaning sieves;

- Possibility of organizing a double air separation of grain (at the entrance to the sieve body and at the exit from it) with the additional installation of an air separator VSN or an air separator VSZ;

- Low power consumption.