Scourers MBO-3, MBO-6; MAO-3, MAO-6

Purpose and scope of application: Scourers MBO and MAO are designed for grain surface cleaning from mineral impurities, partial removal of grain hairs, germ and cracked hulls of grain. They are used in grain cleaning units of mills for grain preparation for grinding.

Description: Scourer consist of the frame, the drive and the body in which can be mounted the rotor with whips and the sieve frame (MBO-3/6), the rotor with abrasive disks and the sieve frame (MAO-3/6). Listed operating objects are interchangeable, so it allows depending on machine installation in the cleaning scheme for each grain batch to pick up the most efficient complete set. Grain enters the scourer through the inlet pipe and processed as a result of interaction with the movable objects and due to the friction between them. Cleaned grain is discharged through the outlet pipe and wastes are removed through the bottom of the funnel for dust.

Specifications

| Model | MBO-3 | MBO-6 | МАО-3 | МАО-6 |

| Productivity, kg/h | 3000 | 6000 | 3000 | 6000 |

| Decreased ash content of grain, % | 0,02-0,03 | 0,02-0,03 | 0,03-0,05 | 0,03-0,05 |

| Air consumption for aspiration, m3/h | 100 | 300 | 100 | 300 |

| Pre-installed electric power capacity, kW | 3,000 | 11,00 | 5,50 | 11,00 |

| Weight, kg | 275 | 630 | 315 | 670 |

| Overall dimensions, mm length width height |

1100 400 1300 |

1400 510 1620 |

1100 400 1300 |

1400 510 1620 |

Аdvantages

- Metal-intensive, durable construction;

- High efficiency and reliability (a wear-resistant coating is applied to the working bodies);

- Low specific power consumption;

- Small dimensions;

- Ease of operation and maintenance;

- The machine can be installed: the rotor with whips and the sieve frame (MBO-3/6) or the rotor with abrasive discs and the sieve frame (MAO-3/6);

- The rotor can be quickly changed as they are interchangeable.

- Components from leading European manufacturers are used;

- The bearings taken out outside protected from hit of dust and by it, considerably increasing an overhaul interval of the machine.

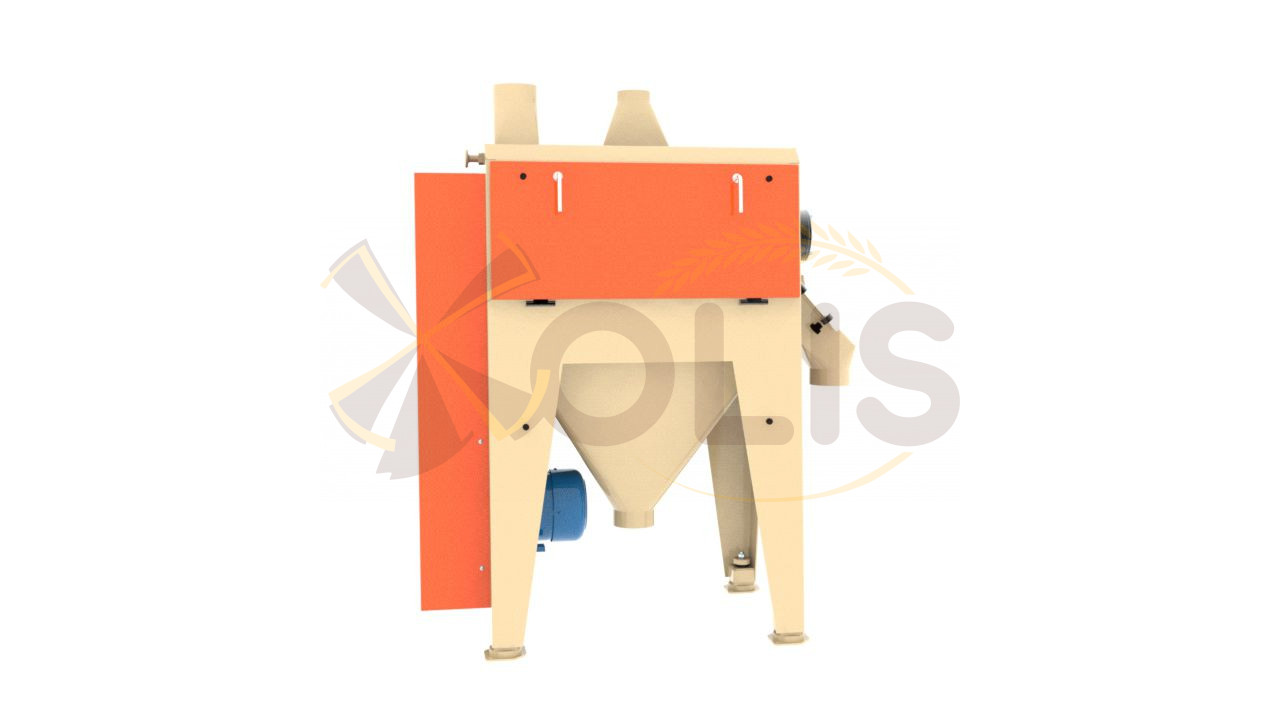

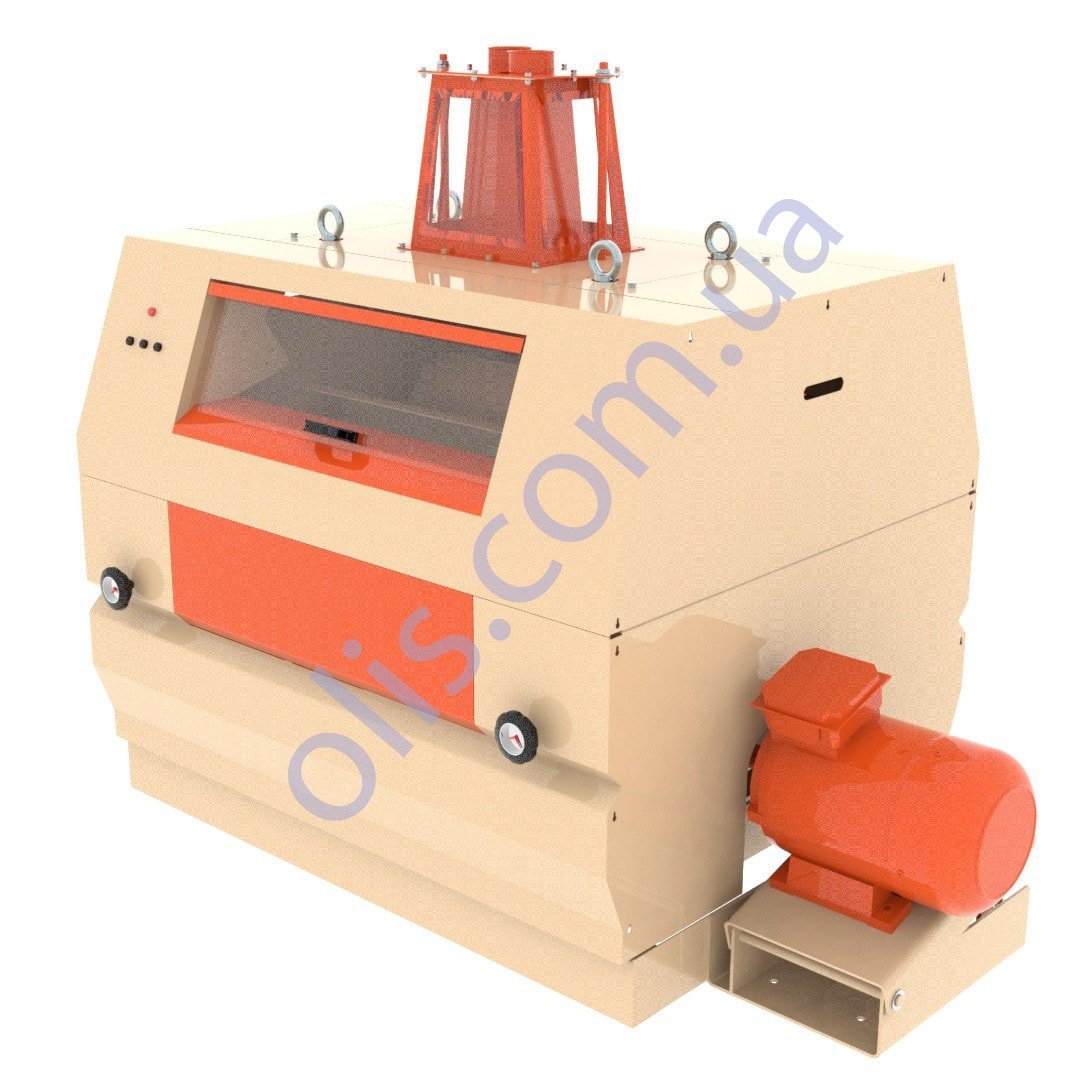

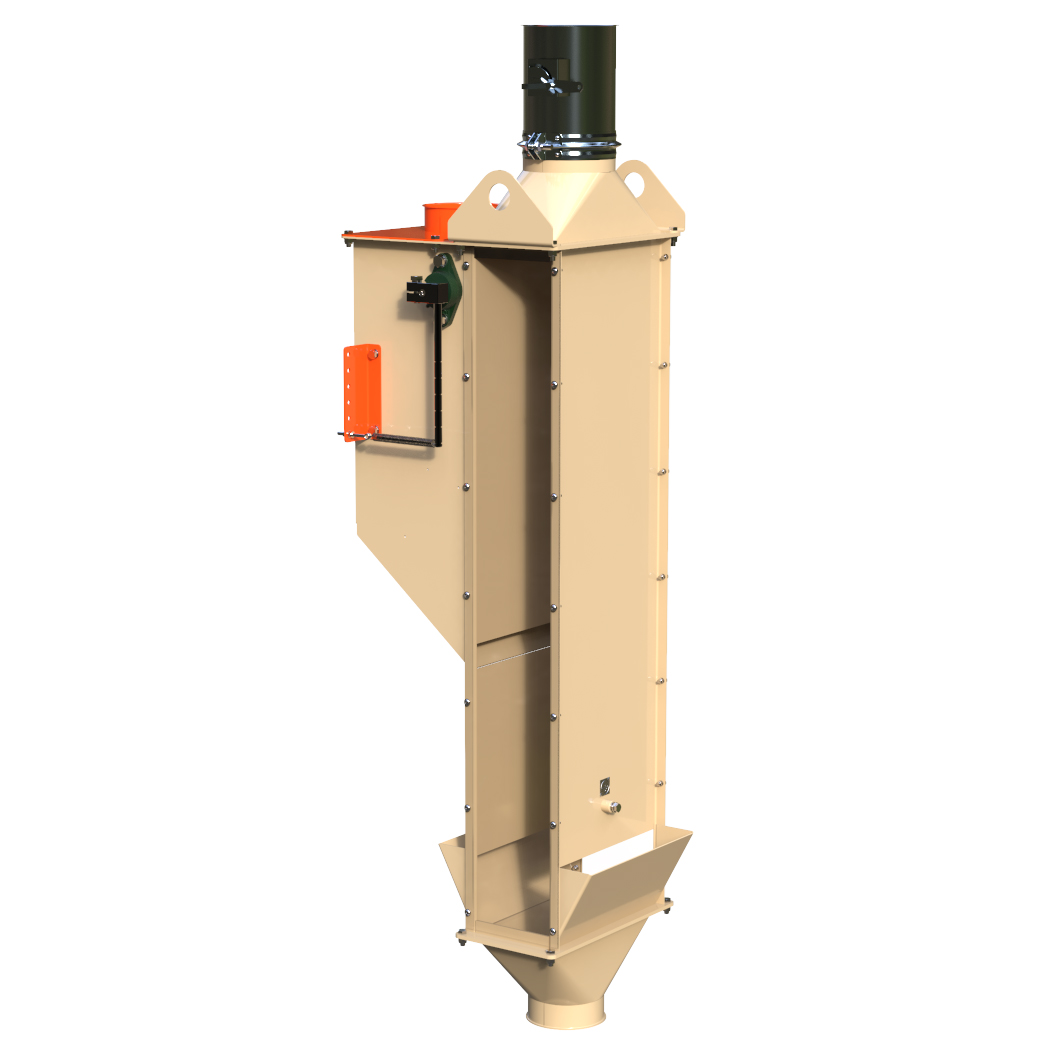

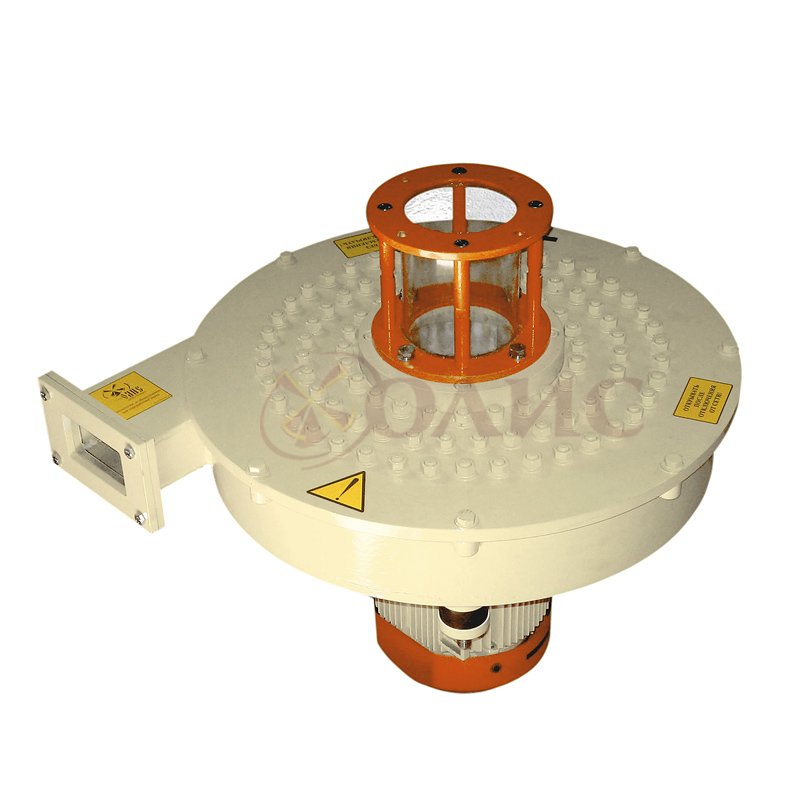

Photos

| Model | MBO-3 | MBO-6 | МАО-3 | МАО-6 |

| Productivity, kg/h | 3000 | 6000 | 3000 | 6000 |

| Decreased ash content of grain, % | 0,02-0,03 | 0,02-0,03 | 0,03-0,05 | 0,03-0,05 |

| Air consumption for aspiration, m3/h | 100 | 300 | 100 | 300 |

| Pre-installed electric power capacity, kW | 3,000 | 11,00 | 5,50 | 11,00 |

| Weight, kg | 275 | 630 | 315 | 670 |

| Overall dimensions, mm length width height |

1100 400 1300 |

1400 510 1620 |

1100 400 1300 |

1400 510 1620 |

- Metal-intensive, durable construction;

- High efficiency and reliability (a wear-resistant coating is applied to the working bodies);

- Low specific power consumption;

- Small dimensions;

- Ease of operation and maintenance;

- The machine can be installed: the rotor with whips and the sieve frame (MBO-3/6) or the rotor with abrasive discs and the sieve frame (MAO-3/6);

- The rotor can be quickly changed as they are interchangeable.

- Components from leading European manufacturers are used;

- The bearings taken out outside protected from hit of dust and by it, considerably increasing an overhaul interval of the machine.