Equipment for grain cleaning and processing should be easy to operate, reliable and efficient.

At first glance, the equipment for grain cleaning and processing is very simple. However, it is impossible to breathe life into it and achieve maximum reliability and efficiency without a professional understanding of grain processing technologies taking into account the peculiarities of each culture. Only in a combination of a scientific approach, design talent, a relentless desire for improvement and the ability to unite the best specialists can you create products that will be chosen by agricultural producers and processors. OLIS Ltd, which celebrated its 20th anniversary on April 8, is guided by these principles and virtues.

Testing is the key to reliability

Today, OLIS grain cleaning, processing and quality control equipment works in every corner of Ukraine and far beyond its borders.

Together with the Doctor of Technical Sciences, the founder of the company, Oleksandr Vereshchinskyi, and the commercial director of OLIS Ltd, Volodymyr Cheglatoniev, we are going into production. The company built its own plant in 2018, taking into account all modern requirements. The equipment was transferred to the new facilities and subsequently, preferring to improve the processes, the machine-building industry was re-armed on a large scale using the latest technology.

There is a working atmosphere inside the enterprise: there are many orders, so it is necessary to fulfill them in a timely manner and send them to customers.

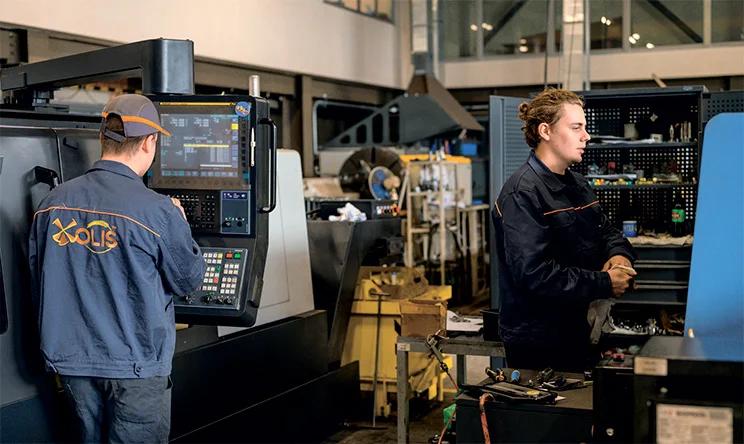

In the blanks department, operators work on the most modern equipment, in particular, with the help of laser machines, they cut parts, then presses give them the necessary shape, and in the metalworking and welding shop, they assemble assemblies from them, which later become a finished product.

“The overwhelming majority of us work on German TRUMPF equipment. And for mechanical processing, we use South Korean DOOSAN units,” says Oleksandr Vereshchinskyi.

“We don’t even think about reducing costs. After all, the quality and reliability of our equipment is a priority,” he adds.

The separate pride of the enterprise is its own scientific research center. New grain processing technologies are developed here and existing ones are improved. The equipment will not be put into mass production without comprehensive research: first at the factory, where it is operated under load on a test stand, and then at powerful enterprises specializing in grain processing.

First steps

In the early 2000s, large processing enterprises collapsed, and small companies appeared en masse, producing products with significant losses. Therefore, the market lacked equipment designed for small volumes of production.

“We tried to create something new in grain processing. This was the path of gradual improvements, as a result of which new machines appeared. As a result, our equipment became more productive and less energy-intensive,” emphasized Oleksandr Vereshchinskyi.

Volodymyr Cheglatoniev said that initially “OLIS” was an engineering company with very strong technologists. After all, technologists are the generators of ideas for improving and creating new equipment.

“We started with the reconstruction of grain factories and mills. Having extensive experience in re-equipment and improvement of structures of other manufacturers, they began to build grain processing plants on the basis of equipment of their own development.

Brain center

Oleksandr Vereshchinskyi considers his team to be his greatest asset. Now the company has 200 employees: talented specialists united by the desire to change machine-building for the better.

A separate role in the company’s success was played by the combination of a scientific and practical approach and the ability to unite talented people in one common cause.

In particular, Yury Pyrus, a fellow student of Oleksandr Vereshchinskyi, has been working as the director of development and implementation at OLIS Ltd for 12 years in a row, a practitioner with extensive experience in the implementation of buckwheat and oat processing.

“With Yury Bohdanovich, we raised highly qualified grain processing technologists who work for us. After all, technologists are our brain center.

According to him, if new directions are opened in the company, first of all they attract first-class technologists.

A wide spectrum

Currently, the company produces about 200 types of equipment for cleaning, processing and quality control of grain, which from 2021 will be marked with a single OLIS logo for domestic and foreign markets.

A breakthrough in the Ukrainian market was the LUCH ZSO line of drum separators, consisting of seven models of different performance. In particular, “LUCH-300” with a capacity of more than 300 t/h works at the Starokonstantinovsky MEZ, “Transgrain Terminal” in Chernomorsk and other enterprises in Ukraine and abroad.

Also, the company produces three models of SKO drum scalpers – machines intended for the selection of large impurities. Unlike “LUCH”, this equipment has fewer sections.

In the end, the customers pushed the specialists of the OLIS company to develop Horizont-K flat screen separators.

“Today we produce six models of such separators. These machines have also proven themselves very well,” noted Volodymyr Cheglatoniev.

Usually, developers first create equipment of lower performance and subsequently design more powerful machines. In OLIS with flat-screen separators, the opposite happened: first they developed “Horizont-K” with a capacity of 40 tons, and later, based on the needs of the market, they introduced a line of three PSO models, where the best technological solutions of large “Horizonts” were embodied in low-capacity machines.

The company has special machines that clean hard-to-separate impurities – triers, indented cylinder TCK and TCO, destoners, without which no processor can do. Also, ” OLIS ” offers vibropnevmastoly.

“Our line of grain cleaning equipment is really wide,” Volodymyr Cheglatoniev emphasized.

Among the developers, close attention is paid to quality control of grain and its processing products. The results of the applied efforts are embodied in more than 20 names of laboratory instruments.

“Our equipment is used in small farms, elevators and processing enterprises of holdings, and even in port terminals. We will find a solution for everyone. Technical specialists of “OLIS” work daily to make our technologies more reliable and durable. The best proof is that some of our clients have had equipment that has been working without breakdowns for about 20 years,” said the company’s commercial director.

For his part, Oleksandr Vereshchinskyi noted that new developments of devices and technologies are very expensive, but OLIS is consciously going for it, because development is impossible without improvements.

“We prefer to deal with the business that we know very well,” he concluded.

COMMENT

Volodymyr Cheglatoniev, commercial director of OLIS Ltd

Our equipment works in 35 countries around the world. On average, customers from 20 different countries buy OLIS equipment every hour.

Now, in almost every country of the European Union, we have partners who offer our equipment and provide service.

Also, OLIS machines work in Canada and the USA, the countries of Central Asia and even in Turkey, a country with its own powerful machine-building industry.

All foreign companies with whom they worked before the war express their trust in us and, despite the possible risks, buy OLIS equipment. We are grateful to them for their support and greatly appreciate our partnership.

Oleksandr Vereshchinskyi, Doctor of Engineering, founder of the OLIS company

The domestic market is the most reliable partner of our company. Business prefers to buy Ukrainian equipment, which is not inferior in quality to foreign analogues. Therefore, I am grateful to domestic agricultural producers and processors who find resources and order our products.

Thanks to constant feedback from customers, we understand the needs of the industry. This encourages OLIS to improve. We do not just sell equipment, our goal is to become a part of the customer’s technological process, the success of which is our success.

AGRO TIMES – https://agrotimes.ua/article/yakist-pidtverdzhena-chasom/